Single anode shunt and regulation apparatus electrolyzed by multiple anodes cell and method

A control device and multi-anode technology, applied in the electrolysis process, electrolysis components, etc., can solve the problems of power factor reduction, damage to electrolysis cells, electrolysis equipment, energy consumption, etc., to improve current efficiency, reduce heat income, prolong The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

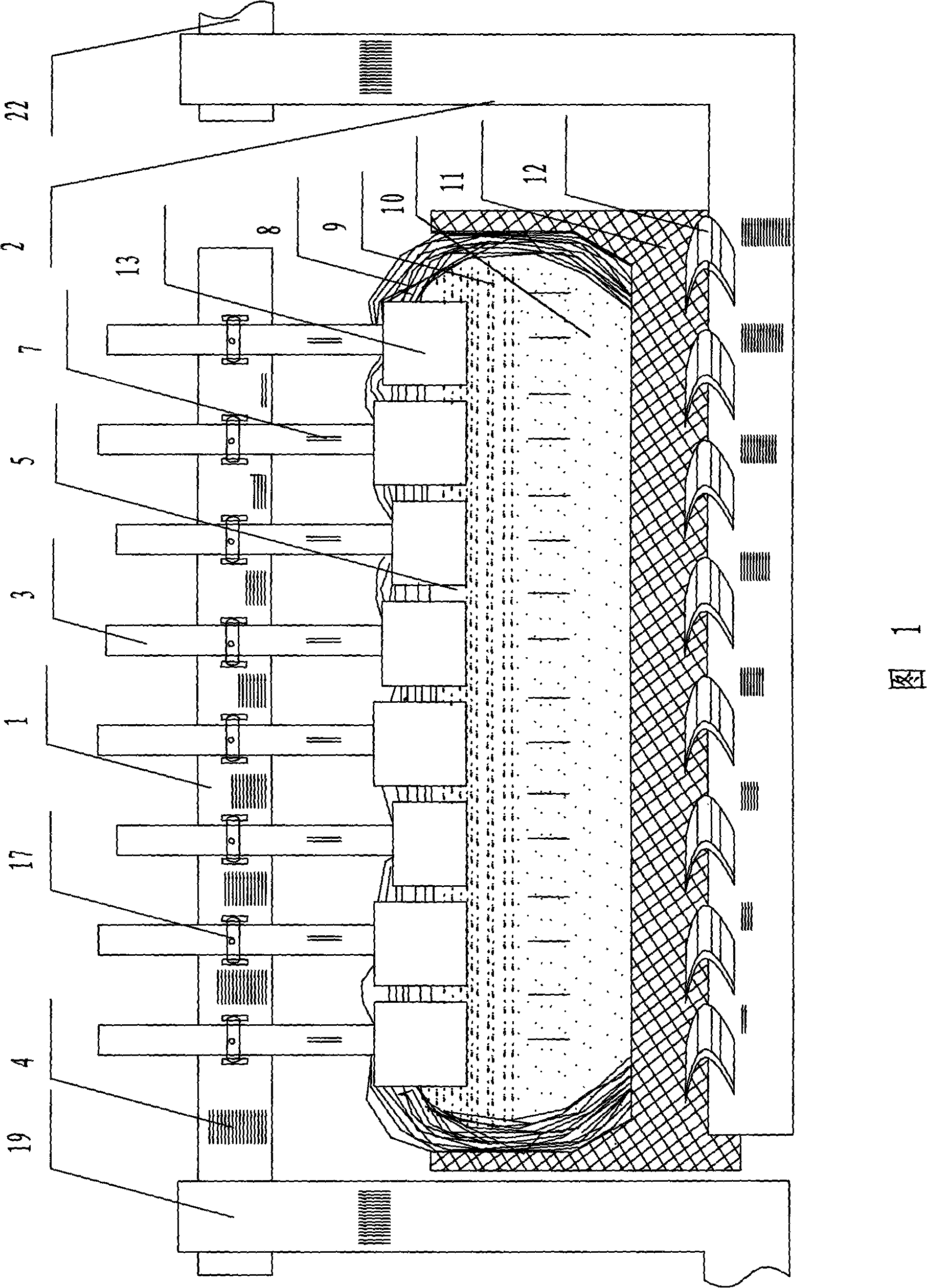

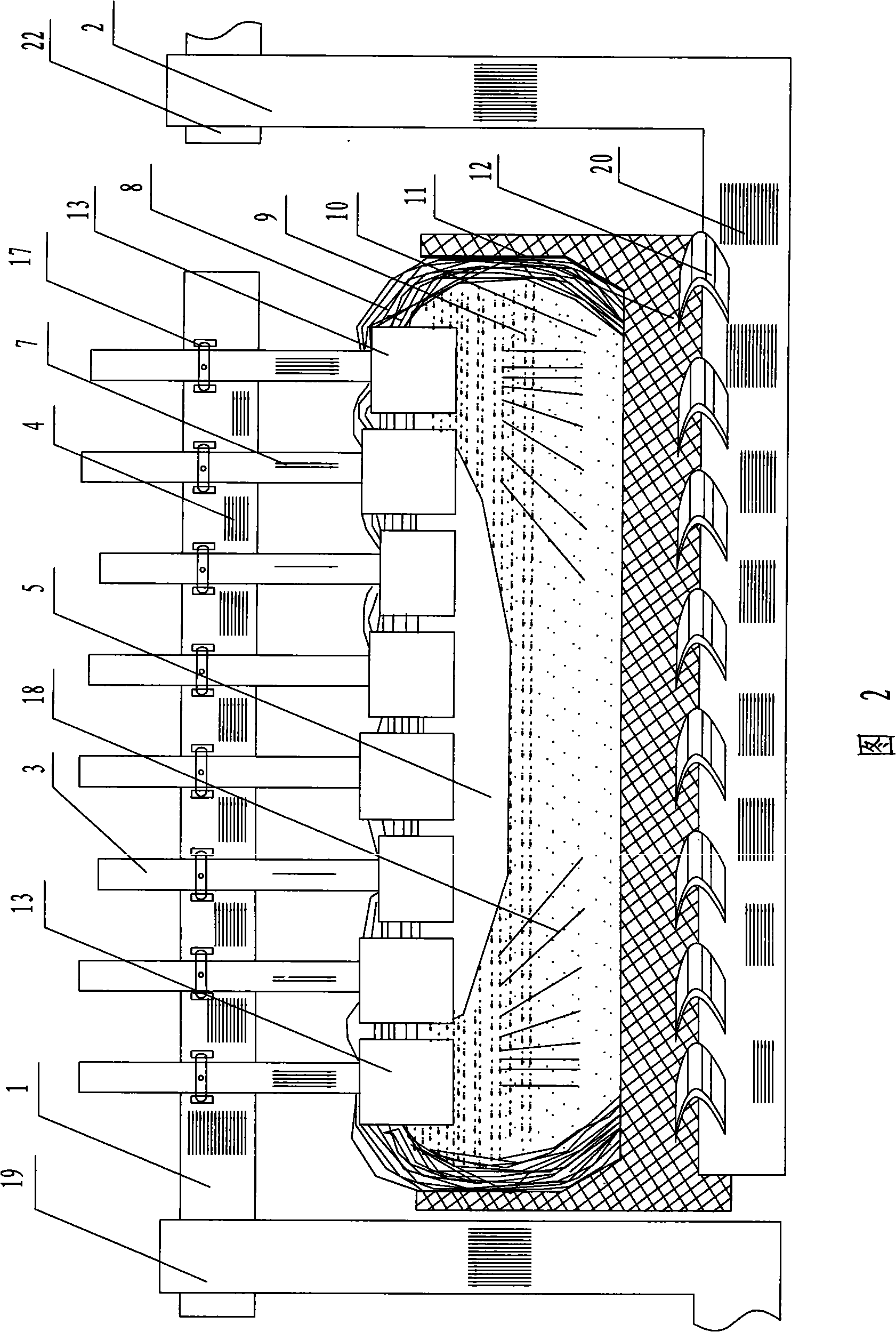

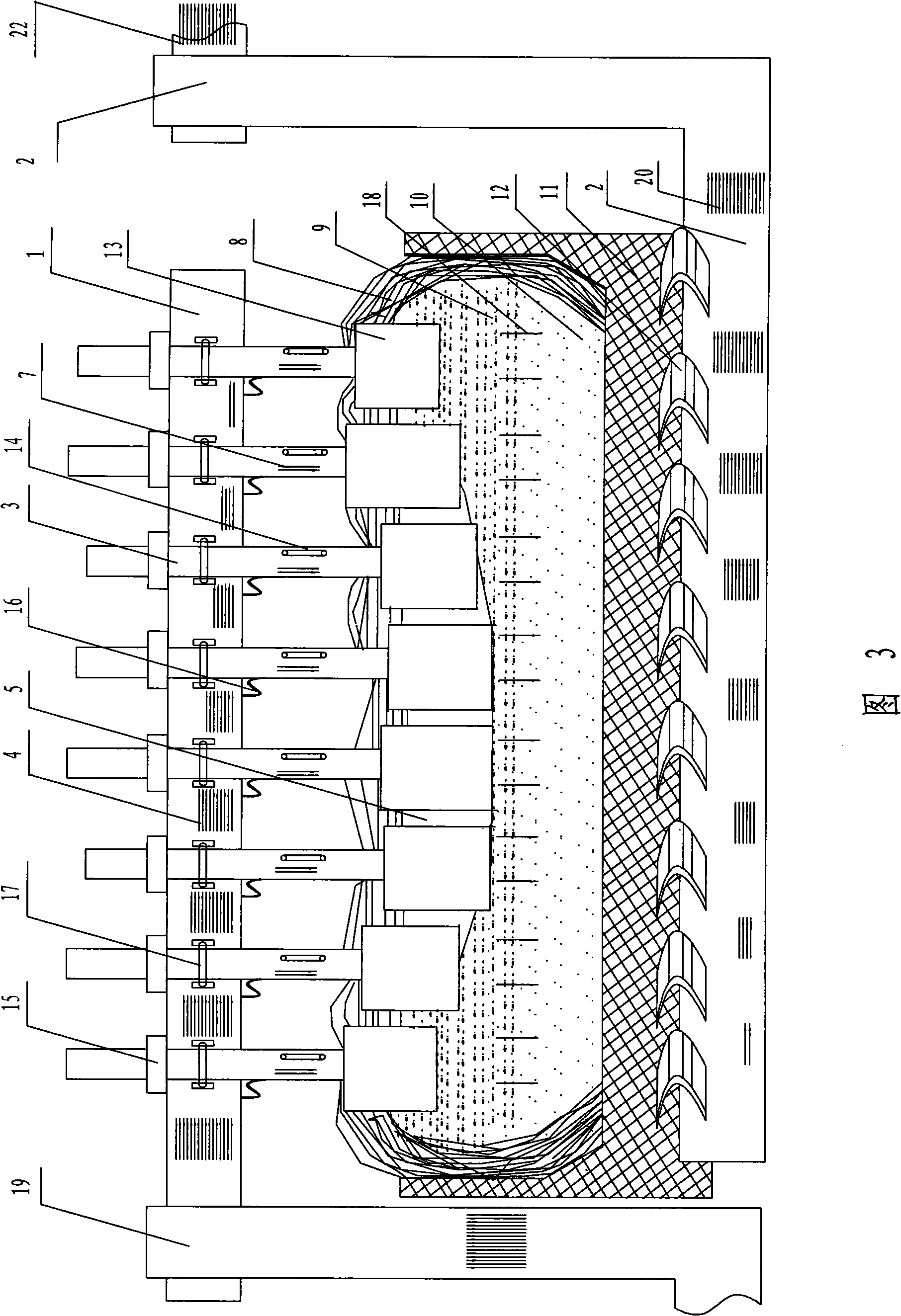

[0048] Embodiment one: see Fig. 3, Figure 4 , a single anode shunt control device for multi-anode electrolysis, the upper end of the electrolytic cell has an anode unit, the lower end has a cathode unit, and an electrolyte 9 and an aluminum liquid 10 between the anode unit and the cathode unit in the electrolytic cell, the anode The unit includes an anode bus bar 1, a certain number of anode groups installed vertically on the anode bus bar 1, each anode group includes an anode guide rod 3, and an anode carbon block 13 is fixed on each anode guide rod 3, and each anode The guide rods 3 are individually movable and installed on the anode bus bar 1, and an anode guide rod control device 15 is installed on each anode guide rod 3, which is used to adjust the height of each anode guide rod 3, and at the same time adjust the anode carbon block 13 and the electrolyte 9; and a lead wire 16 is connected in parallel between the anode bus bar 1 and each anode guide rod 3 to realize a soft...

Embodiment 2

[0055] Embodiment 2: The accompanying drawings are not drawn, and the meaning is basically the same as that of Embodiment 1, and the similarities will not be repeated. The difference is that the anode guide rod is set in the mounting hole of the anode guide rod control device, and is kept in contact with the anode guide rod by a pressing device. The anode bus bar is in contact, the anode guide rod control device is fixed on the anode bus bar, and the anode guide rod control device uses a gear reduction system to control the movement of the anode guide rod.

[0056] One end of the softly connected lead is fixed on the anode bus bar through a compression mechanism, and the other end is fixed on the anode guide rod by welding, and is fixed in the full current section between the compression device and the current detection of the anode guide rod.

Embodiment 3

[0057] Embodiment three: see Figure 5 , the numbers are the same as those in Embodiment 1, the meanings are the same, and the same parts will not be repeated. The difference is that one end of the wire 16 of the flexible connection is fixed on the anode busbar 1 through the pressing mechanism 6, and the other end is fixed through the pressing mechanism 21 It is on the anode guide rod 3 and fixed on the full current section between the current detection device 14 at the contact point between the anode guide rod and the anode bus bar.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com