Iron-based amorphous alloy powder, iron-based amorphous alloy coating and preparation method thereof

A technology of iron-based amorphous alloy and powder, which is applied in the field of preparation of this kind of amorphous alloy powder and amorphous coating, can solve the limitation of practical application, and the preparation technology of amorphous alloy coating has not obtained a wide range of research and practice. Application and other issues, to achieve excellent wear-resistant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

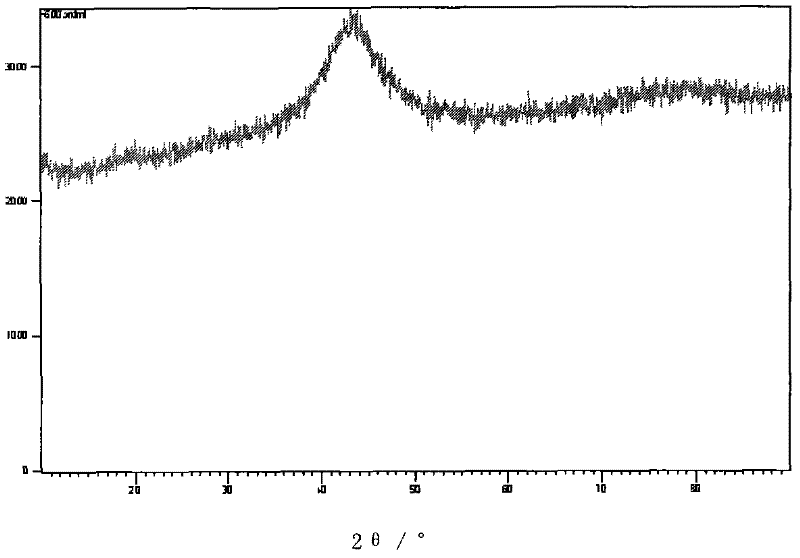

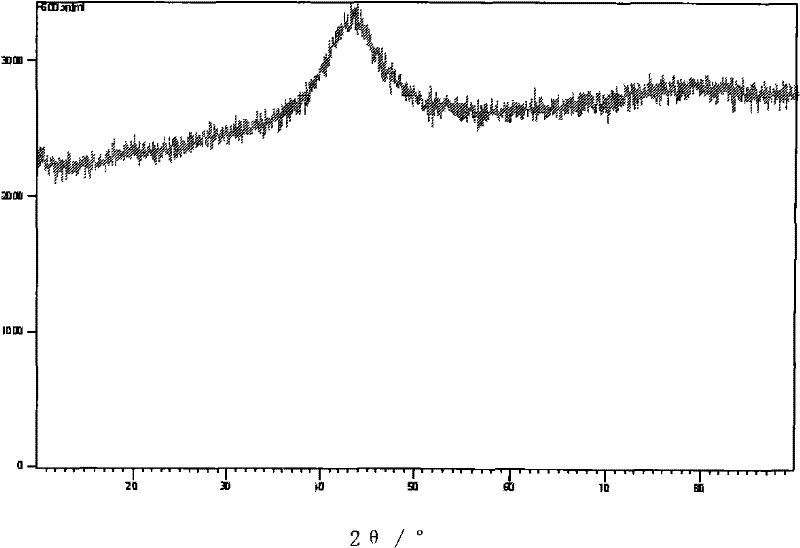

[0028] The design alloy composition is Fe 49.5 Cr 15 Mo 14 Y 0.5 C 15 B 6 (at.%), the master alloy was prepared by vacuum induction melting; the amorphous alloy powder was prepared by ultra-high pressure inert gas atomization technology. Its X-ray diffraction results are as follows figure 1 shown. It shows that the alloy powder is completely amorphous.

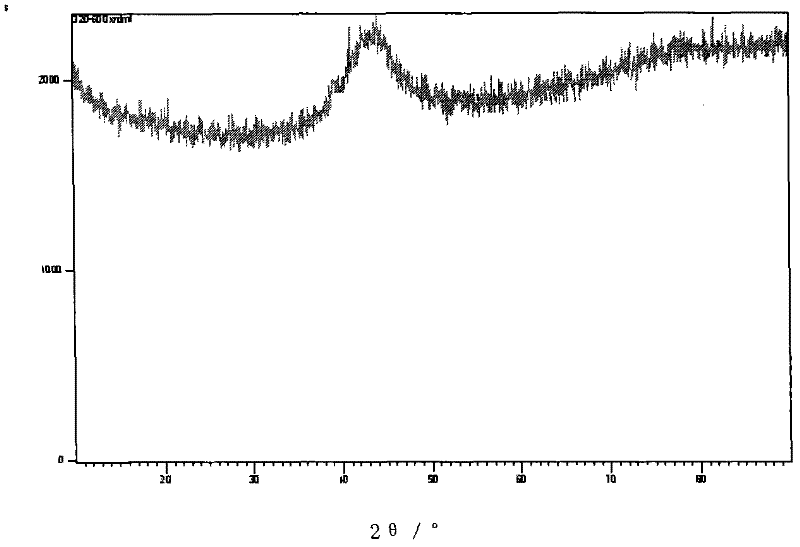

[0029] The above-mentioned amorphous alloy powder is sieved, and the particle size of the powder for spraying is selected to be less than 45 μm. Nitrogen is used as the powder feeding gas and powder accelerating gas, the temperature is 300°C, and the nitrogen pressure is 5MPa. The X-ray diffraction results of the coating are as follows figure 2 shown. Indicates that the coating is a completely amorphous coating.

Embodiment 2

[0031] The design alloy composition is Fe 50 Cr 17.5 Mo 7 Si 3 mn 2 W 2 B 15 C 3.5(at.%), the master alloy was prepared by vacuum induction melting; the amorphous alloy powder was prepared by ultra-high pressure inert gas atomization technology. X-ray diffraction results show that the alloy powder is completely amorphous.

[0032] The above-mentioned amorphous alloy powder is sieved, and the particle size of the powder for spraying is selected to be <50 μm. Use helium as the powder feeding gas and powder accelerating gas, the temperature is 500°C, and the nitrogen pressure is 2MPa. The X-ray diffraction results of the coating show that the coating is a completely amorphous coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com