Feeding pressure and pressing pressure linkage type pressure filter control method and high-pressure pressure filter

A technology of feeding pressure and control method, applied in the field of high-pressure filter press, can solve problems such as filter plate damage, and achieve the effects of increasing feeding pressure, simple control, and improving the ability of material to separate filtrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

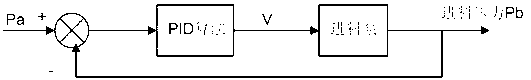

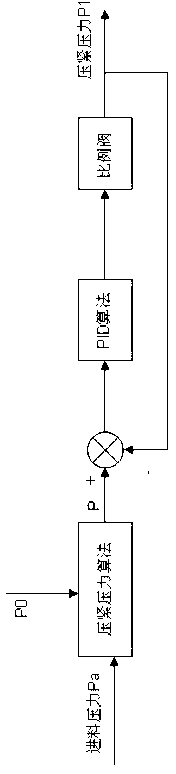

[0025] see Figure 1 to Figure 4 , the present embodiment feed pressure and compression pressure linkage filter press control method, including

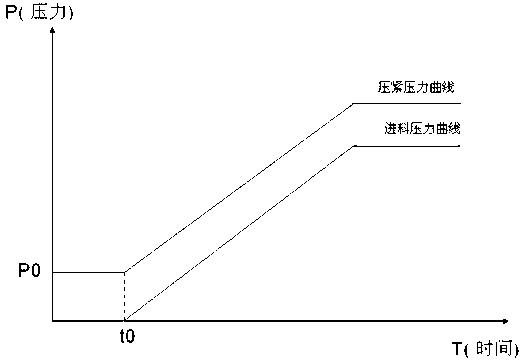

[0026] a) Before feeding, apply a compaction pre-pressure to the filter press to maintain the sealing state of the filter plate when the filter press is empty;

[0027] b) Start feeding, as the material continues to fill the filter chamber of the filter press, the feed pressure in the filter chamber increases continuously, and the compaction pressure applied to the filter press also increases correspondingly according to a certain ratio.

[0028] In the process of increasing the feed pressure in this embodiment, the feed pressure is closed-loop controlled through the PID ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com