plastic extruder barrel

A plastic extruder and barrel technology, applied in the field of plastic extruders, can solve the problems of reducing production efficiency and achieve the effects of improving production efficiency, increasing feed pressure, and facilitating replacement and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

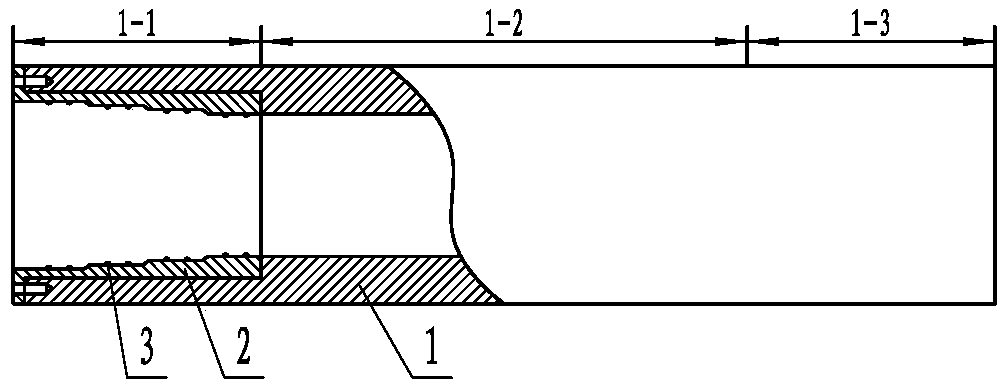

[0014] figure 1 The barrel of the plastic extruder shown includes a barrel 1, and the barrel 1 has a feeding section 1-1, a plasticizing section 1-2 and a homogenizing section 1-3, and the feeding section 1-1 has a The sleeve body 2 is provided with a shoulder to limit and position the sleeve body 2 in the cylinder body 1, and the sleeve body 2 is fixed in the cylinder body 1 through a plurality of bolts; The inner diameter of the steps decreases toward the homogenization section 1-3, and the inner diameter of the last step is the same as that of the plasticizing section 1-2 of the cylinder body 1, and the steps are connected by inclined planes to avoid jamming; sleeve body 2 There are also a plurality of hemispherical bumps 3 distributed on the inner wall.

[0015] When working, the material enters the screw groove of the feeding section 1-1 from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com