Quick agar gelling method

A gel and agar technology, applied in the field of agar rapid gelation, can solve the problems of high comprehensive energy consumption, low production efficiency, unstable gel quality, etc., and achieve high heat exchange intensity, simple structure and reasonable design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1. Pre-cooling the agar solution: filter the agar solution with a mass concentration of 2.0% obtained by boiling the gelatin to remove impurities, and use a heat exchanger to lower the temperature of the agar solution to 55°C.

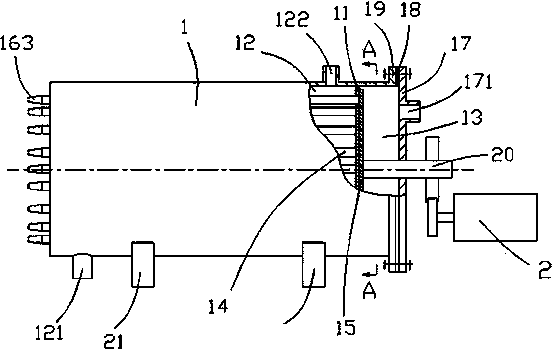

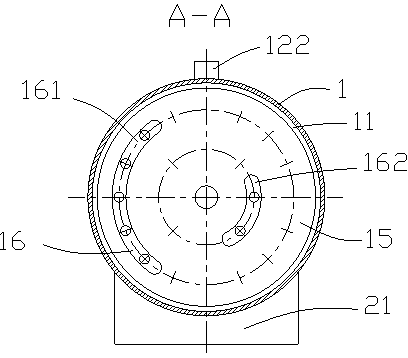

[0033] 2. Gel and pushing strips: the rotary table glue injection type gel pushing strip machine completes the gelation of the pre-cooled glue and outputs strip-shaped gels. The glue enters the feeding chamber 13 from the feeding port 171, and the batching turntable 15 rotates at a speed of 2rpm, so that the outer arc-shaped elongated hole 151 and the inner arc-shaped elongated hole 152, which are arranged oppositely, are respectively outwardly condensing the tube 161 and the inner condensing pipe 161. Pipe 162 intermittently injects glue solution to increase the supply pressure to promote the formation of gel. The glue solution exchanges heat with the cooling water flowing in the opposite direction at 25°C to cool and gradually gel. , the strip...

Embodiment 2

[0036] 1. Pre-cooling the agar solution: filter the agar solution with a mass concentration of 1.0% obtained by boiling the gelatin to remove impurities, and use a heat exchanger to lower the temperature of the agar solution to 38°C.

[0037]2. Gel and pushing strips: the rotary table glue injection type gel pushing strip machine completes the gelation of the pre-cooled glue and outputs strip-shaped gels. The glue enters the feed chamber 13 from the feed port 171, and the batching turntable 15 rotates at a speed of 6 rpm, so that the outer arc-shaped long hole 151 and the inner arc-shaped long hole 152 that are arranged oppositely on the outer condensing pipe 161 and the inner condensing pipe 161 respectively Pipe 162 intermittently injects glue solution to increase the supply pressure to promote the formation of gel. The glue solution exchanges heat with the cooling water flowing in the opposite direction at 15°C to cool and gradually gel. , the strip-shaped gel is removed fr...

Embodiment 3

[0040] 1. Pre-cooling the agar solution: filter the agar solution with a mass concentration of 0.5% obtained by boiling the gelatin to remove impurities, and use a heat exchanger to lower the temperature of the agar solution to 27°C.

[0041] 2. Gel and pushing strips: the rotary table glue injection type gel pushing strip machine completes the gelation of the pre-cooled glue and outputs strip-shaped gels. The glue enters the feeding chamber 13 from the feeding port 171, and the batching turntable 15 rotates at a speed of 10 rpm, so that the outer arc-shaped elongated hole 151 and the inner arc-shaped elongated hole 152 that are relatively arranged on it are respectively outwardly condensing the pipe 161 and internally condensing Pipe 162 intermittently injects glue solution to increase the supply pressure to promote the formation of gel. The glue solution exchanges heat with the cooling water flowing in the opposite direction at 2°C to cool and gradually gel. , the strip ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com