Treatment method for biodiesel waste water

A technology of biodiesel and treatment methods, applied in biological water/sewage treatment, special compound water treatment, water/sewage treatment, etc., can solve the problem that the pretreatment and regulating tanks cannot meet the requirements of biochemical system water intake, and the quality and quantity of wastewater are not enough Rule fluctuations, energy saving and emission reduction are not feasible, etc., to achieve the effect of unattended, short commissioning cycle, and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

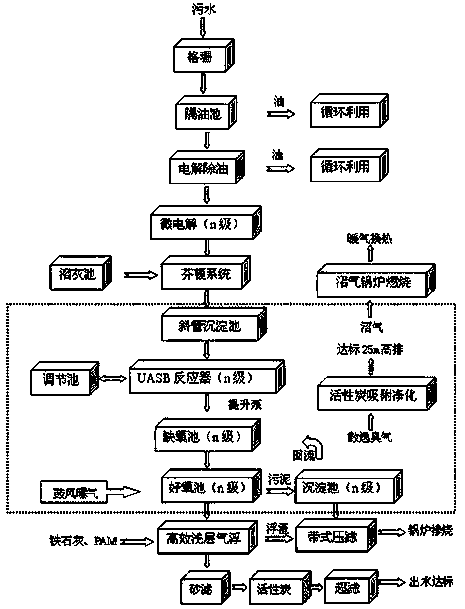

Image

Examples

example 1

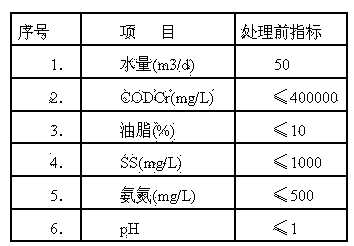

[0038] Example 1. Raw water situation:

[0039]

[0040] Apply the treatment method of the biodiesel wastewater of the present invention for treatment. Grease trap 3 levels, hydraulic retention time 2 days; 10V voltage electrolysis 10min; micro-electrolysis residence 2h, Fenton residence 2h, hydrogen peroxide dosage 1‰, two-stage UASB residence time 2d; two-stage anaerobic residence 1d; two-stage aerobic Stay for 8 days; micro-flocculation PAM is 10PPM, iron lime is 50PPM. The wastewater treatment effect of each unit is shown in Table 1.

example 2

[0041] Example 2, raw water situation:

[0042]

[0043] Apply the treatment method of the biodiesel wastewater of the present invention for treatment. Grease trap level 5, hydraulic retention time 3 days; 12V voltage electrolysis 20min; micro-electrolysis two-stage residence 3h, Fenton residence 2h, hydrogen peroxide dosage 1‰, three-stage UASB residence 3d; two-stage anaerobic residence 1d; The aerobic residence time is 10d; the microflocculation PAM is 20PPM, and iron lime is 100PPM. The wastewater treatment effect of each unit is shown in Table 2.

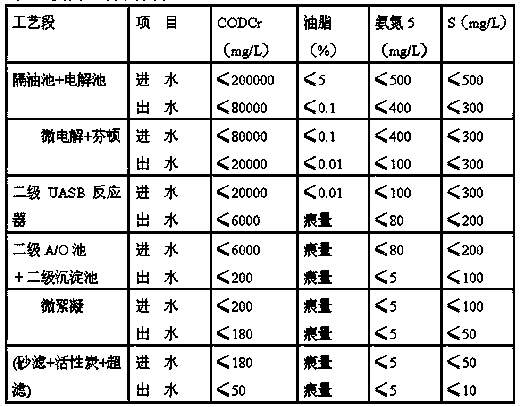

[0044] Table 1 Effect Analysis of Example 1

[0045]

[0046] Table 2 Effect Analysis of Example 2

[0047]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com