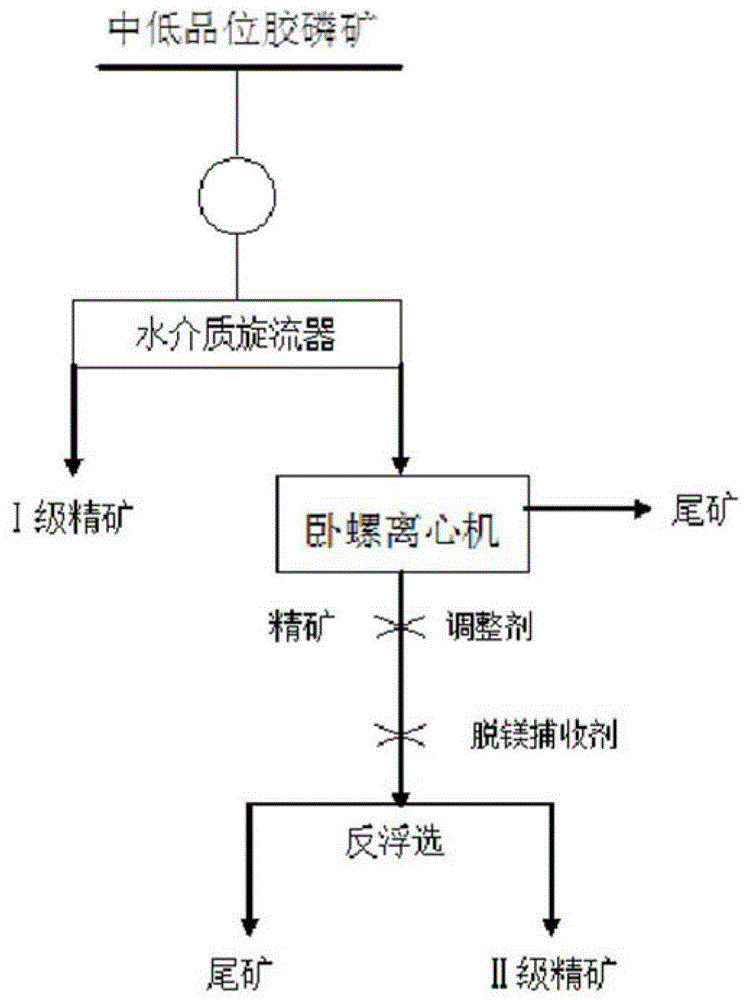

Process method for removing phosphate impurities by combining gravity, centrifugal force and flotation

A process method and centrifugal force technology, applied in the collophosite field, can solve the problems such as the unreported industrial process of ore dressing, and achieve the effects of improving the grade of phosphate rock, increasing the recovery rate, and reducing the consumption of chemicals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0024] Operate according to the following steps:

[0025] ⑴ will contain P 2 o 5 It is 22%~25% collophosite wet ground to a fineness of -200 mesh 85%~90%, and a slurry with a solid content of 30%~35%;

[0026] ⑵Put the ore slurry into the water medium cyclone, and the ore feeding pressure is 1.5kg / cm 2 ~2.5kg / cm 2 ;

[0027] ⑶Water medium cyclone tailings at 70~85m 3 / h is fed into the decanter centrifuge; the drum speed of the decanter centrifuge is 2200r / min; the differential speed between the drum and the screw is 40r / min;

[0028] (4) Phosphoric acid is added to the concentrate of the decanter centrifuge to adjust the pH value of the pulp to 4~5;

[0029] ⑸The adjusted ore pulp enters the flotation machine, and at the same time, add sodium linoleate, a collector for magnesium removal, at a dosage of 500g / T, which is aerated and foamed.

[0030] Get Grade I Concentrate P 2 o 5 content of 30.0%~31.5%, MgO content of 0.9%~1.5%, R 2 o 3 The content is 1.2%~1.5%; Gra...

Embodiment 3

[0032] Operate according to the following steps:

[0033] ⑴ will contain P 2 o 5 It is 23%~25% collophosite wet ground to a fineness of -200 mesh 75%~85%, and a slurry with a solid content of 35%~40%;

[0034] ⑵Put the ore slurry into the water medium cyclone, and the ore feeding pressure is 1.5kg / cm 2 ~2.5kg / cm 2 ;

[0035] ⑶Water medium cyclone tailings at 60~80m 3 / h is fed into the decanter centrifuge; the drum speed of the decanter centrifuge is 1800r / min; the differential speed between the drum and the screw is 25r / min;

[0036] (4) Fluosilicic acid is added to the concentrate of the decanter centrifuge to adjust the pH value of the pulp to 4~5;

[0037] (5) The adjusted ore pulp enters the flotation machine, and at the same time, add the magnesium removal agent sodium stearate, the dosage is 600g / T, after aeration, scrape foam.

[0038] Get Grade I Concentrate P 2 o 5 content of 29.0%~31.5%, MgO content of 0.7%~1.0%, R 2 o 3 The content is 1.2%~1.8%; Grade II...

Embodiment 4

[0040] Operate according to the following steps:

[0041] ⑴ will contain P 2 o 5 Wet grinding of 23%~26% collophosite to a slurry of -200 mesh 90%~95% with a solid content of 20%~25%;

[0042] ⑵Put the ore slurry into the water medium cyclone, and the ore feeding pressure is 1.5kg / cm 2 ~2.5kg / cm 2 ;

[0043] ⑶Water medium cyclone tailings at 85~100m 3 / h is fed into the decanter centrifuge; the drum speed of the decanter centrifuge is 1500r / min; the differential speed between the drum and the screw is 10r / min;

[0044] (4) Sulfuric acid is added to the concentrate of the decanter centrifuge to adjust the pH value of the pulp to 4~5;

[0045] (5) The adjusted ore pulp enters the flotation machine, and at the same time, add the magnesium removal agent sodium oleate, the dosage is 450g / T, after aeration, scrape foam.

[0046] Get Grade I Concentrate P 2 o 5 content of 30.0%~31.0%, MgO content of 0.8%~1.4%, R 2 o 3 The content is 1.4%~1.8%, the grade II concentrate P 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com