Printing head and three-dimensional printing machine

A technology of 3D printers and print heads, which is applied in the direction of processing and manufacturing, coating devices, manufacturing tools, etc., can solve the problems of reducing printing quality, achieve the effects of improving printing quality, meeting high-speed printing requirements, and reducing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

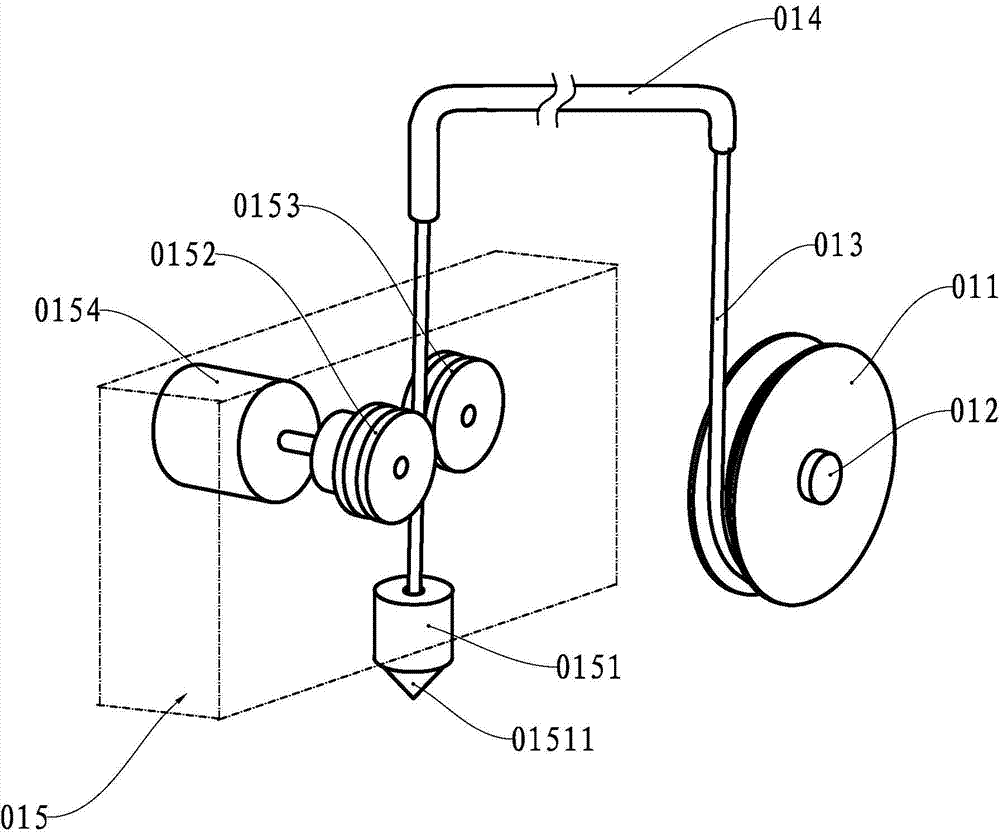

[0029] see Figure 4, The print head is composed of a printing nozzle 1, a hose 2, a heater 3, a feeding device 4, a cooling device 5 and a feeding pressure device 6. The outlet of the heater 3 communicates with the inlet of the printing nozzle 1 through the hose 2, which is a high-temperature-resistant lightweight hose, and is used to heat the molten material in the heating and melting chamber 31 of the heater 3 to a molten state. The molding material is introduced into the printing nozzle 1; the feeding device 4 has a pair of feeding rollers located near the feeding port of the heater 3, and is used to feed the fine material on the filament box of the 3D printer under the control of the 3D printer controller. The wire is sent into the heating and melting chamber 31 at a certain rate; the cooling device 5 has a fan 51, and the airflow generated by the rotation of the fan 51 is used to regulate the temperature of the heater 3 and the connection between the heater 3 and the fee...

no. 2 example

[0031] As an explanation of the second embodiment of the print head of the present invention, only the differences from the above first embodiment of the print head will be described below.

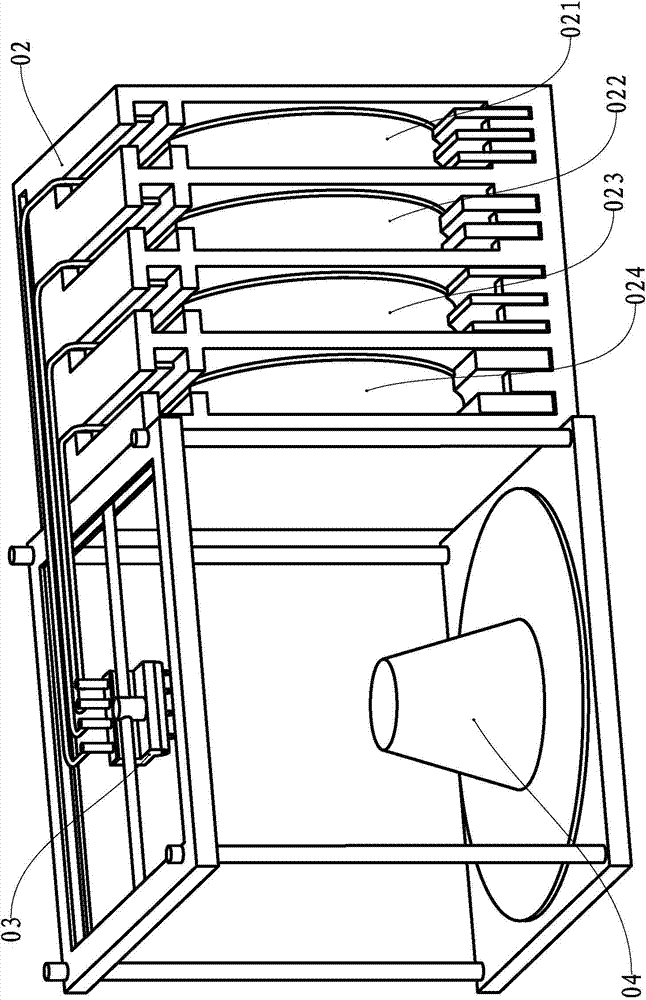

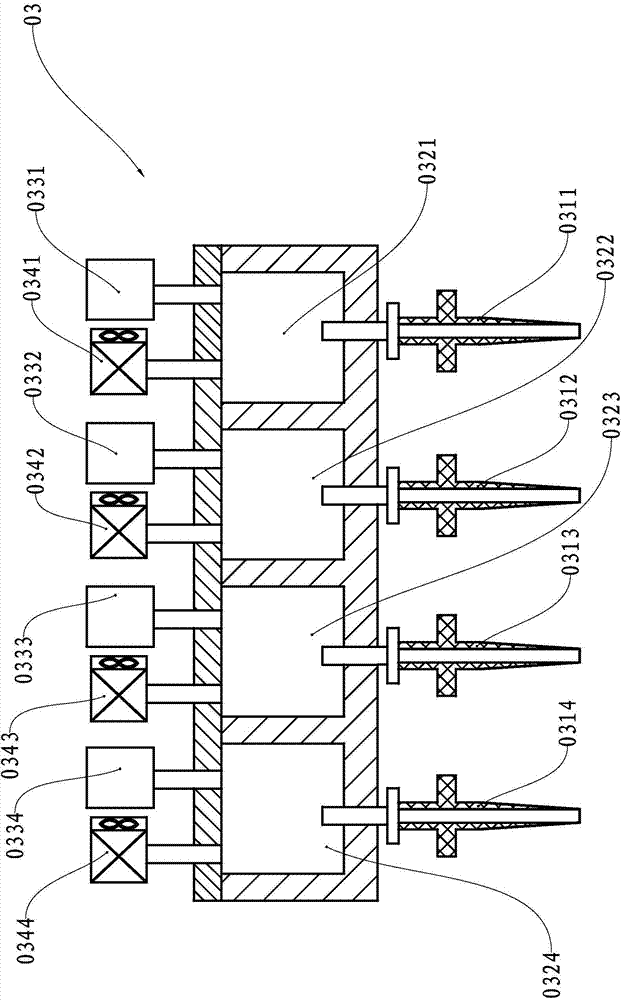

[0032] see Figure 5 and Image 6 , the number of printing nozzles, hoses, heating and melting chambers of heaters, feeding devices, cooling devices and feeding pressure devices of the printing head in this example are four, which are respectively printing nozzles 211, 212, 213 and 214, soft Tubes 221, 222, 223 and 224, heating and melting chambers 231, 232, 233 and 234 of heaters, feeding devices 241, 242, 243 and 244, cooling devices 251, 252, 253 and 254, and feed pressure devices 261 . The form connects the print nozzle and the heater.

no. 3 example

[0034] As a description of the third embodiment of the present invention, only the differences from the first embodiment of the above-mentioned print head will be described below. The print head of this example is also provided with a negative pressure device for providing a heating and melting chamber for the heater. Negative pressure, after the target molding is printed, the molding material in the printing nozzle and hose is sucked back into the heating and melting chamber, which effectively prevents the residual molding material from condensing in the hose and printing nozzle, hindering subsequent printing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com