Power battery protection structure of new energy automobile

A technology of new energy vehicles and power batteries, applied in batteries, structural parts, electric vehicles, etc., can solve problems such as external short circuit, temperature rise, endangering the personal safety of passengers, etc., to suppress vibration, ensure accuracy, and avoid the spread of fire Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

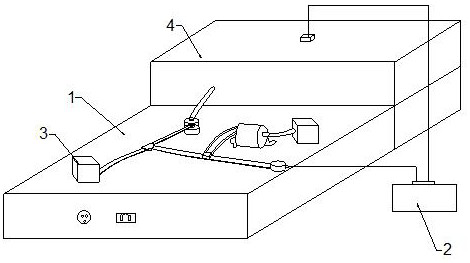

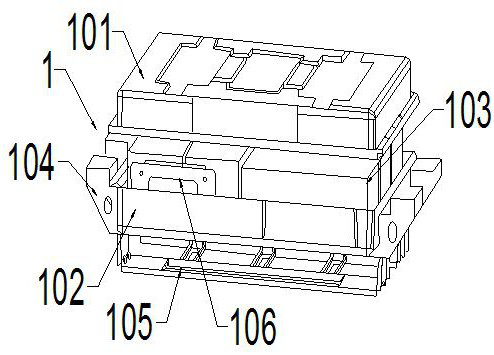

[0044] combine figure 1 , a new energy vehicle power battery protection structure, including a battery compartment 1 and at least one battery module 103 uniformly arranged in the battery compartment 1, including a pressure regulating mechanism 3 and a fire protection mechanism 4 disposed on the battery compartment 1, The pressure regulating mechanism 3 and the fire prevention mechanism 4 are all connected to the central controller 2, and the central controller adopts a model of STM32 as a processor chip, and realizes data communication through the RS485 serial port. Multi-directional monitoring and real-time monitoring of air tightness and fire, timely warning and alarm in case of fire, avoiding missed reports and reducing false alarms, automatic fire extinguishing in time, and effective control of fire, maintaining the air pressure in the battery compartment Stablize.

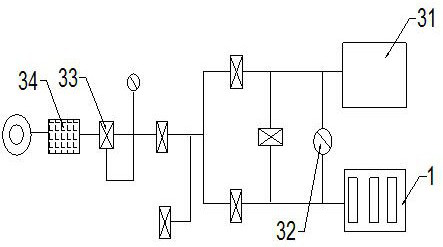

[0045] combine image 3 , the pressure regulating mechanism 3 includes a standard part 31, a differential...

Embodiment 2

[0047] On the basis of Example 1, under the premise that the volume of the standard part and the battery compartment are the same, the influence of temperature on the leakage of the medium gas in the battery compartment satisfies: ΔP=ΔP 0 [1+(T-T 0 -273) / (T 0 +273)]; where, ΔP is the pressure drop value in the battery compartment measured by the differential pressure sensor when the temperature is T, ΔP 0 for the set temperature T 0 The standard pressure drop value in the standard part.

[0048] The medium gas medium in the battery compartment is air. Under the same conditions as the battery compartment and standard parts, the symmetry of the battery compartment and standard parts and the symmetry of the solenoid valve group connected to them can eliminate the impact caused by the change of external temperature. The difference between the two, so that the differential pressure sensor can accurately measure the airtightness in the battery compartment.

Embodiment 3

[0050] combine figure 1 and Figure 4 , a new energy vehicle power battery protection structure, including a battery compartment 1 and at least one battery module 103 uniformly arranged in the battery compartment 1, including a pressure regulating mechanism 3 and a fire protection mechanism 4 disposed on the battery compartment 1, The fire prevention mechanism 4 includes a fire extinguisher 41 connected to the battery compartment 1 and at least one compound detection unit 42 arranged inside the battery compartment 1. The accuracy of the information obtained is guaranteed by the compound detection units arranged at different positions in the battery compartment. The detection unit completes the collection and processing of fire information, reduces the burden on the controller, and transmits it to the fire alarm central controller through the RS485 bus, timely and effectively distinguishes and performs preprocessing work and alarms in the early stage of fire, so as to avoid the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com