Protective film for STP building exterior wall thermal-insulation fire-retardant material

A technology for flame-retardant materials and building exterior walls, which is applied in the direction of heat preservation, building components, layered products, etc., and can solve the problem of affecting the heat insulation and heat preservation effect of finished STP building exterior wall panels, the surface flatness is not high, and the production process is difficult. and other problems, to achieve excellent barrier effect, good flatness effect, and good dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

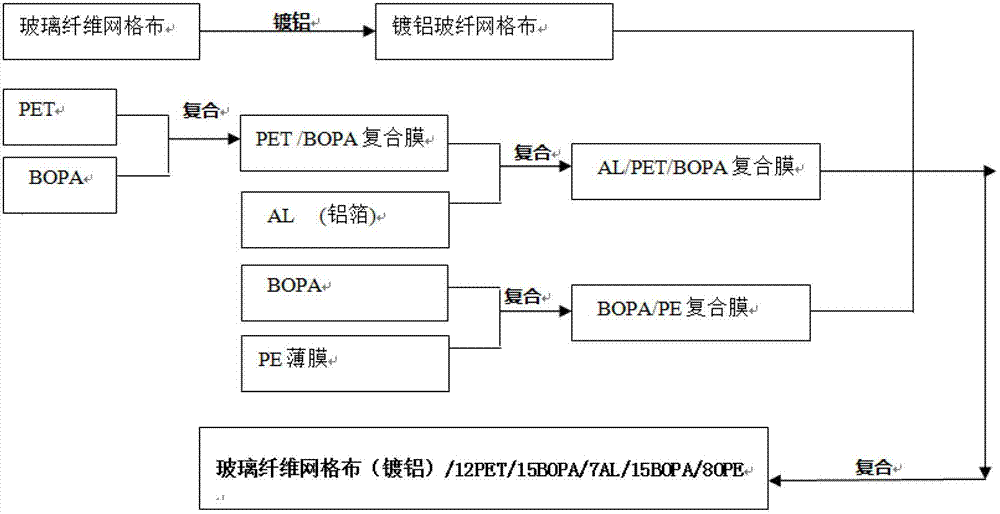

[0046] Such as image 3 , the present invention includes the following steps:

[0047] a) Glass fiber mesh cloth aluminum plating process,

[0048] b) AL / PET / BOPA composite process,

[0049] c) BOPA / PE composite process,

[0050] d) Composite process of aluminized glass fiber mesh cloth / PET / BOPA / AL / BOPA / PE;

[0051] The c) BOPA / PE composite process includes the preparation process of PE. In the preparation process,

[0052] The outer layer is blended and extruded from 40%m-LLDPE DOW5100+50%MDPE2038.68G+10%LDPE150BW.

[0053] The middle layer is blended and extruded from 70% HDPE HTA108+30% m-LLDPE 1018FA.

[0054] The inner layer is blended and extruded from 30% LDPE 150BW+70% m-LLDPE PL1881G.

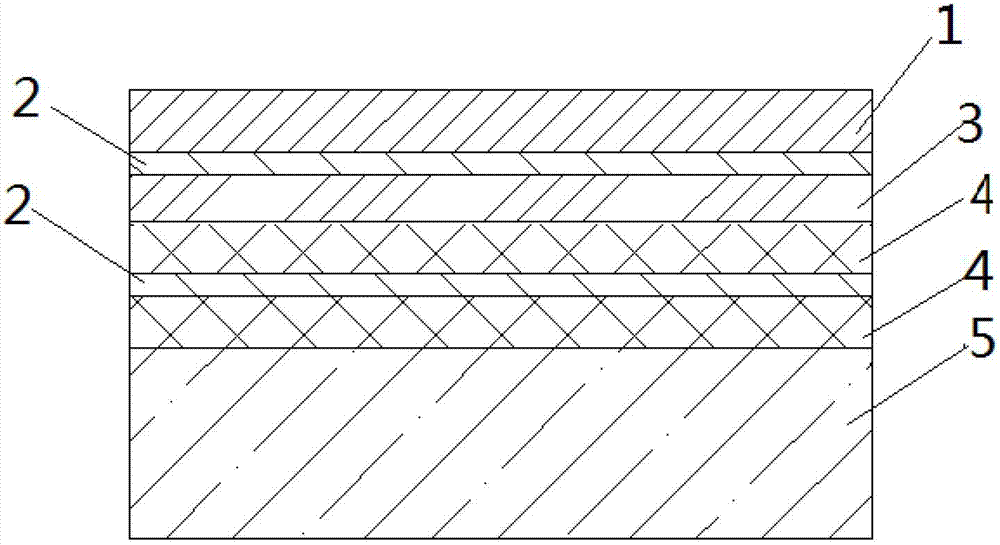

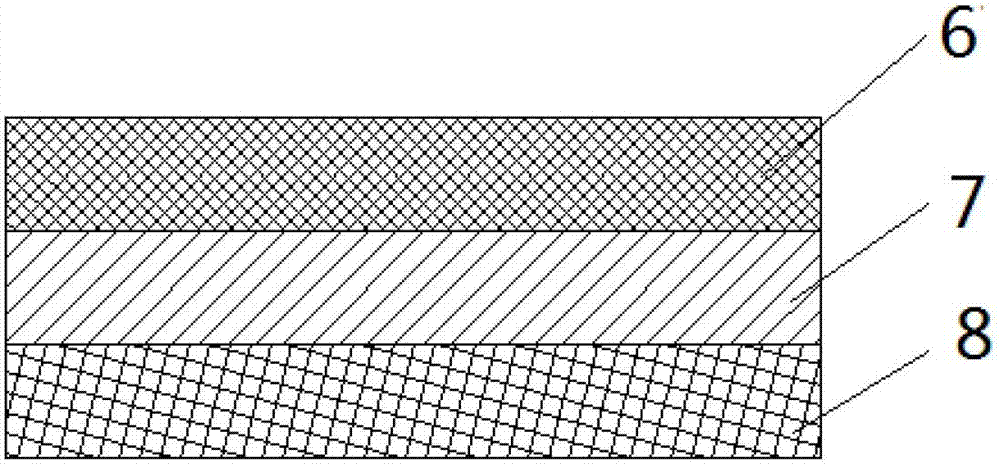

[0055] Depend on figure 1 , 2 As shown, the film is made from outside to inside aluminized glass fiber mesh cloth 1 / 7um aluminum layer 2 / 12um PET polyester layer 3 / 15um biaxially stretched nylon layer 4 / 7um aluminum layer 2 / 15um biaxially stretched nylon Layer / 80um composite pol...

Embodiment 2

[0057] In addition to the c) BOPA / PE composite process, including the preparation process of PE, in the preparation process,

[0058] The outer layer is blended and extruded from 50% m-LLDPE DOW5100 + 40% MDPE2038.68G + 10% LDPE150BW.

[0059] The middle layer is blended and extruded from 60% HDPE HTA108+35% m-LLDPE 1018FA and 5% methyl syringate.

[0060] The inner layer is blended and extruded from 33.3% LDPE 150BW+66.7% m-LLDPE PL1881G.

[0061] Outside, all the other are identical with embodiment 1.

Embodiment 3

[0063] In addition to the c) BOPA / PE composite process, including the preparation process of PE, in the preparation process,

[0064] The outer layer is blended and extruded from 45%m-LLDPE DOW5100+45%MDPE2038.68G+10%LDPE150BW.

[0065] The middle layer is blended and extruded from 90% HDPE HTA108+10% m-LLDPE 1018FA.

[0066] The inner layer is blended and extruded from 33.3% LDPE 150BW+66.7% m-LLDPE PL1881G.

[0067] Outside, all the other are identical with embodiment 1.

[0068] The technical effect of embodiment 1,2,3 is as follows:

[0069]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com