Ore grinding granularity online prediction system and method

A forecasting system and ore grinding technology, applied in general control systems, control/regulation systems, instruments, etc., can solve problems such as large lag, low model performance, and large computing resources

- Summary

- Abstract

- Description

- Claims

- Application Information

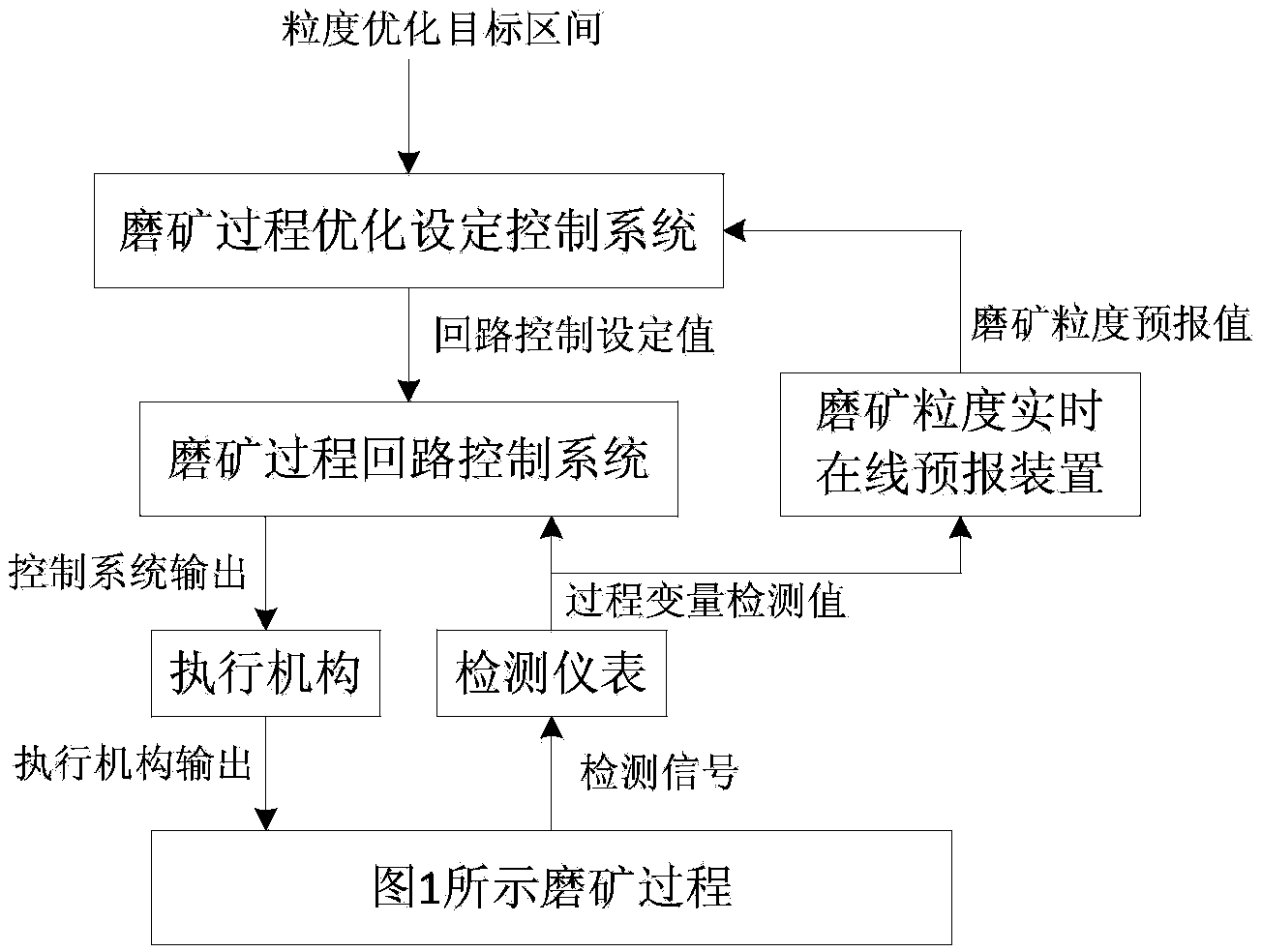

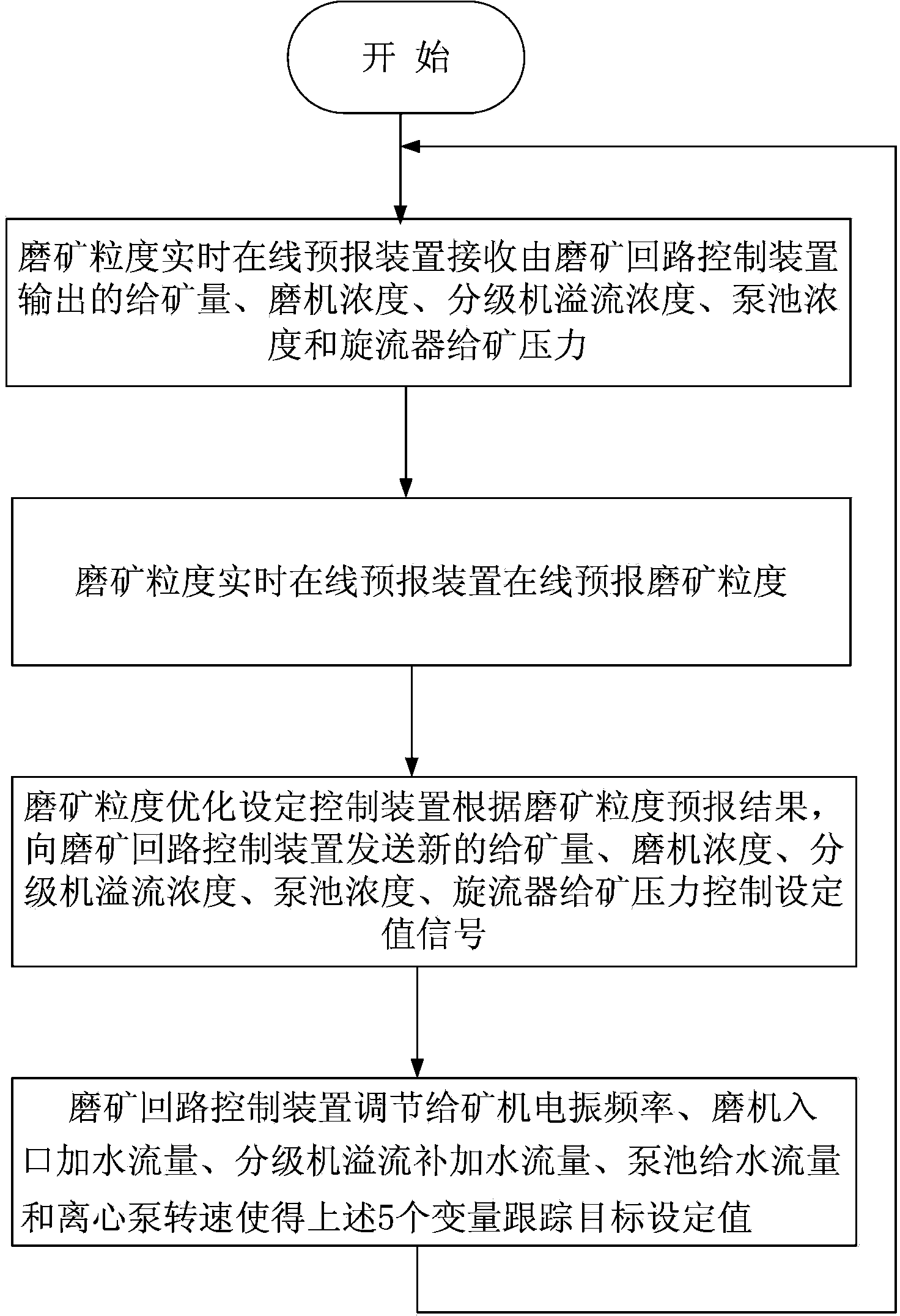

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

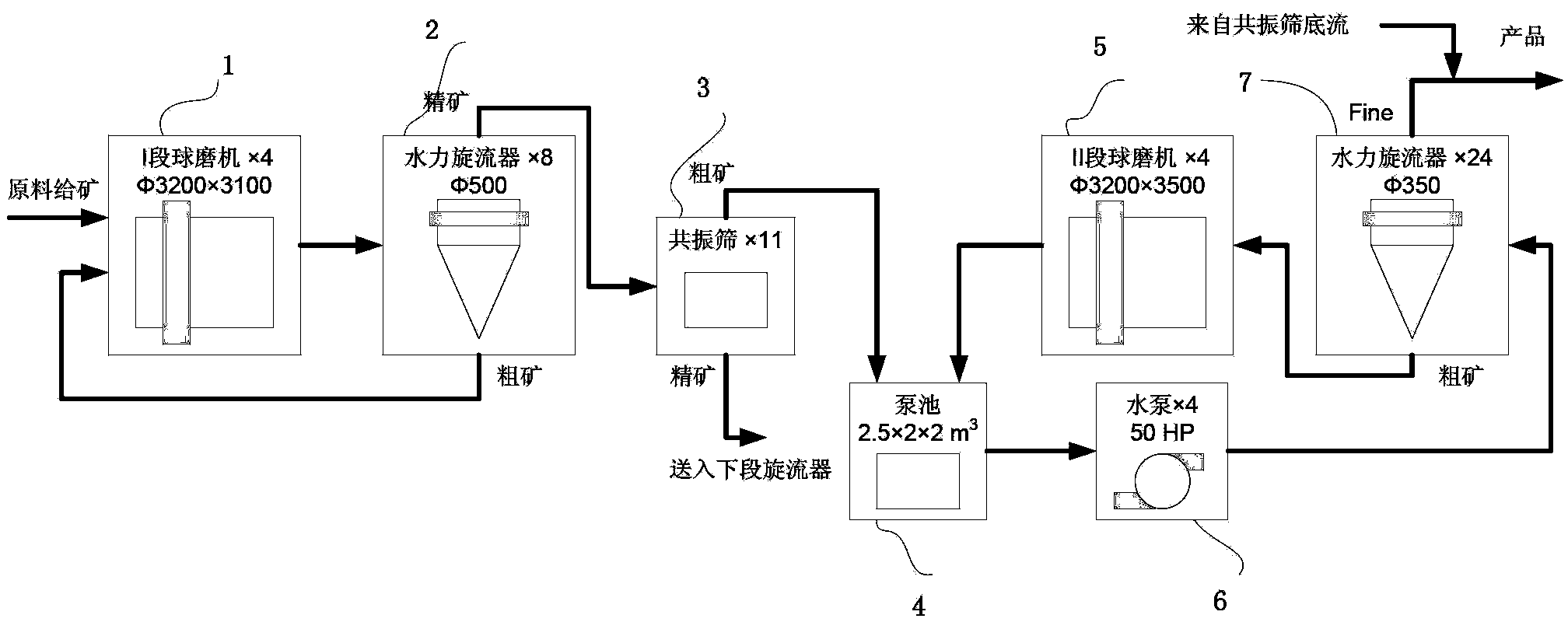

[0047] figure 1 Shown is a schematic diagram of the grinding circuit process of the embodiment of the present invention. This embodiment includes two grinding circuits, the first circuit is composed of 4 ball mills 1 with a diameter of 3200*3100mm and 8 hydrocyclones 2 with a diameter of 500mm; the second circuit is composed of 4 diameters of 3200mm *3100mm two-stage ball mill 5, a group of 12 centrifugal water pumps 6 and 24 hydrocyclones 7 with a diameter of 350mm. Its technological process is:

[0048] First, the raw ore is continuously conveyed to a conveyor belt through a vibrating feeder, which is mixed with water required for grinding, and these materials are mainly provided for a section of ball mill 1 for grinding. The mud in the first section of ball mill 1 is mixed with dilution water and then output to the first group of hydrocyc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com