Reactive dye composition and dyeing method using the same

A technology of reactive dyes and compositions, applied in the fields of dyeing, organic dyes, textiles and papermaking, etc., can solve the problems of insufficient solubility, difficult practical application, poor reproducibility, etc., and achieve good reproducible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] Composition of reactive dyes

[0078] The compounding composition of the reactive dye is shown in Table 1.

[0079] [Table 1] Compound composition

[0080] Compounding example 1 of the present invention brown

[0081] red reactive dye

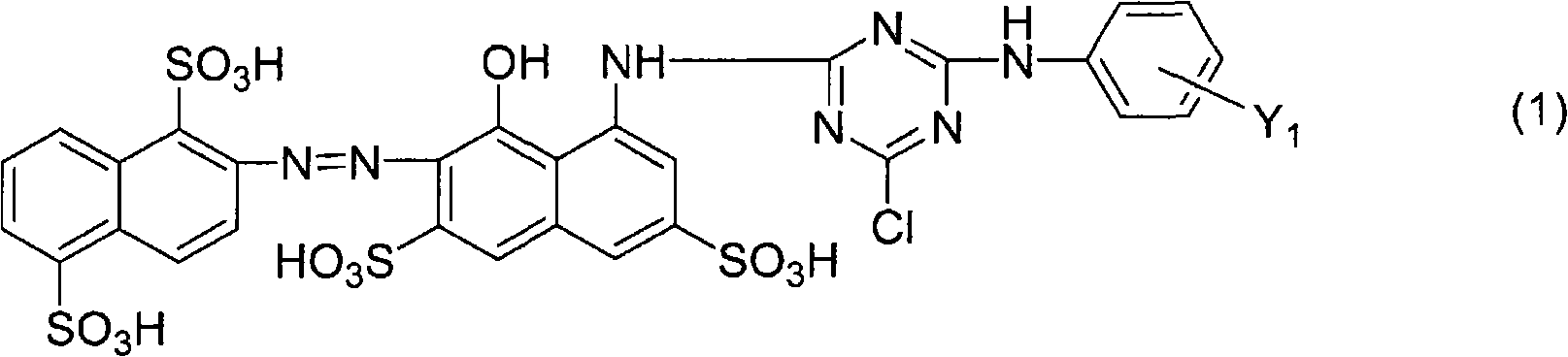

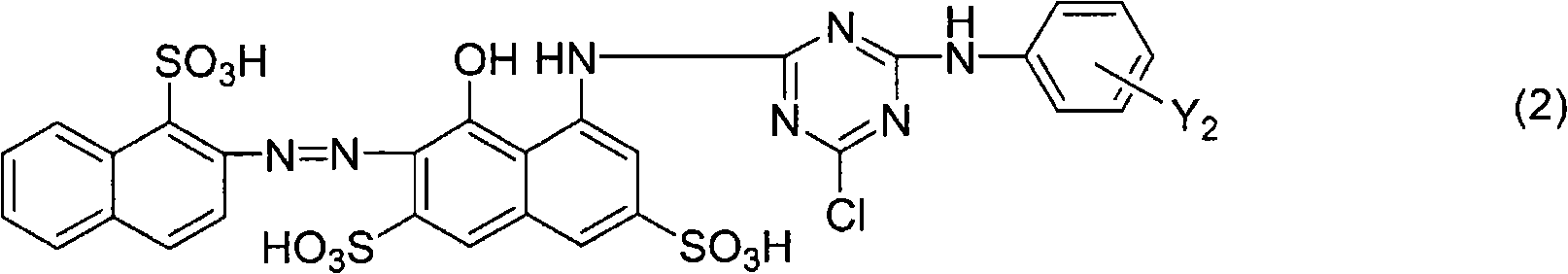

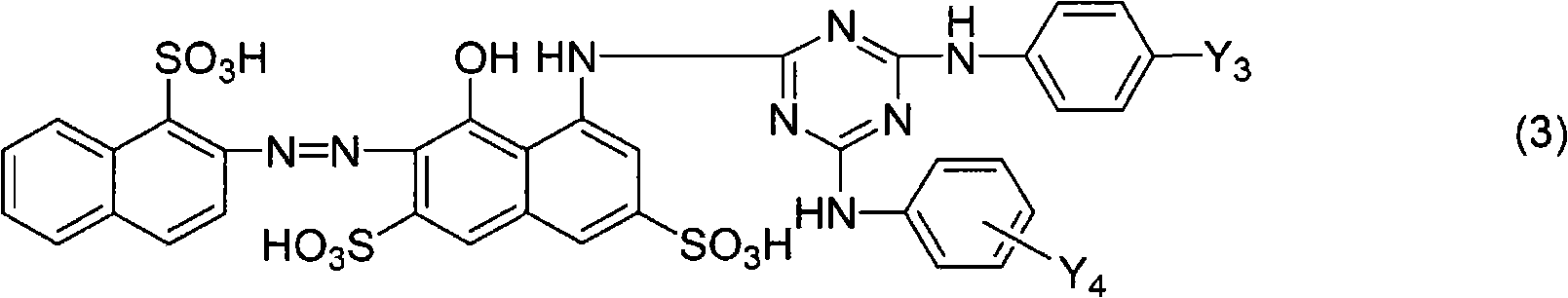

[0082] 0.10 parts of the dyestuff of formula (1)

[0083] 0.18 part of the dyestuff of formula (2)

[0084] 0.10 parts of the dyestuff of formula (3)

[0085] blue reactive dye

[0086] 0.27 parts of the dyestuff of formula (4)

[0087] 0.10 parts of the dyestuff of formula (5)

[0088] 0.14 parts of the dyestuff of formula (6)

[0089] yellow reactive dye

[0090] 1.26 parts of the dyestuff of formula (8)

[0091] Coordination example 2 of the present invention brown

[0092] red reactive dye

[0093] 0.12 parts of the dyest...

Embodiment 2

[0152] Composition of reactive dyes

[0153] The compounding composition of the reactive dye is shown in Table 3.

[0154] [table 3]

[0155] Coordination example 5 of the present invention brown

[0156] red reactive dye

[0157] 0.29 parts of the dyestuff of formula (1)

[0158] 0.56 part of the dyestuff of formula (2)

[0159] 0.29 parts of the dyestuff of formula (3)

[0160] blue reactive dye

[0161] 0.31 part of the dyestuff of formula (4)

[0162] 0.83 parts of the dyestuff of formula (5)

[0163] 0.39 parts of the dyestuff of formula (6)

[0164] yellow reactive dye

[0165] 3.78 parts of the dyestuff of formula (8)

[0166] Compounding example 6 of the present invention brown

[0167] red reactive dye

[0168] 0.26 part of the dyestuff of formula (1)

[0169] ...

Embodiment 3~ Embodiment 12

[0230] Using the combination and usage amount of the dyes shown in Table 5 instead of the combination and usage amount of Compounding Example 1 in Example 1, water was added to 15 parts of anhydrous sodium sulfate to prepare a total of 490 parts of dye baths. 50 parts of knitted cotton fabrics were placed in this dye bath, and the temperature was raised to 60° C. over 20 minutes. After treating at 60°C for 10 minutes, add 10 parts of sodium carbonate and dye at the same temperature for 60 minutes. Then, after washing with water and hot water, saponify at 100° C. for 15 minutes in 500 parts of an aqueous solution containing a commercially available saponification agent (Skoalol C-1200, manufactured by Kitahiro Chemical Co., Ltd., 1 g / L), and then perform Washing with water and drying to obtain a dyed product.

[0231] [Table 5] Compound composition

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com