Nanometer modifying apparatus of metal material surface

A metal material and nanotechnology, which is applied in the field of metal material surface nanometerization devices, can solve the problems of inability to realize continuous and large-scale production, large surface roughness of samples, and difficulty in large-scale equipment, so as to achieve reasonable design and small roughness , strong practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

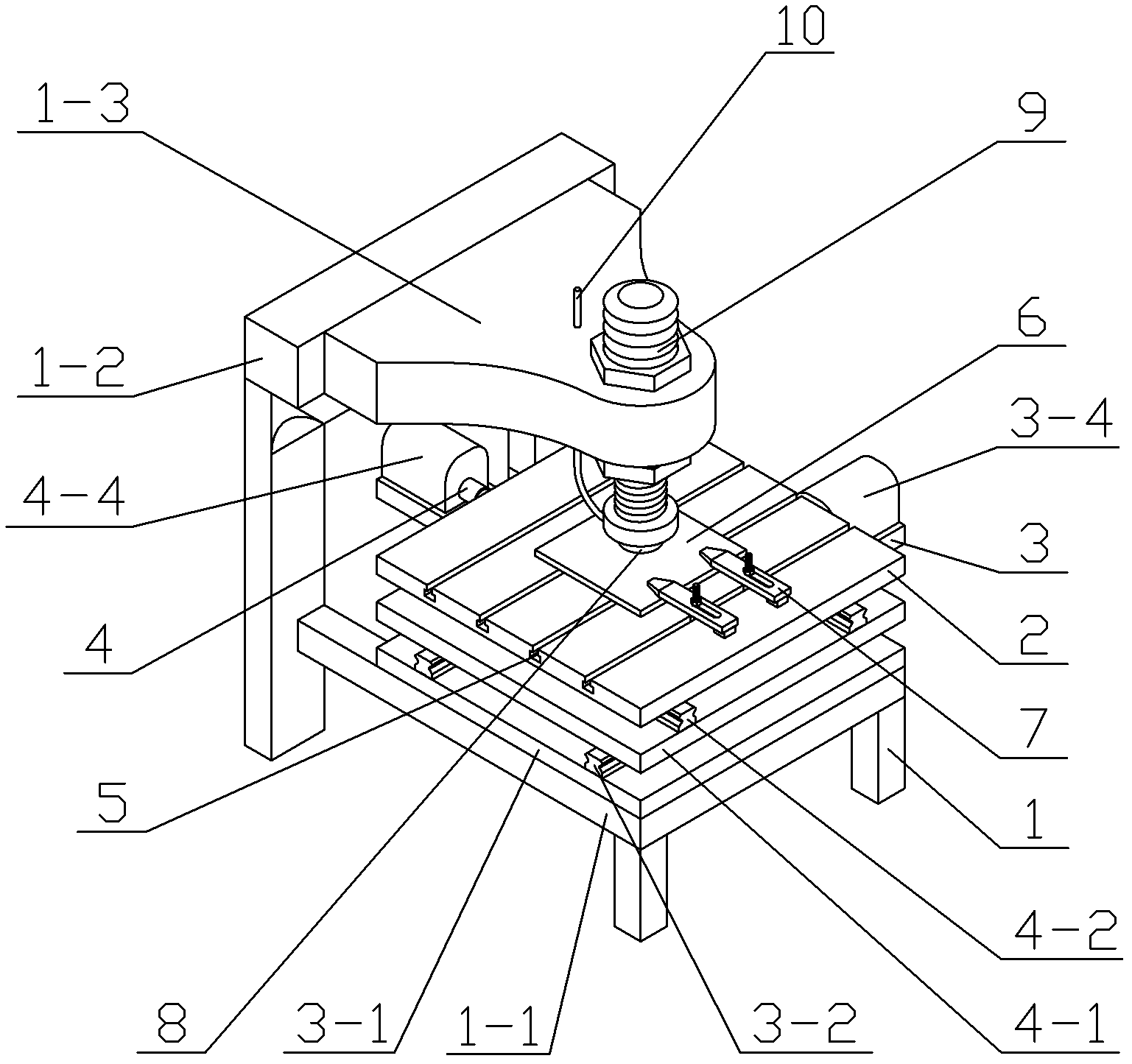

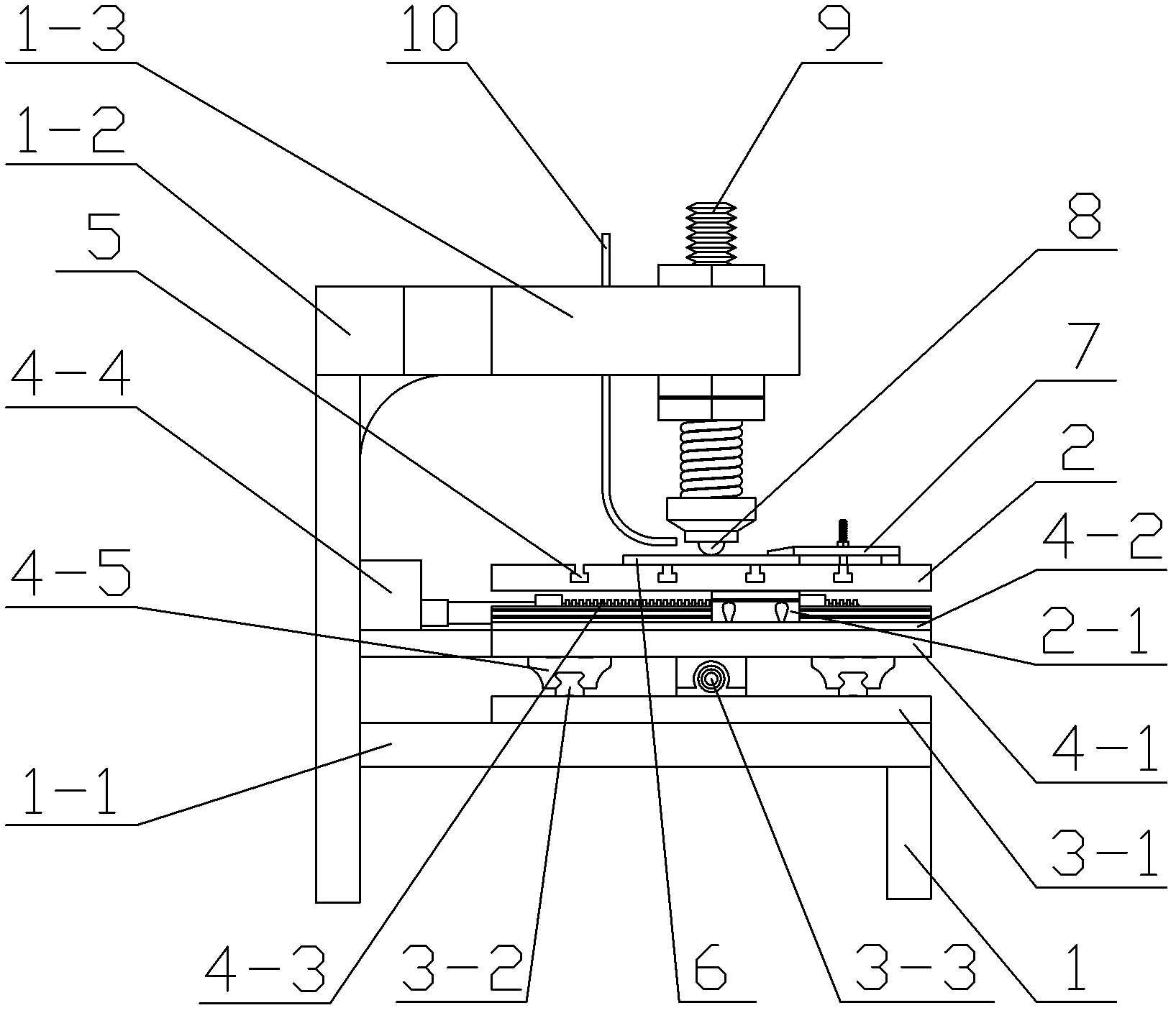

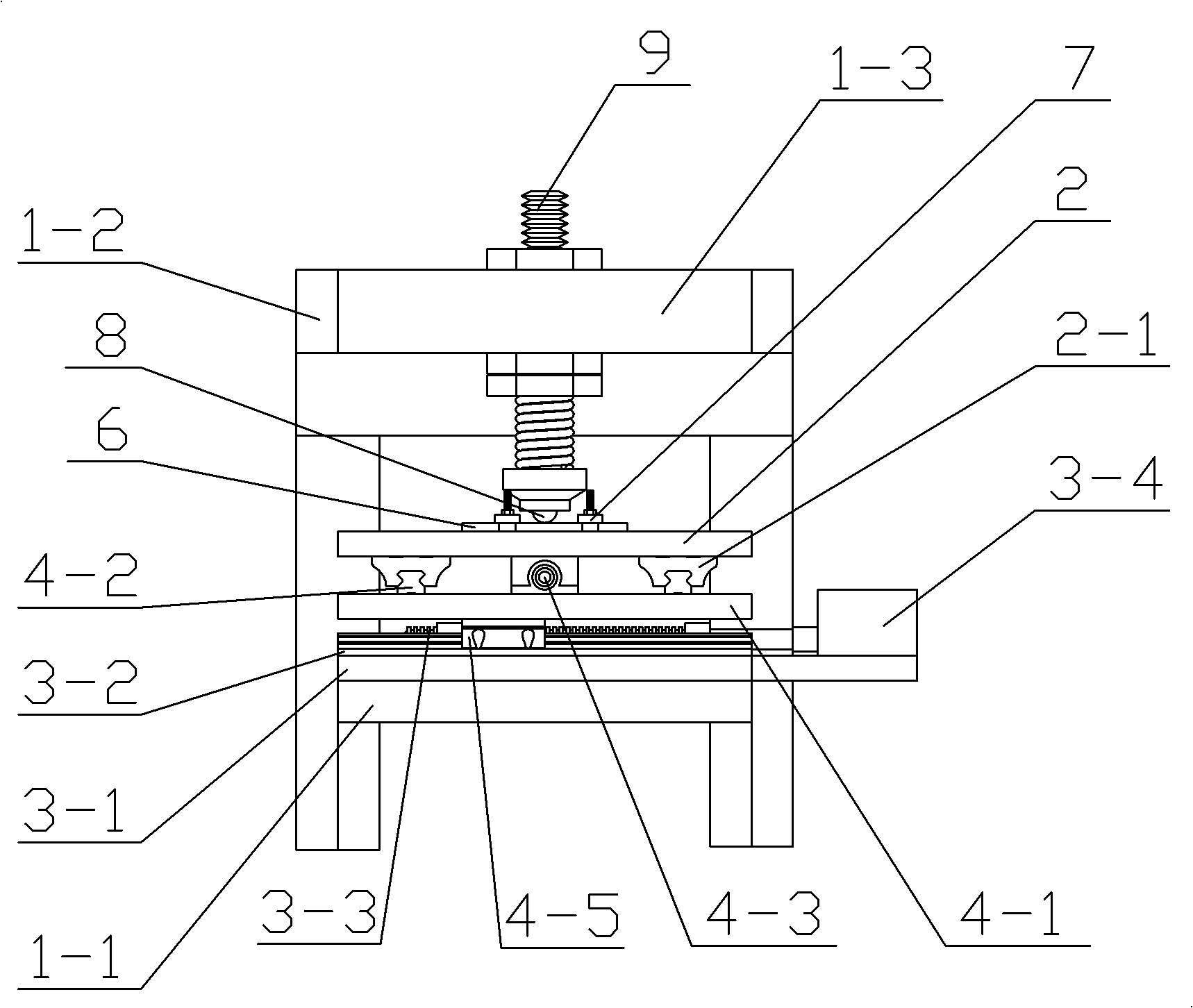

[0040] like figure 1 , figure 2 and image 3 As shown, the metal material surface nanometerization device of this embodiment includes a frame 1 and a working platform 2 horizontally arranged above the frame 1, and a device for controlling the working platform 2 along the Y direction is arranged between the frame 1 and the working platform 2. A moving Y-direction feed system 3 and an X-direction feed system 4 for controlling the movement of the working platform 2 in the X direction; the working platform 2 is provided with a groove 5 for fixing the metal material 6 on the working platform The clamp 7 on the 2 is installed on the working platform 2 through the groove 5, and the friction mechanism 8 for friction metal material 6 is arranged above the working platform 2; A load system 9 connected and used to apply pressure to the friction mechanism 8 .

[0041] like figure 1 , figure 2 and image 3 As shown, the frame 1 in this embodiment includes a base 1-1 and a gantry 1-...

Embodiment 2

[0048] like figure 1 , figure 2 and image 3 As shown, the metal material surface nanometerization device of this embodiment includes a frame 1 and a working platform 2 horizontally arranged above the frame 1, and a device for controlling the working platform 2 along the Y direction is arranged between the frame 1 and the working platform 2. A moving Y-direction feed system 3 and an X-direction feed system 4 for controlling the movement of the working platform 2 in the X direction; the working platform 2 is provided with a groove 5 for fixing the metal material 6 on the working platform The clamp 7 on the 2 is installed on the working platform 2 through the groove 5, and the friction mechanism 8 for friction metal material 6 is arranged above the working platform 2; A load system 9 connected and used to apply pressure to the friction mechanism 8 .

[0049] like figure 1 , figure 2 and image 3 As shown, the frame 1 in this embodiment includes a base 1-1 and a gantry 1-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com