Pump

a technology of pump and pump body, applied in the direction of pump control, positive displacement liquid engine, motor parameter, etc., can solve the problems of low pressure and irregular flow rate, inability to deal with corrosive reagents, irregular output flow rate, etc., and achieve constant level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

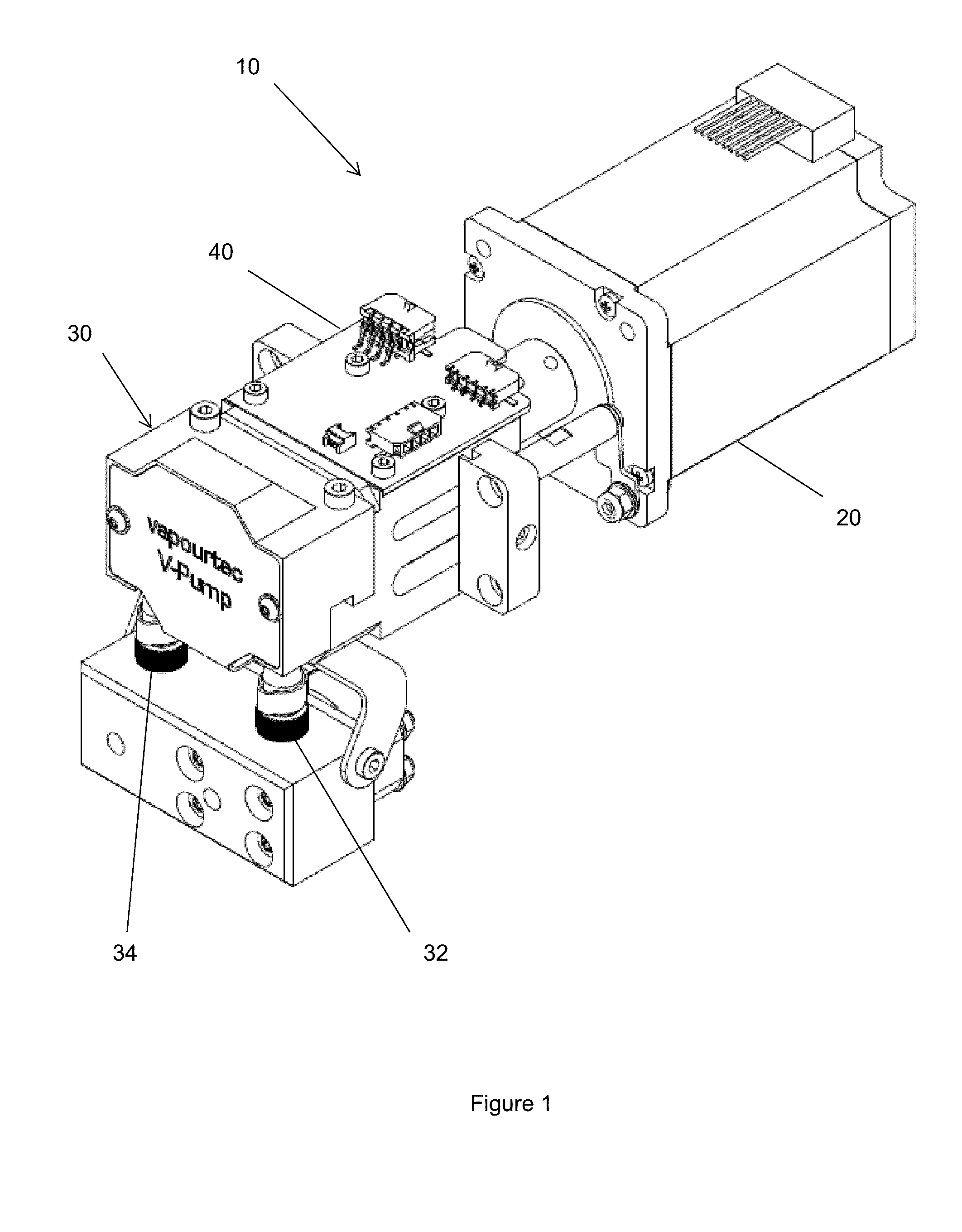

[0078]FIG. 1 shows a perspective view of a peristaltic pump 10 according to an embodiment of the present invention. The pump has a stepper motor 20, a pump unit 30 and circuit board 40. Further control circuitry and connections, discussed in more detail below, connect the circuit board 40 and the stepper motor 20 and control the operation of the pump 10.

[0079]The pump unit 30 is arranged to pump reagents from inlet 34 out through outlet 32. The inlet 34 is generally connected, in use, to a source of a reagent, such as a storage vat or bottle, or to the output of an earlier reaction system. The outlet 32 is generally connected, in use, to a reaction chamber for conducting flow chemistry. Suitable sources of reagents and reaction chambers are well known in the art and will not be described further here.

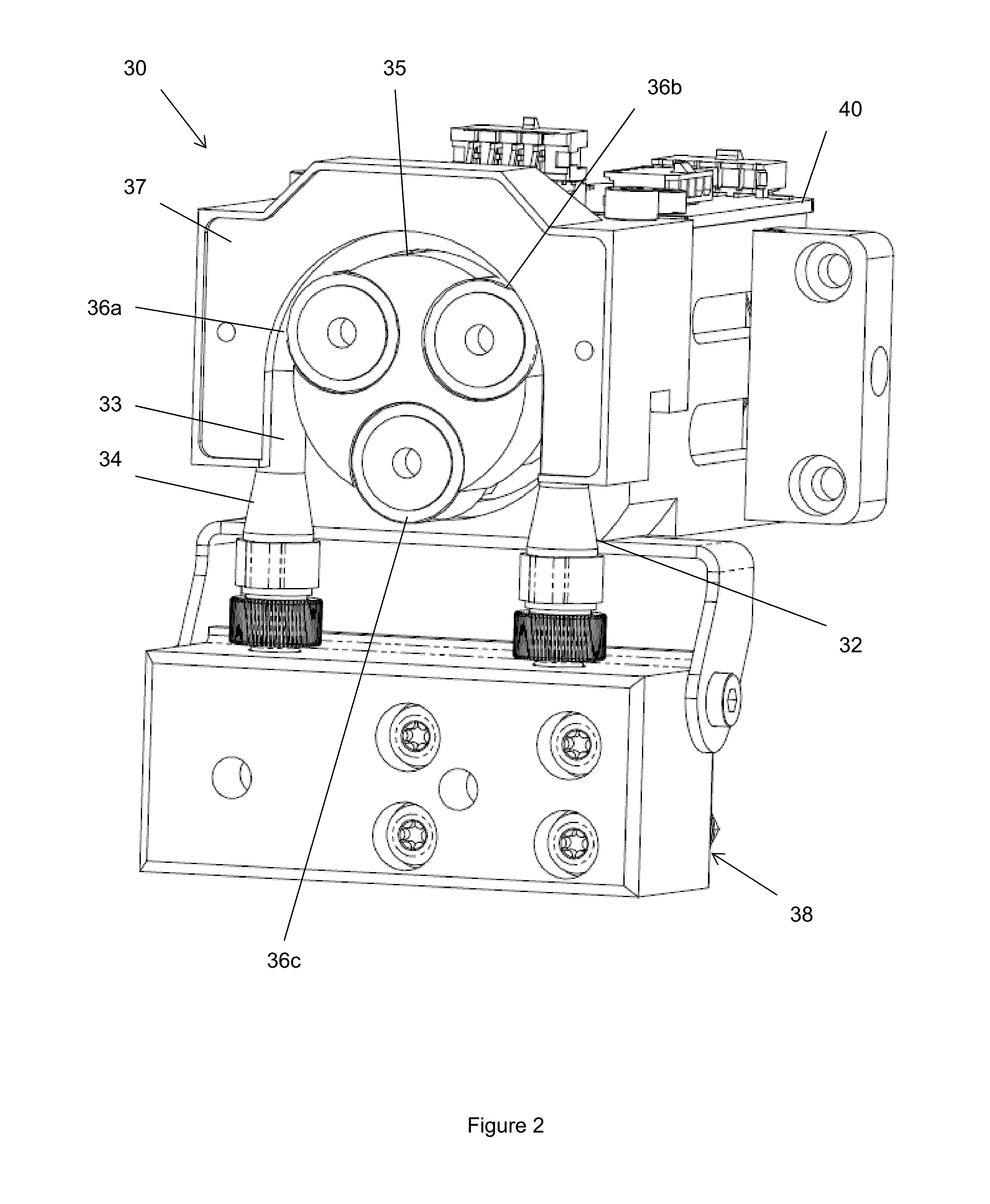

[0080]FIG. 2 shows the detail of the pump unit 30 with the front cover removed. The pump unit consists of a standard, albeit high quality and rugged, peristaltic pump configuration in w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com