Method for improving critical current for continuously preparing YBCO (Yttrium Barium Copper Oxide) strip

A critical current, strip technology, applied in metal material coating process, ion implantation plating, coating and other directions, can solve problems such as cubic texture deterioration, improve electrical properties, improve uniformity, improve target material The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

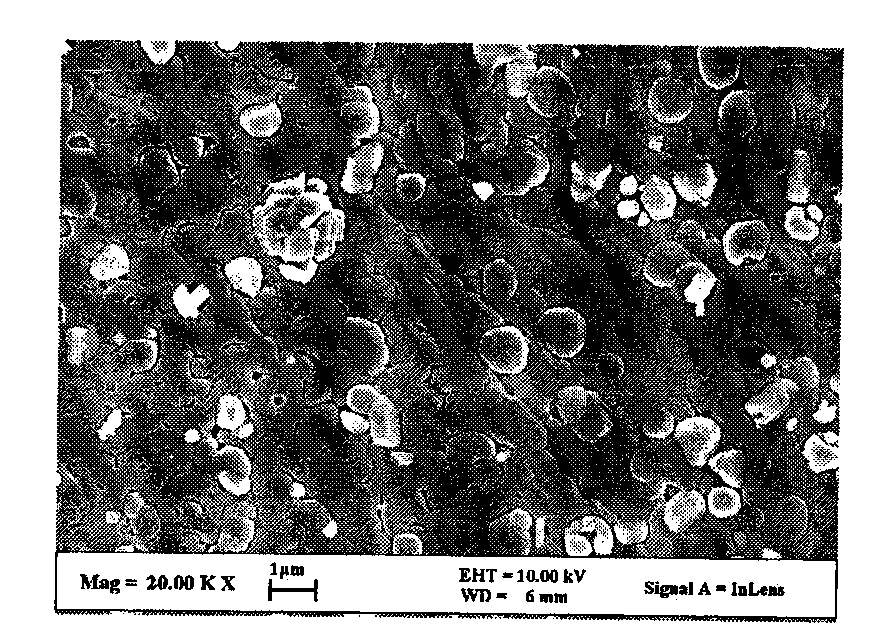

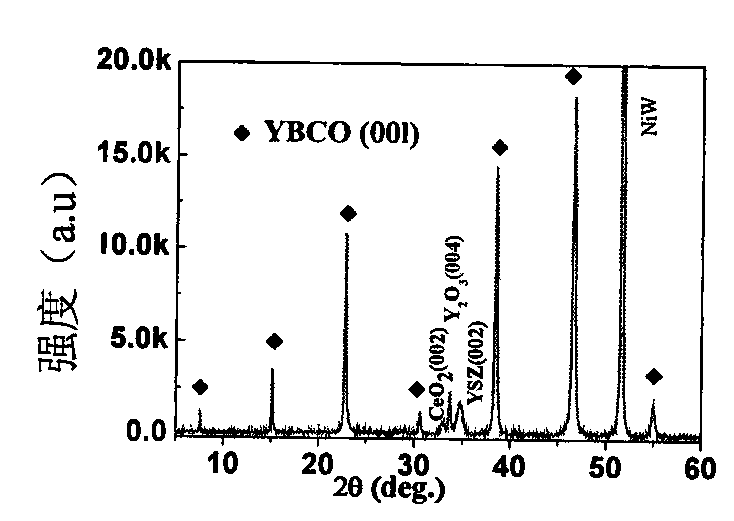

[0044] The YBCO superconducting layer is prepared by the laser method, the target material is a YBCO target of Φ50×5mm, and the target base distance (the distance between the target material and the metal base band) is about 40mm. The target is kept spinning during deposition.

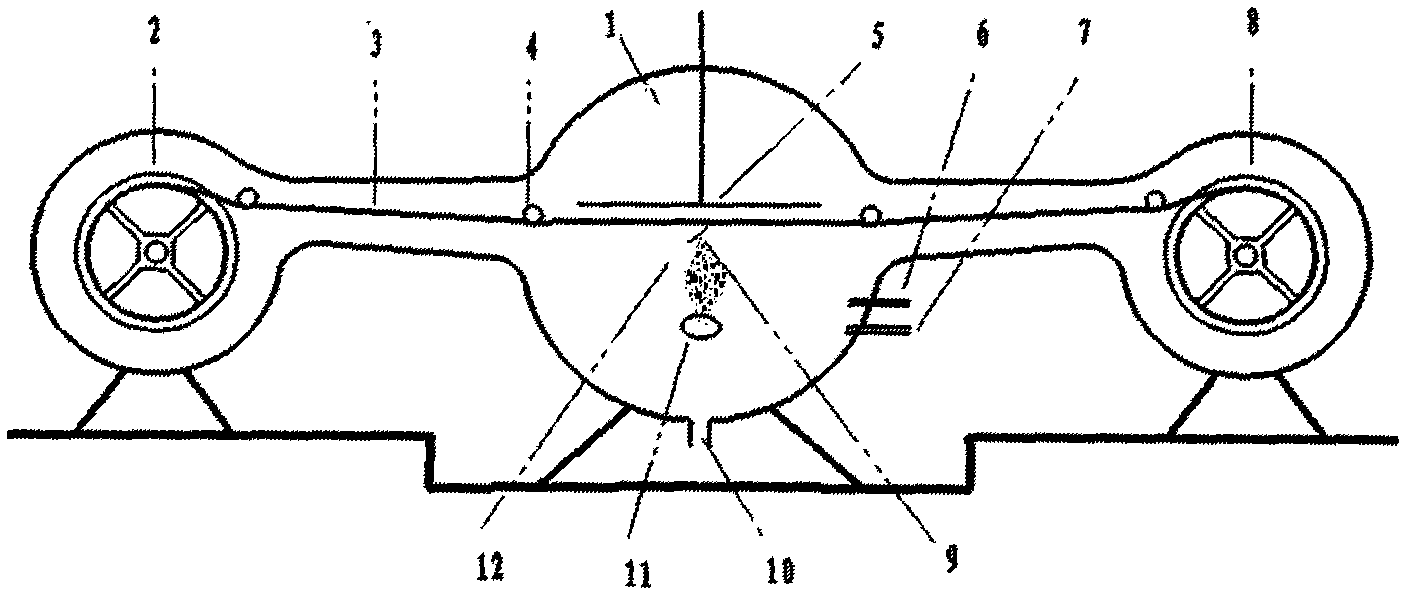

[0045] will carry CeO 2 / YSZ / Y 2 o 3 The NiW substrate of the isolation layer is pasted under the stainless steel guide belt, the size of the substrate is 3×10mm, and the stainless steel guide belt is installed between the left wheel 2 and the right wheel 8 . The left and right wheels are driven to rotate at a constant speed by the stepping motor, and the rotating speed is adjustable, so that the base belt can be driven to move at a constant speed at a constant speed.

[0046] Adjust the optical path of the laser so that the laser is focused on the target and directly below the baseband.

[0047] Close the cavity of the vacuum equipment, and evacuate to 2.5×10 -4 Pa, use the heating lamp 5 to heat...

specific Embodiment 2

[0053] The YBCO superconducting layer is prepared by laser method, the target material is a YBCO target of Φ50×5mm, and the target base distance (the distance between the target material and the metal base band) is about 50mm. The target is kept spinning during deposition.

[0054] will carry CeO 2 / YSZ / Y 2 o 3 The NiW baseband of the isolation layer is spot-welded on both ends of the stainless steel leader, the length of the baseband is 100mm, and the stainless steel leader is installed between the left wheel 2 and the right wheel 8. The left and right wheels are driven to rotate at a constant speed by the stepping motor, and the rotating speed is adjustable, so that the base belt can be driven to move at a constant speed at a constant speed.

[0055] Adjust the optical path of the laser so that the laser is focused on the target and directly below the baseband.

[0056] Close the cavity of the vacuum equipment, and evacuate to 2.5×10 -4 Pa, heat the temperature to 760°C...

specific Embodiment 3

[0067] The YBCO superconducting layer is prepared by the laser method, the target material is a YBCO target of Φ70×5mm, and the target base distance (the distance between the target material and the metal base band) is about 60 mm. The target is kept spinning during deposition.

[0068] will carry CeO 2 / YSZ / Y 2 o 3 The NiW baseband of the isolation layer is spot-welded on both ends of the stainless steel leader, the length of the baseband is 60mm, and the stainless steel leader is installed between the left wheel 2 and the right wheel 8. The left and right wheels are driven to rotate at a constant speed by the stepping motor, and the rotating speed is adjustable, so that the base belt can be driven to move at a constant speed at a constant speed.

[0069] Adjust the optical path of the laser so that the laser is focused on the target and directly below the baseband.

[0070] Close the cavity of the vacuum equipment, and evacuate to 2.5×10 -4Pa, heat the temperature to 77...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com