Method for preparing yttrium-barium-copper-oxygen super conductive-film sol-gel

A yttrium barium copper oxide and sol technology, applied in the field of microelectronics and materials, can solve the problems of difficulty in obtaining superconductivity of thin films, long preparation process cycle, long time consumption, etc., and achieves shortened heat treatment time, easy adjustment of components, and simple preparation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation method of the above-mentioned yttrium barium copper oxide high temperature superconducting film sol comprises the following steps:

[0025] 1) Dissolve yttrium acetate in methanol, add a small amount of diethylenetriamine and benzoylacetone, so that yttrium acetate:methanol:diethylenetriamine:benzoylacetone=1:(10~40):(1~5): (0~2), form solution A after stirring;

[0026] 2) Dissolve barium acetate in a mixed solution containing water and trifluoroacetic acid, so that barium acetate: water: trifluoroacetic acid = 1: (10-80): (2-5), after stirring and dissolving, after 65 ° C ~ Dry at 85°C, and dissolve the resulting product in methanol solution so that the molar ratio Ba 2+ : Methanol=1: (10~40), obtain solution B;

[0027] 3) Dissolve copper acetate in methanol, add a small amount of acrylic acid and phenylacetone, so that copper acetate: methanol: acrylic acid: benzoylacetone = 1: (10~40): (2~10): (0.1~2) , forming solution C after slight heating and...

Embodiment 1

[0036] Dissolve yttrium acetate in methanol, add diethylenetriamine so that the molar ratio of each component is: yttrium acetate:methanol:diethylenetriamine=1:27:1.5, and form solution A after stirring and clarification.

[0037] Dissolve barium acetate in a mixed liquid containing water and trifluoroacetic acid so that barium acetate: water: trifluoroacetic acid = 1:40:3. After stirring and dissolving, the substance obtained after drying at 80°C was redissolved in methanol solution so that the molar ratio Ba 2+ :methanol=1:20, and solution B was obtained after stirring and clarification.

[0038] Dissolve copper acetate in methanol, add a small amount of acrylic acid and phenylacetone to make copper acetate: methanol: acrylic acid: benzoylacetone = 1:22:2:0.2, and form solution C after slight heating and stirring.

[0039] Mix the above solutions A, B, and C, and stir, so that Y 3+ : Ba 2+ : Cu 2+ =1:2:3.2, forming the required sol.

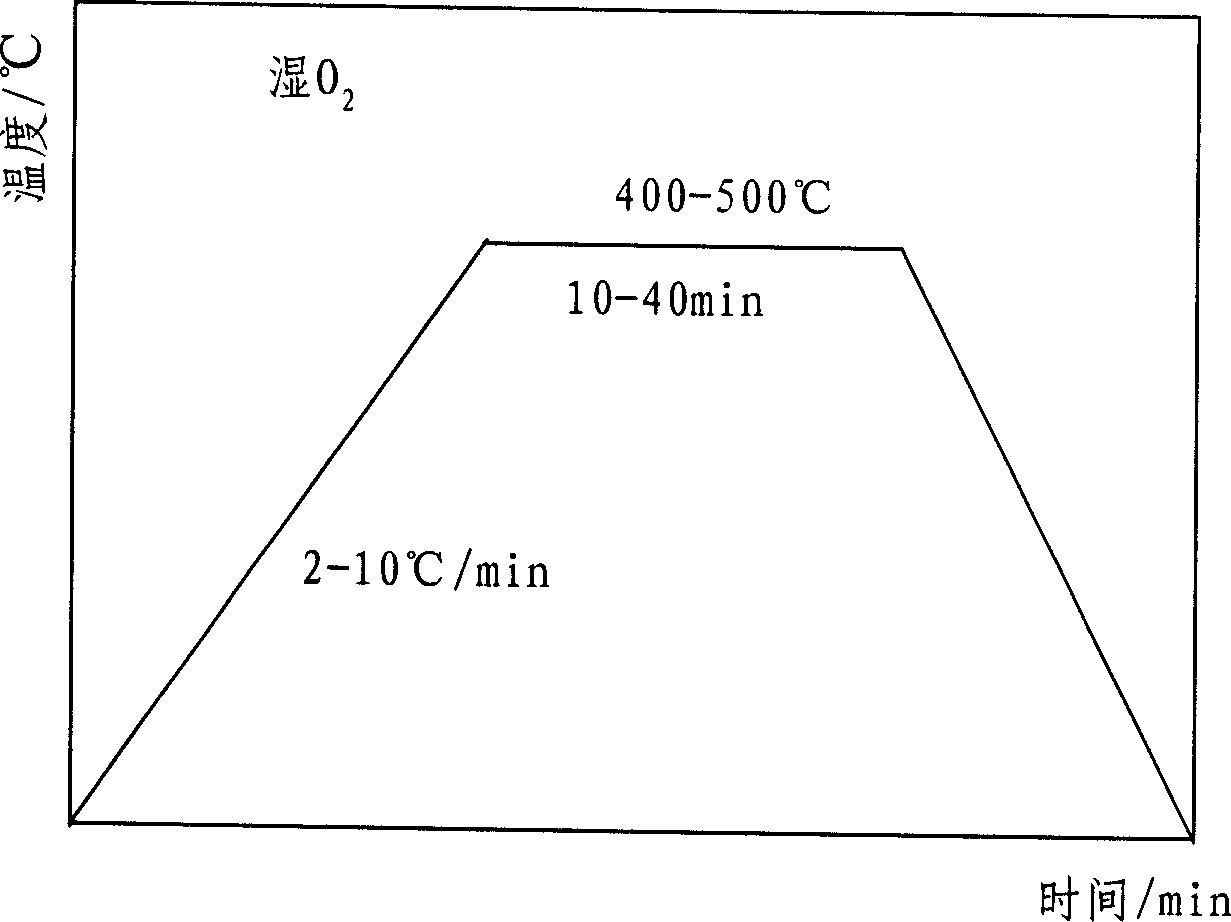

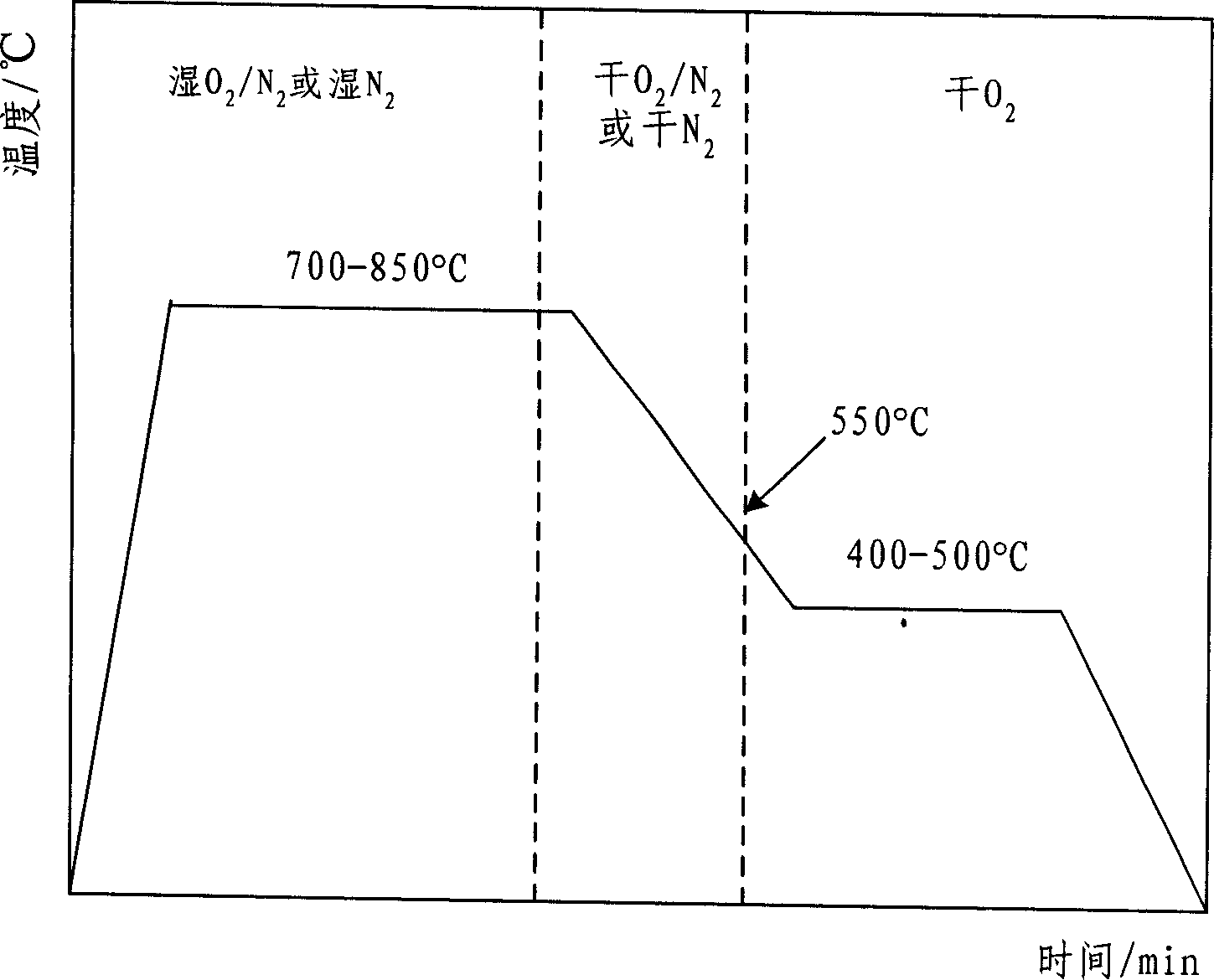

[0040] Using the sol, a layer of ge...

Embodiment 2

[0042] Dissolve yttrium acetate in methanol, add diethylenetriamine and phenylacetone, so that the molar ratio of each component is: yttrium acetate: methanol: diethylenetriamine: phenylacetone = 1: 25: 1.5: 0.2, after Solution A was formed after stirring to clarify.

[0043] Dissolve barium acetate in a mixed solution of water and trifluoroacetic acid so that barium acetate: water: trifluoroacetic acid = 1:40:3, stir and dissolve, and dry at 75°C to form a viscous glassy substance. and redissolved in methanol solution such that the molar ratio Ba 2+ :methanol=1:16, and solution B was obtained after stirring and clarification.

[0044] Take copper acetate as raw material, dissolve it in methanol, add a small amount of propionic acid and benzoylacetone to make copper acetate: methanol: propionic acid = 1:25:3:0.2, and form solution C after slight heating and stirring.

[0045] Mix the above three solutions A, B, and C and stir, so that Y 3+ : Ba 2+ : Cu 2+ =1:2:4, forming ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com