Method for preparing Yt-Ba-Cu-O high-temperature superconductive film fine-pattern

A technology of high-temperature superconducting thin film and yttrium-barium-copper-oxygen is applied in the usage of superconducting elements, manufacturing/processing of superconducting devices, superconducting devices, etc. It can solve problems such as difficult corrosion and high-quality micro-graphics, etc. To achieve the effect of regular graphics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The preparation method of the sol for the above-mentioned yttrium barium copper oxide high temperature superconducting film comprises the following steps:

[0020] 1) Dissolve yttrium acetate in methanol, add a small amount of diethylenetriamine and benzoylacetone, so that yttrium acetate:methanol:diethylenetriamine:benzoylacetone=1:(10~40):(1~5): (0~2), form solution A after stirring;

[0021] 2) Dissolve barium acetate in a mixed solution containing water and trifluoroacetic acid, so that barium acetate: water: trifluoroacetic acid = 1: (10-80): (2-5), after stirring and dissolving, after 65 ° C ~ Dry at 85°C, and dissolve the resulting product in methanol solution so that the molar ratio Ba 2+ : Methanol=1: (10~40), obtain solution B;

[0022] 3) Dissolve copper acetate in methanol, add a small amount of acrylic acid and phenylacetone, so that copper acetate: methanol: acrylic acid: benzoylacetone = 1: (10~40): (2~10): (0.1~2) , forming solution C after slight hea...

Embodiment 1

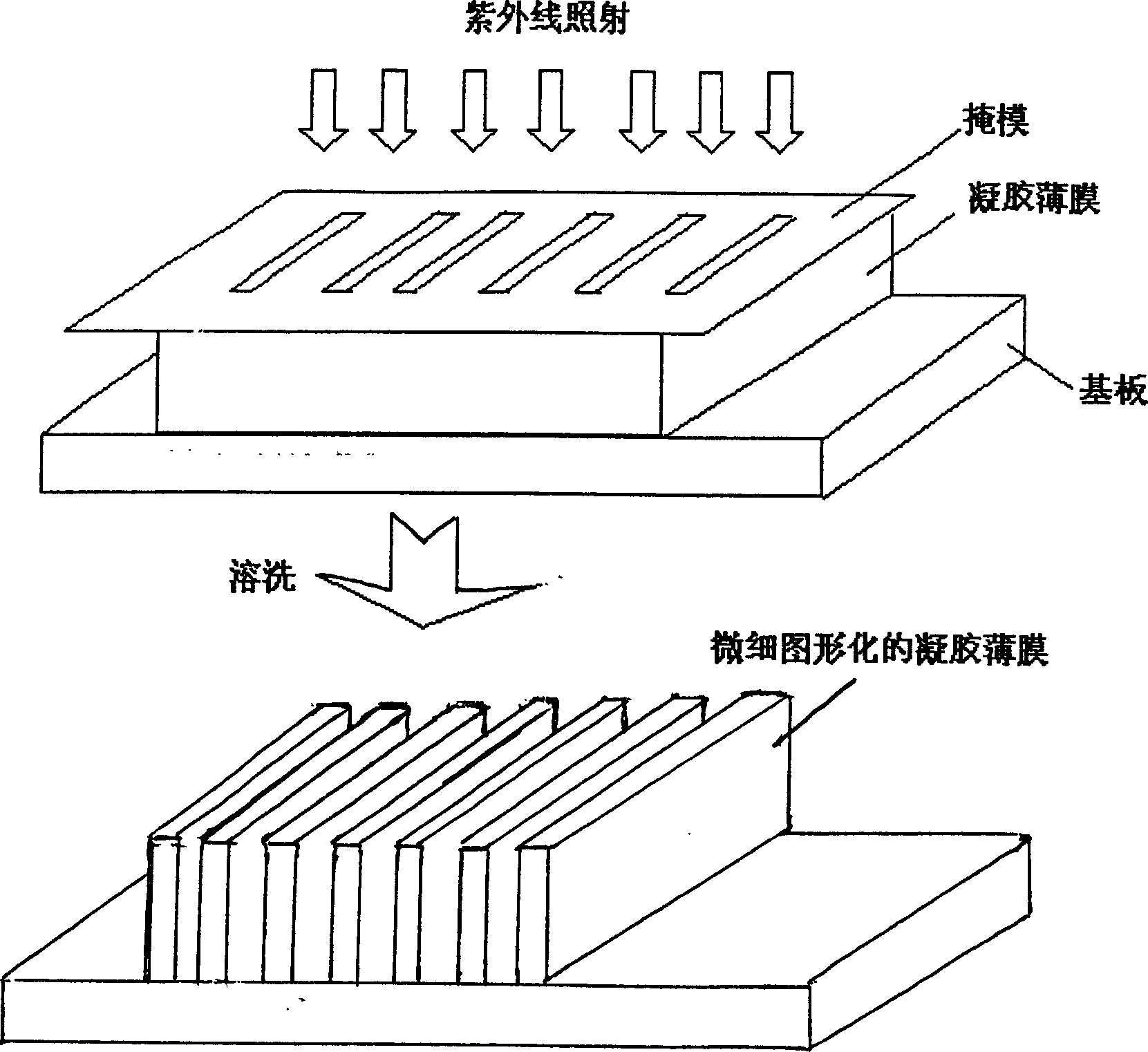

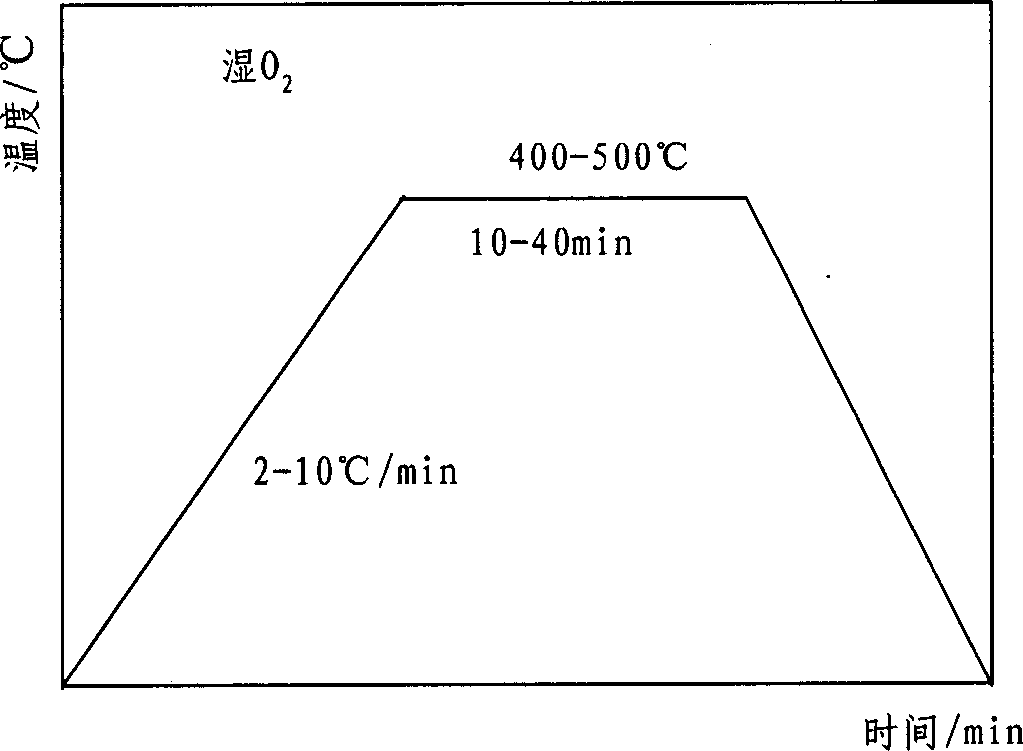

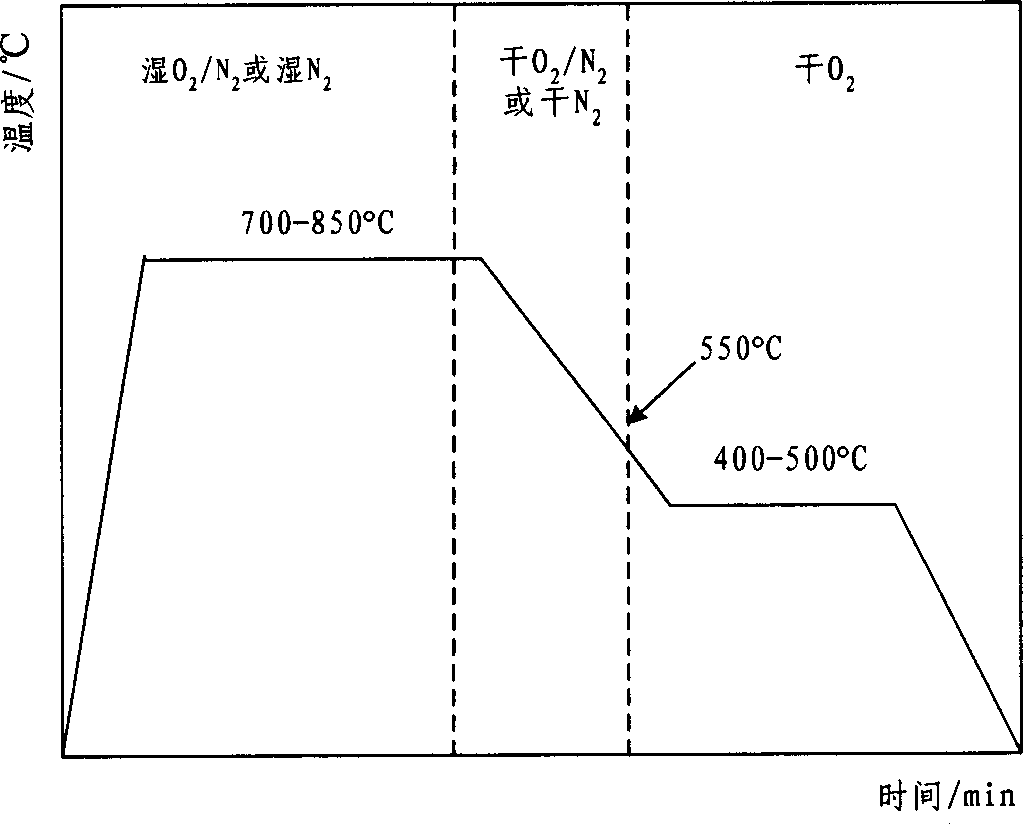

[0030] Using yttrium-barium-copper-oxygen high-temperature superconducting sol, coat a layer of gel film on the single crystal LAO (001) substrate at room temperature, and dry the obtained gel film at 90°C , irradiated under ultraviolet light for 8 minutes through a mask, and then washed by methanol, the fine pattern of the gel film can be obtained. Subsequently, after the film was kept at 150-200°C for 10 minutes, the water vapor pressure was 4% O 2 In the atmosphere, the temperature was raised to 450°C at a rate of 5°C / min, and kept for 10 minutes. Subsequently, the obtained inorganic membrane was treated with high-purity N 2 In the gas, the temperature is rapidly raised to 780 ° C, and the temperature is kept at 4% water vapor for 2 hours. Subsequently, the atmosphere was switched to dry nitrogen. After continuing to keep warm for 30 minutes, with the furnace cooling down to 550°C, switch the gas to dry O 2 , and kept at 450°C for 3 hours, and finally cooled down to roo...

Embodiment 2

[0032] Using the prepared yttrium-barium-copper-oxygen high-temperature superconducting sol, through the pulling method, the (010)-oriented LaAlO 3 A layer of gel film is coated on the single crystal substrate, and the obtained gel film is dried at 100°C, irradiated with ultraviolet light through a mask for 10 minutes, and then washed with methanol to obtain a fine pattern of the gel film. Under the protection of oxygen, the gel film was incubated at 200 °C for 10 minutes, and then heated in O with 4% water vapor content. 2In the atmosphere, the temperature was raised to 400°C at a heating rate of 10°C / min, and kept for 10 minutes, and then taken out after being cooled in the furnace. Subsequently, the obtained inorganic film was exposed to 1% oxygen in N 2 / O 2 In the mixed atmosphere, rapidly raise the temperature to 750°C, switch to the same gas containing 4% water vapor, and keep it warm for 2 hours. After the hold, switch the gas to dry N with 1% oxygen 2 / O 2 Mixed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Critical transition temperature | aaaaa | aaaaa |

| Superconducting transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com