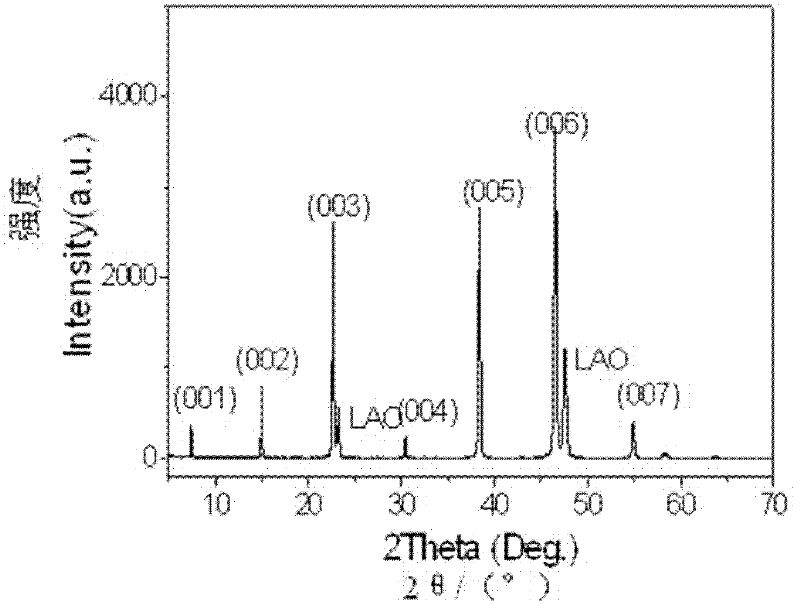

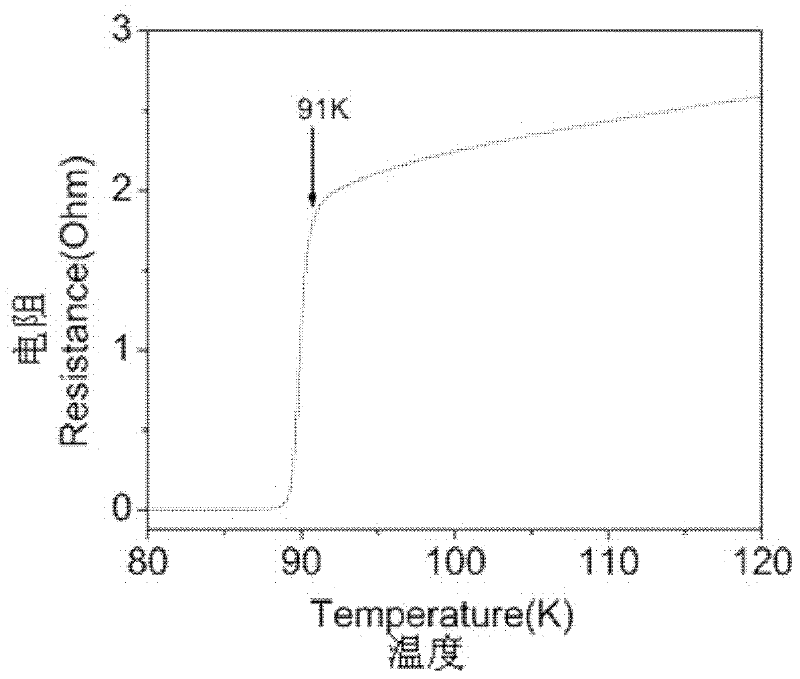

Preparation method of high temperature superconductive film adopting modified low fluoride solution method

A technology of high-temperature superconducting thin film and solution method, which is applied in the field of high-temperature superconducting microelectronic materials and devices and the field of coating conductor preparation, which can solve the problems of easy cracking of thin films and loss of copper ions, etc. Avoid the effect of easy cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] 2) Preparation and drying of gel film:

[0039] Using low fluoride yttrium barium copper oxygen solution as the precursor solution, combined with dipping and pulling method or spin coating method, on lanthanum aluminate or strontium titanate single crystal substrate, or NiW alloy strip with buffer layer, prepared The yttrium barium copper oxide gel film, and then the obtained gel film is dried in the air at a temperature of 80-100°C for 5-20 minutes to obtain a yttrium barium copper oxide dry film;

[0040] 3) Film pretreatment:

[0041] Put the obtained yttrium-barium-copper-oxygen dry film into a quartz tube sintering furnace, and first pass moist O with a water vapor pressure of 4~5kPa 2 Then increase the temperature in the furnace to 200℃ at any rate, and then increase the temperature in the furnace to 400~500℃ at a rate of 2~20℃ / min, and keep it for 5~15min; finally, it will be cooled to Room temperature, and stop passing in moisture O 2 In the above pretreatment process...

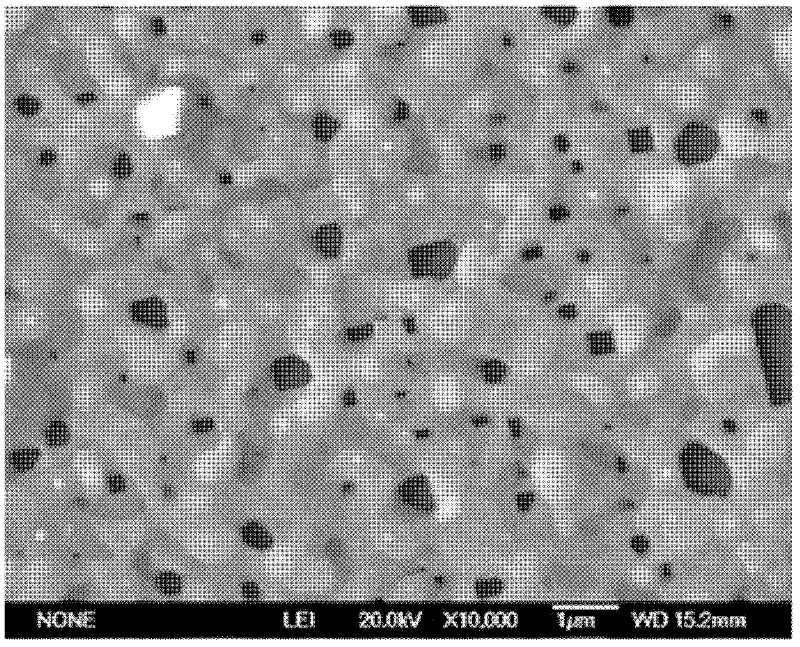

Embodiment 1

[0047] This embodiment provides a modified low-fluorine solution method for preparing a high-temperature superconducting film, which includes the following steps:

[0048] 1) Preparation of low fluorine yttrium barium copper oxygen solution;

[0049] 1.1 Dissolve yttrium oxide in trifluoroacetic acid containing water (in order to prevent the volatilization of trifluoroacetic acid, add water to trifluoroacetic acid, the volume ratio of trifluoroacetic acid to water is 1:1), and heat it at 40°C After stirring and dissolving, drying at 70℃ to obtain white solid A, then adding methanol to white solid A for dilution, stirring and dissolving to obtain solution A; wherein the molar ratio of yttrium oxide: trifluoroacetic acid: methanol is 0.5:5 : 20;

[0050] 1.2 Dissolve barium acetate in a mixed solution of lactic acid and methanol, control the molar ratio of barium acetate: lactic acid: methanol to 1:6:15, stir and dissolve to obtain solution B;

[0051] 1.3 First dissolve copper acetate...

Embodiment 2

[0061] This embodiment provides a modified low-fluorine solution method for preparing a high-temperature superconducting film, which includes the following steps:

[0062] 1) Preparation of low fluorine yttrium barium copper oxygen solution;

[0063] 1.1 Dissolve yttrium acetate in trifluoroacetic acid containing water (in order to prevent the volatilization of trifluoroacetic acid, add water to trifluoroacetic acid, the volume ratio of trifluoroacetic acid to water is 1:2), and heat at 50℃ After stirring and dissolving, after drying at 90°C, a white solid A is obtained. Then acrylic acid is added to the white solid A for dilution. After stirring and dissolving, a solution A is obtained; the molar ratio of yttrium acetate:trifluoroacetic acid:acrylic acid is 1:3: 30;

[0064] 1.2 Dissolve barium acetate in a mixed solution of acrylic acid (complexing agent B) and methanol (solution B), control the molar ratio of barium acetate: acrylic acid: methanol to 1:10:20, stir and dissolve to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com