Process for applying polymer to individual conductors and HTS composite produced from the individual conductors

A technology of superconductors and composites, which is applied in the usage of superconductor elements, cable/conductor manufacturing, superconducting devices, etc., and can solve problems such as increased thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

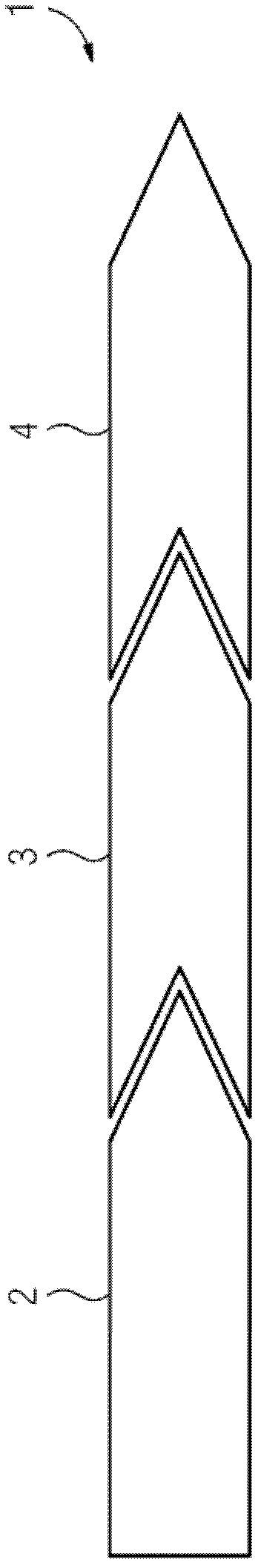

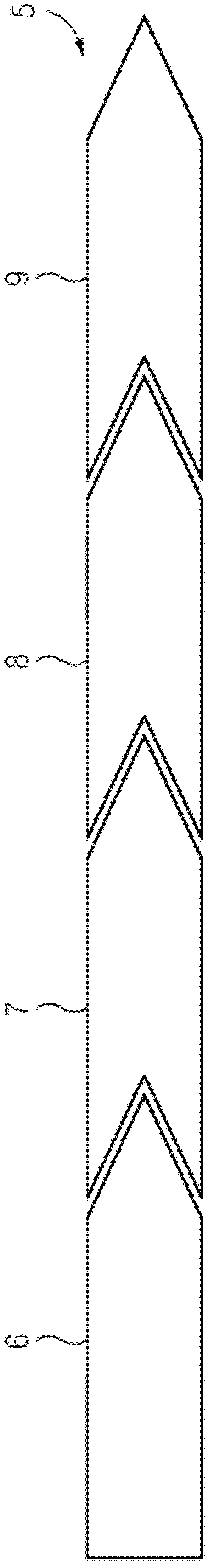

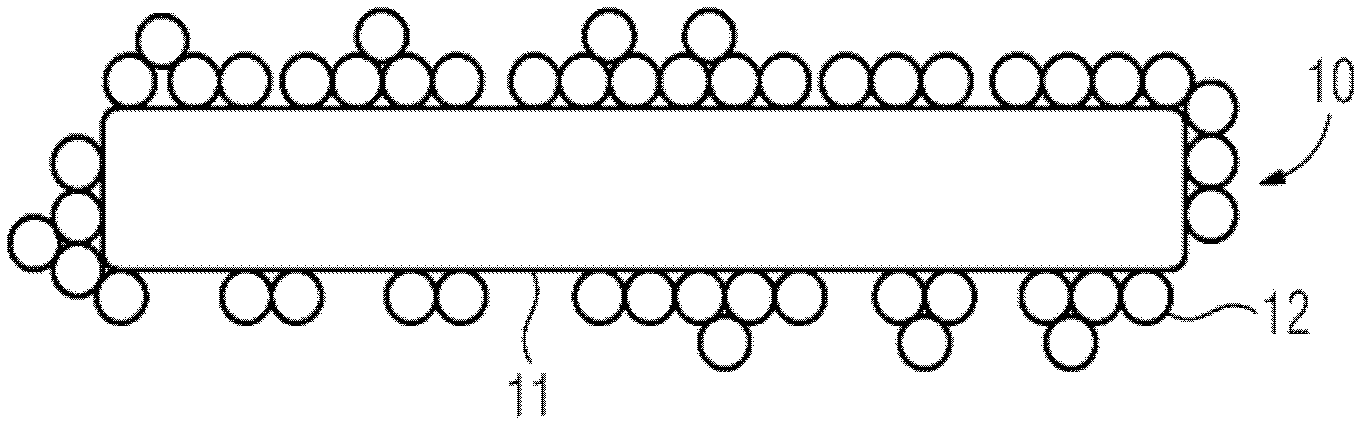

[0037] figure 1 Process flow 1 is shown for particle coating of individual conductors 10 with "dry" plastic particles 12 . exist image 3 and 4 Correspondingly, the individual conductors 10 after the respective steps are shown in . The individual conductor 10 comprises a carrier 11 with at least one superconducting layer. The carrier consists, for example, of steel. The superconducting layer can consist, for example, of a YBCO material and be designed as a thin coating on one or more sides of the carrier 11 . In order to improve the adhesion of the superconducting layer, one or more buffer layers can be arranged between the surface of the carrier 11 and the superconducting layer lying thereon.

[0038] Particles 12 coated with plastic for a single conductor 10, according to figure 1 In the method shown, the first step is to apply an electrostatic coating or a powder coating to the individual conductors 10 . Next, the coated individual conductors 10 are subjected to heat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com