Oxide superconductor and its manufacturing method

A technology of superconducting conductor and manufacturing method, which is applied in the manufacture/processing of superconductor device, cable/conductor manufacture, superconducting/high-conducting conductor, etc., can solve the problem of high manufacturing cost, insufficient superconducting characteristics, continuous oxide superconductor layer, etc. problems such as sexual damage, and achieve the effect of low cost and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

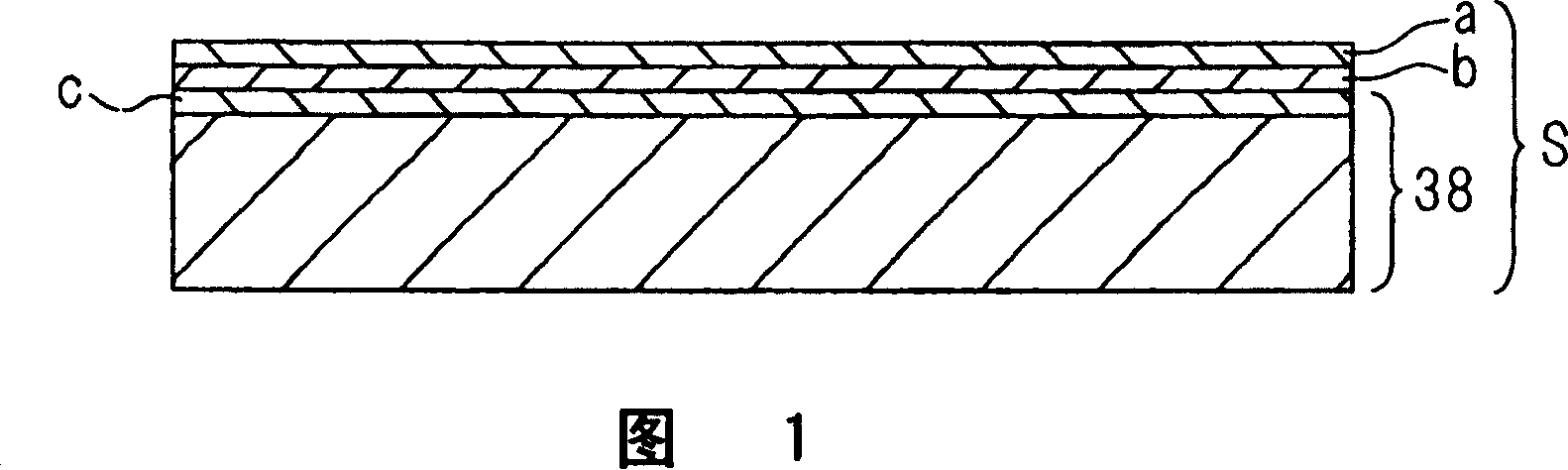

[0079] Fig. 1 is a schematic cross-sectional structure of an oxide superconducting conductor according to a first embodiment of the present invention. The oxide superconducting conductor S shown in the figure is a substrate 38 made of Ag and an oxide superconductor layer b formed on the substrate 38 and an oxide superconductor layer b formed on the oxide superconductor layer b. The stabilization layer a is laminated in order. Therefore, the surface layer portion of the substrate 38 is formed with a diffusion layer c of a layer in which Cu is diffused into Ag constituting the substrate 38.

[0080] The base material 38 may be elongated, but it is particularly preferable to use an orientation tape of Ag that produces a rolled texture, and it may be provided with a diffusion layer in which Cu is diffused into the orientation tape. Alternatively, it may be provided with an Ag film having a rolling texture on one or both surfaces of a strip-shaped substrate such as a metal belt. As the...

no. 2 Embodiment approach

[0087] [Base material for oxide superconducting conductors]

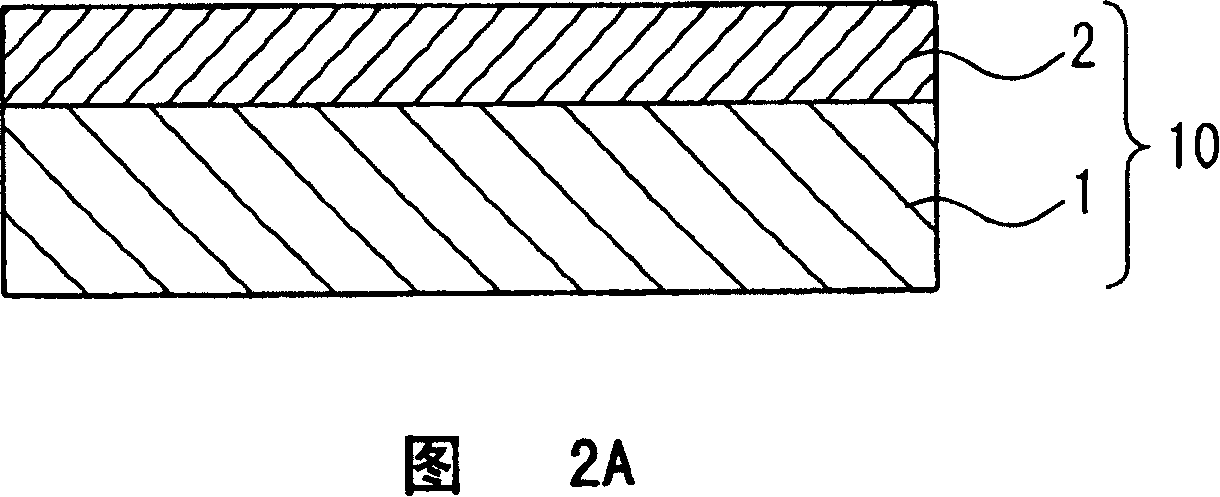

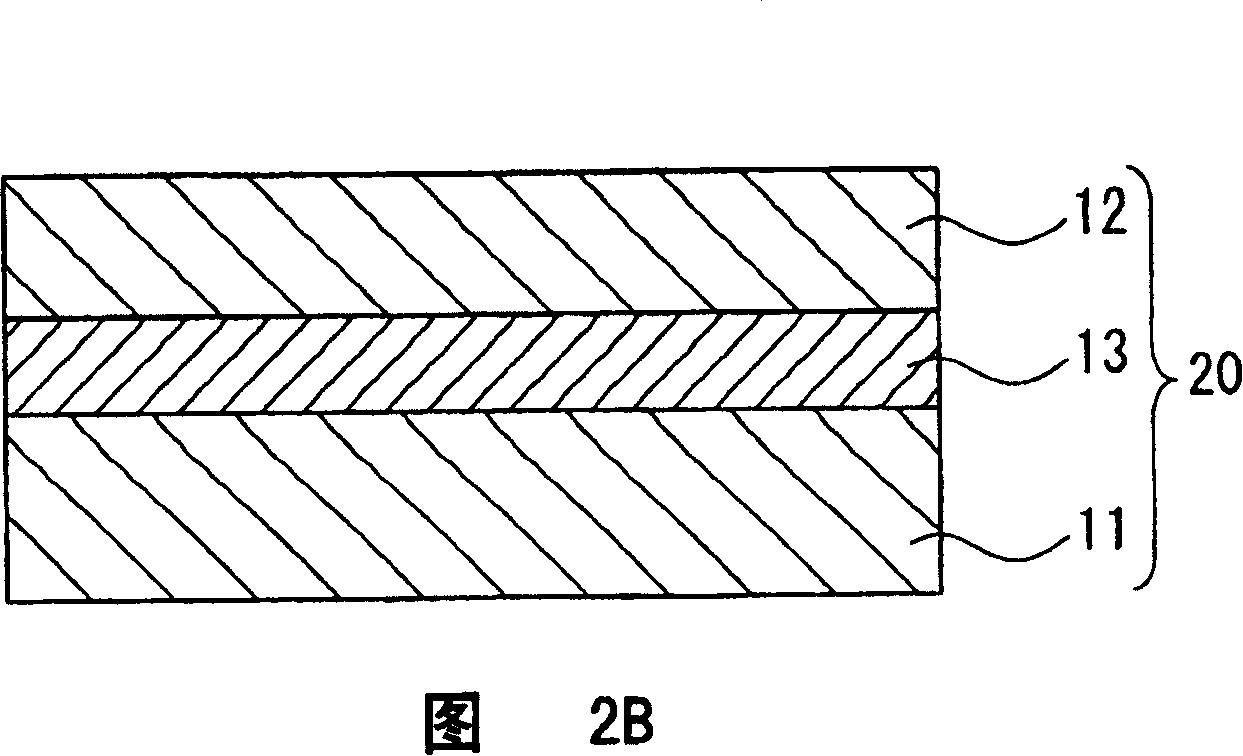

[0088] 2A is a schematic diagram of a cross-sectional structure example of one embodiment of a substrate for an oxide superconducting conductor of the present invention, and FIG. 2B is a schematic diagram of another embodiment of a substrate for an oxide superconducting conductor of the present invention, and FIG. The conductive substrate 10 is composed of a metal base material 1 made of a high-strength metal material and an Ag foil (Ag layer) 2 attached to the metal base material 1. The oxide superconducting conductor substrate 20 shown in FIG. 2B is composed of a metal base material 11 and a barrier layer 13 formed on the metal base material 11 and an Ag foil (Ag layer) 12 pasted on the barrier layer 13 constitute. 2A and 2B only show the cross-sectional structure of the oxide superconducting conductor, but it is actually a strip extending in a direction perpendicular to the paper surface.

[0089] The metal base mate...

no. 3 Embodiment approach

[0106] 4 is a schematic cross-sectional structure of an oxide superconducting conductor according to the third embodiment of the present invention. FIG. 4A is an example of the structure when an Ag substrate is used, and FIG. 4B is a structure when an Ag layer is formed on a metal base material example.

[0107] The oxide superconducting conductor shown in FIG. 4A is provided with a base material 21 made of Ag and a first oxide superconductor layer 22a, a second oxide superconductor layer 22b, The third oxide superconductor layer 22c is formed. Therefore, the first oxide superconductor layer 22a has a higher Cu content than the other oxide superconductor layers 22b and 22c.

[0108] The base material 21 shown in FIG. 4A may be elongated, but it is particularly preferable to use an orientation band of Ag that produces a rolled texture, or it may be provided with a diffusion layer in which Cu is diffused in the orientation band. Or it may be provided with an Ag film having a rolled ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com