Low-temperature fast powder sintering method for superconductive MgB2 nano particle

A nanoparticle and sintering method technology, applied in the field of superconductivity, can solve the problems of time-consuming Mg powder, oxidation, etc., and achieve the effects of uniform particle size, simple preparation method, and obvious superconductivity characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

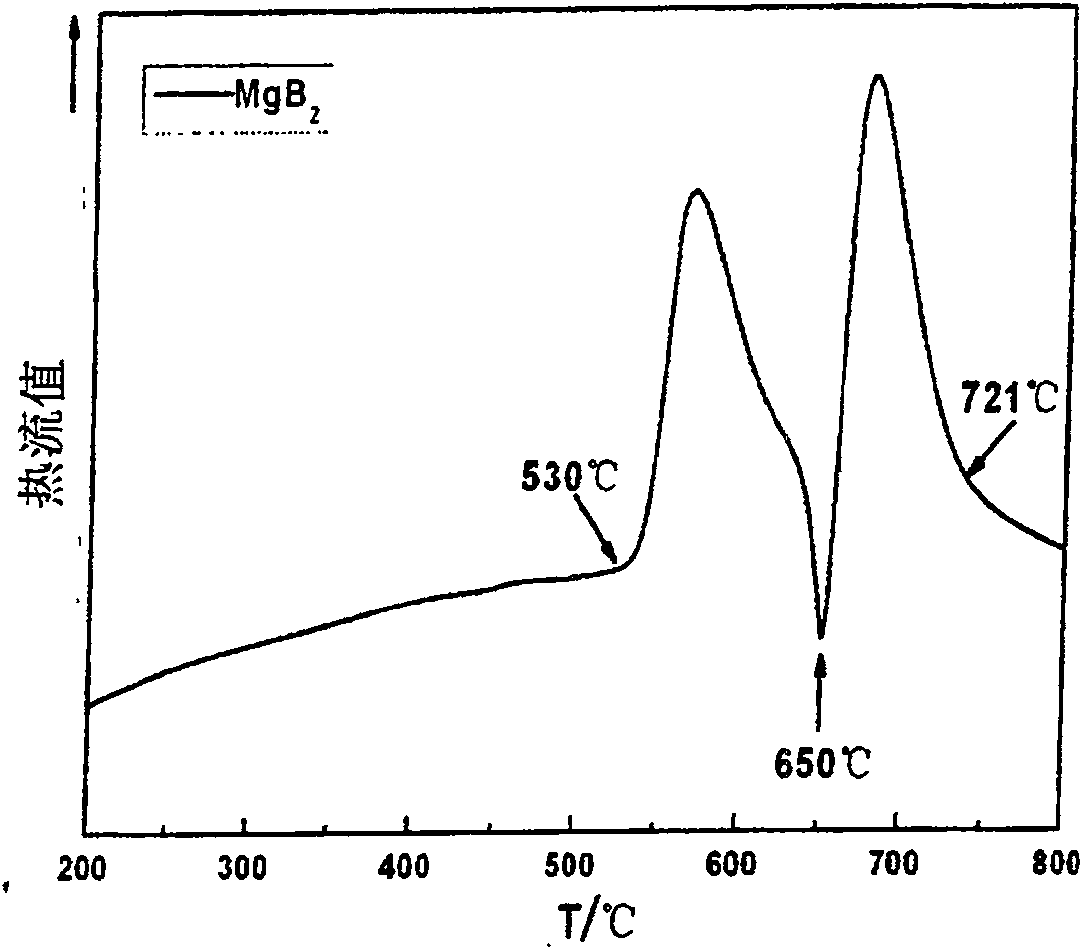

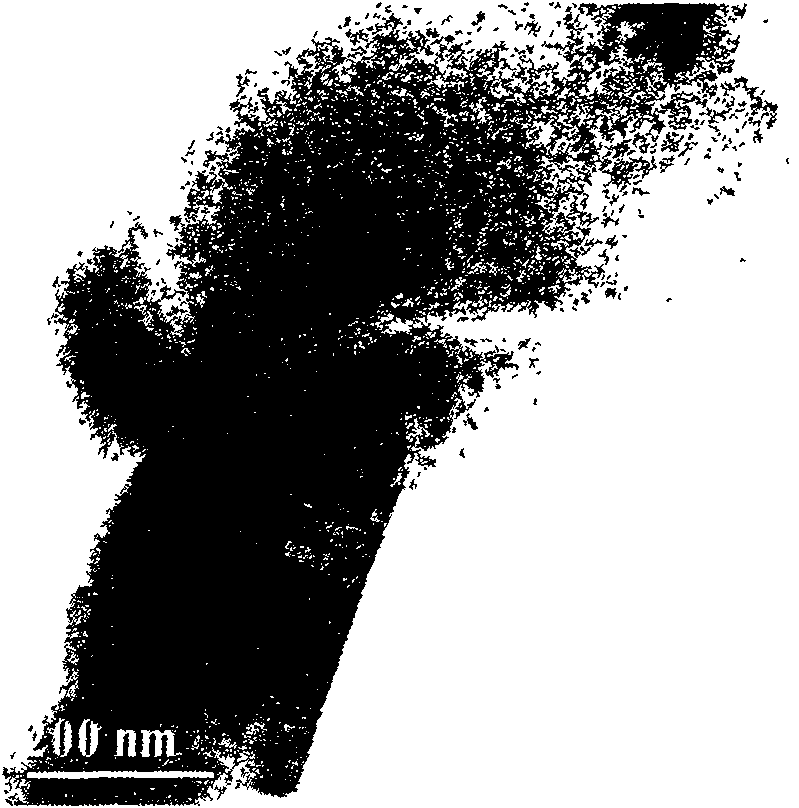

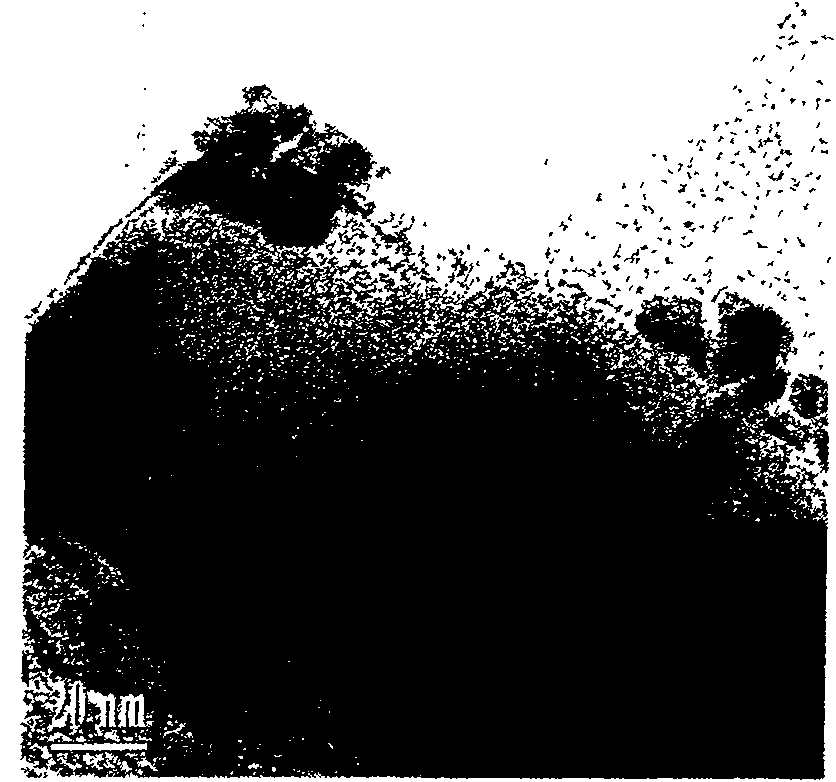

[0022] A superconducting MgB 2 The low-temperature rapid powder sintering method of nanoparticles is composed of the following steps: magnesium powder (purity 99.5%) and amorphous boron powder (purity 99%) are mixed according to the atomic ratio of Mg: B = 1: 2, and in agate grinding Grind it in a bowl for 1 hour to make it evenly mixed, and then press it under a pressure of 5Mpa to form a cylinder of φ4×2mm, and put the pressed sample into a high-temperature differential scanning calorimeter (NETZSCH DSC 404C Peganus) In the process, argon gas is introduced, and then the temperature program is set as follows: the heating rate is 20K / min, rising to 994K, and directly cooling down to room temperature (25°C) at a cooling rate of 40K / min, that is, a superconducting MgB 2 nanoparticles. Determine the phase composition and crystal morphology in the sample by various detection methods.

Embodiment 2

[0024] A superconducting MgB 2 The low-temperature rapid powder sintering method of nanoparticles is composed of the following steps: magnesium powder (purity 99.5%) and amorphous boron powder (purity 99%) are mixed according to the atomic ratio of Mg: B=1.5: 2, and in agate grinding Grind it in a bowl for 1 hour to make it evenly mixed, and then press it under a pressure of 5Mpa to form a cylinder of φ4×2mm, and put the pressed sample into a high-temperature differential scanning calorimeter (NETZSCH DSC 404C Peganus) In the process, argon is introduced, and then the temperature program is set as follows: the heating rate is 20K / min, rising to 994K, and directly cooling down to room temperature (30°C) at a cooling rate of 40K / min, by changing the atomic ratio of Mg and B. Excess Magnesium Effects on MgB 2The effect of nanoparticle formation and changes in the growth pattern of nanoparticles in the melt.

Embodiment 3

[0026] A superconducting MgB 2 The low-temperature rapid powder sintering method of nanoparticles is composed of the following steps: magnesium powder (purity 99.5%) and amorphous boron powder (purity 99%) are mixed according to the atomic ratio of Mg: B = 1: 2, and in agate grinding Grind in a bowl for 1 hour to make it evenly mixed, and then press it under a pressure of 5Mpa to form a cylinder of φ4×2mm, and put the pressed sample into a high-temperature differential scanning calorimeter (NETZSCH DSC 404C Peganus) In the middle, argon gas is introduced, and then the temperature program is set as follows: the heating rate is 40K / min, rises to 994K, and directly drops to room temperature (20°C) at a cooling rate of 40K / min, and the speed is observed by changing the heating rate. For MgB 2 Effects of nanoparticle formation and changes in morphology.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com