Method for the production of superconducting electrical conductor

A technology of superconductivity and electric conductor, which is applied in the direction of manufacturing/processing of superconducting/high-conducting conductors, superconducting devices, superconducting devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

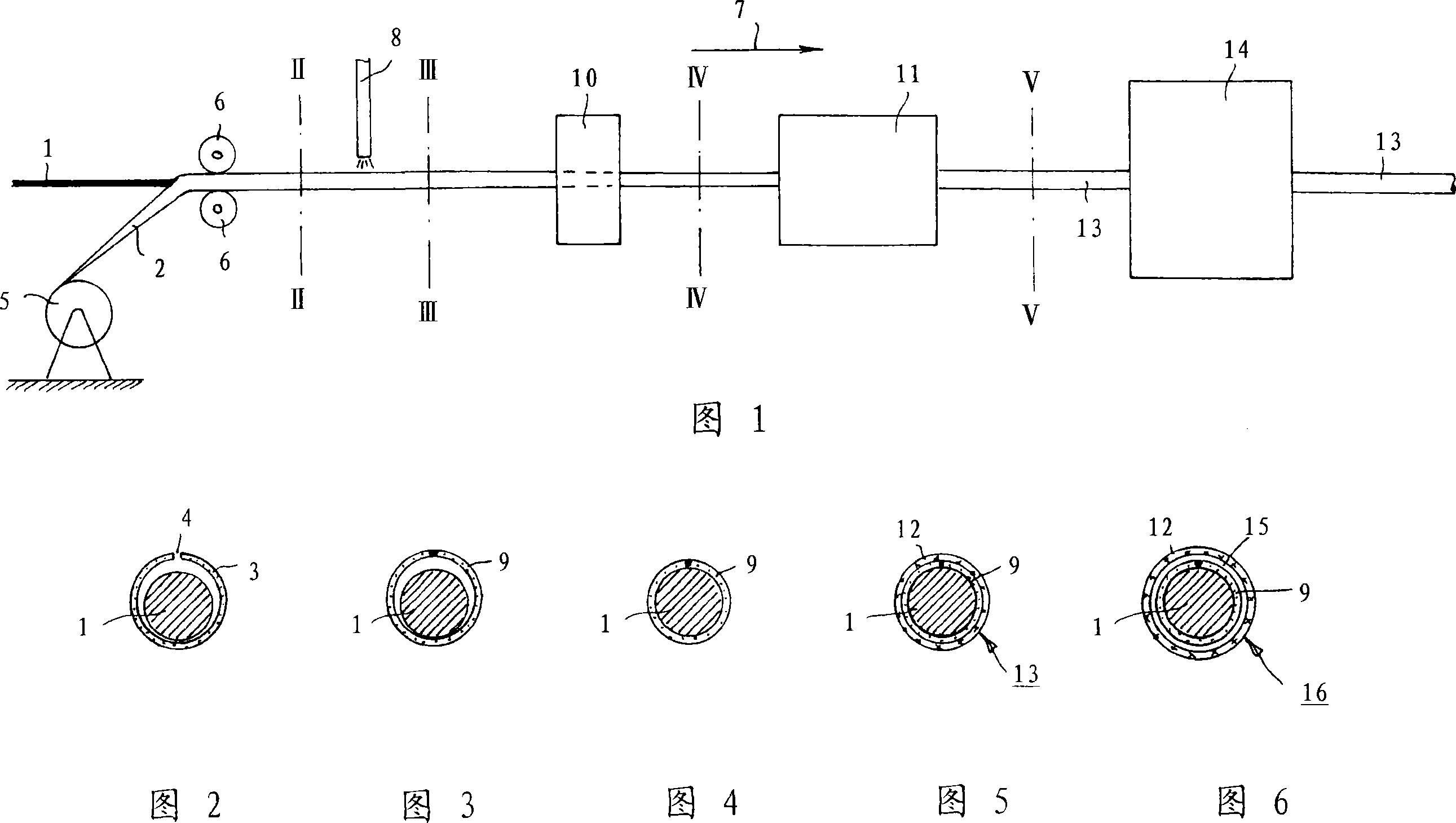

[0016] 1 denotes a metal support, which can be embodied as a strip, cable, or tube. It preferably consists of steel and can also function as the tensile central element of the superconductor to be produced. The support body 1 preferably has an outer diameter of between 0.5 mm and 3.0 mm.

[0017] A slit tube 3 is formed around the support body 1 with a metal substrate provided as a band 2 which has been textured by pretreatment, advantageously as close as possible to the support body 1 . Its longitudinally extending edges adjoin one another at a firstly still open slot 4 . In this case, the strip 2 is pulled from a reel 5 and the slit tube 3 is formed in a forming device represented by rollers 6 . It consists, for example, of nickel, copper or iron or alloys. The strip 2 has already been given a biaxial texture in a preprocessing stage, for example. It preferably has a thickness between 50 μm and 150 μm.

[0018] The support body 1 and the slit tube 3 are preferably moved...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com