Yttrium barium copper oxide fluorine-free sol and preparation of high temperature superconducting film

A high-temperature superconducting film, yttrium barium copper oxide technology, applied in the field of microelectronic materials, can solve the problem of reducing the preparation efficiency of YBCO superconducting film, up to ten or even dozens of hours, up to ten or even dozens of hours, etc. problems, to achieve the effect of shortening the heat treatment time, uniform performance and low porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

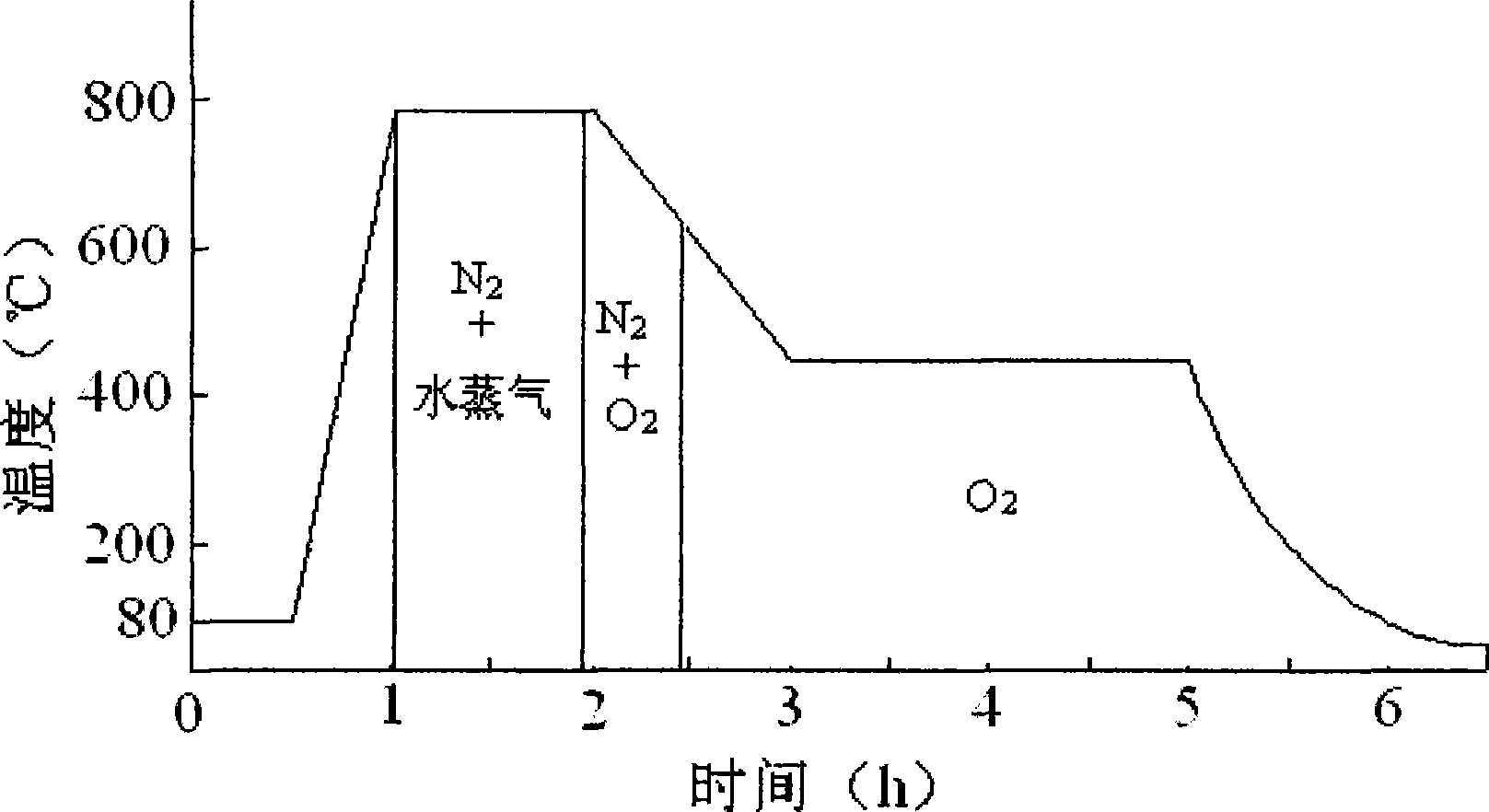

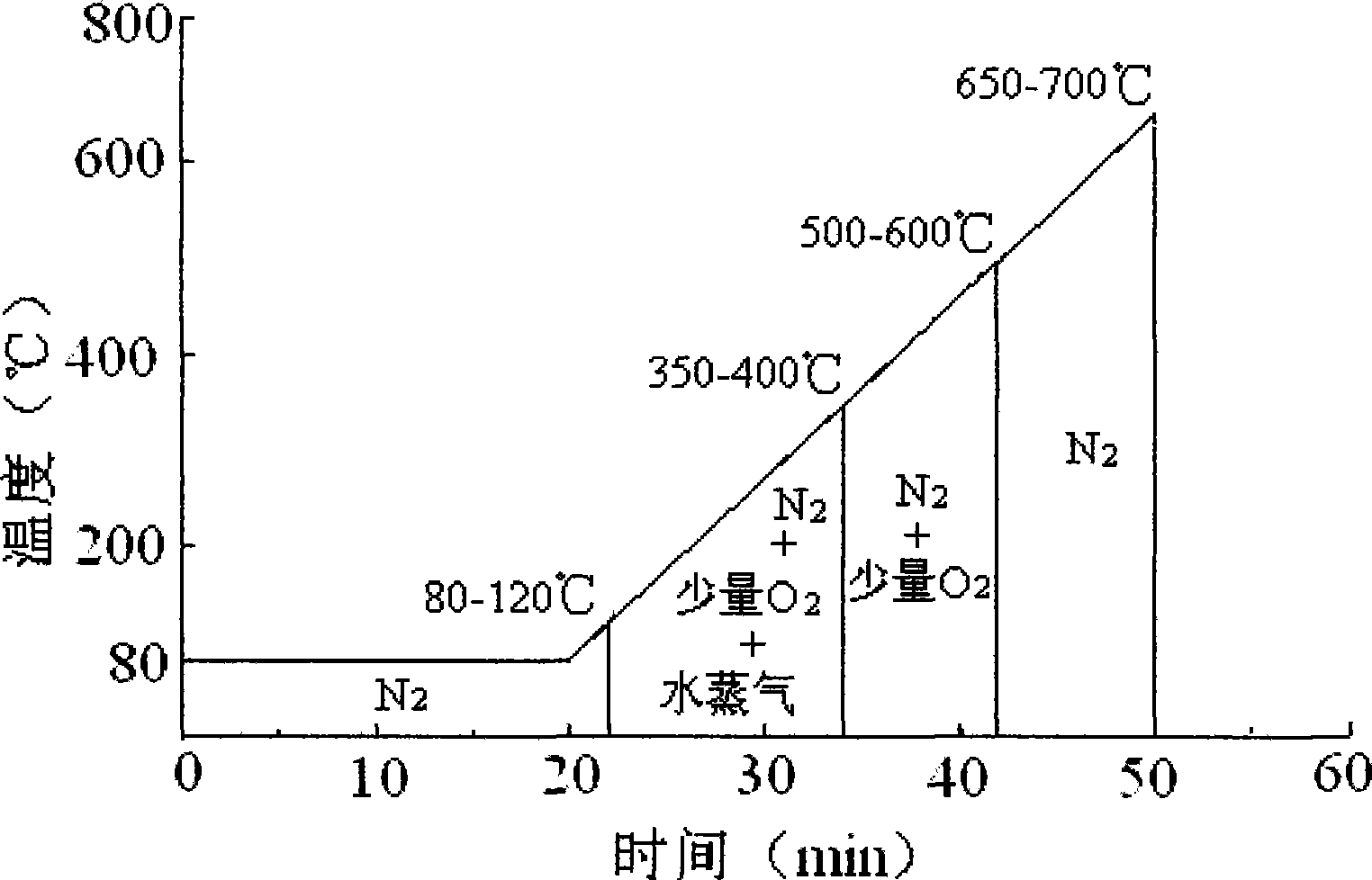

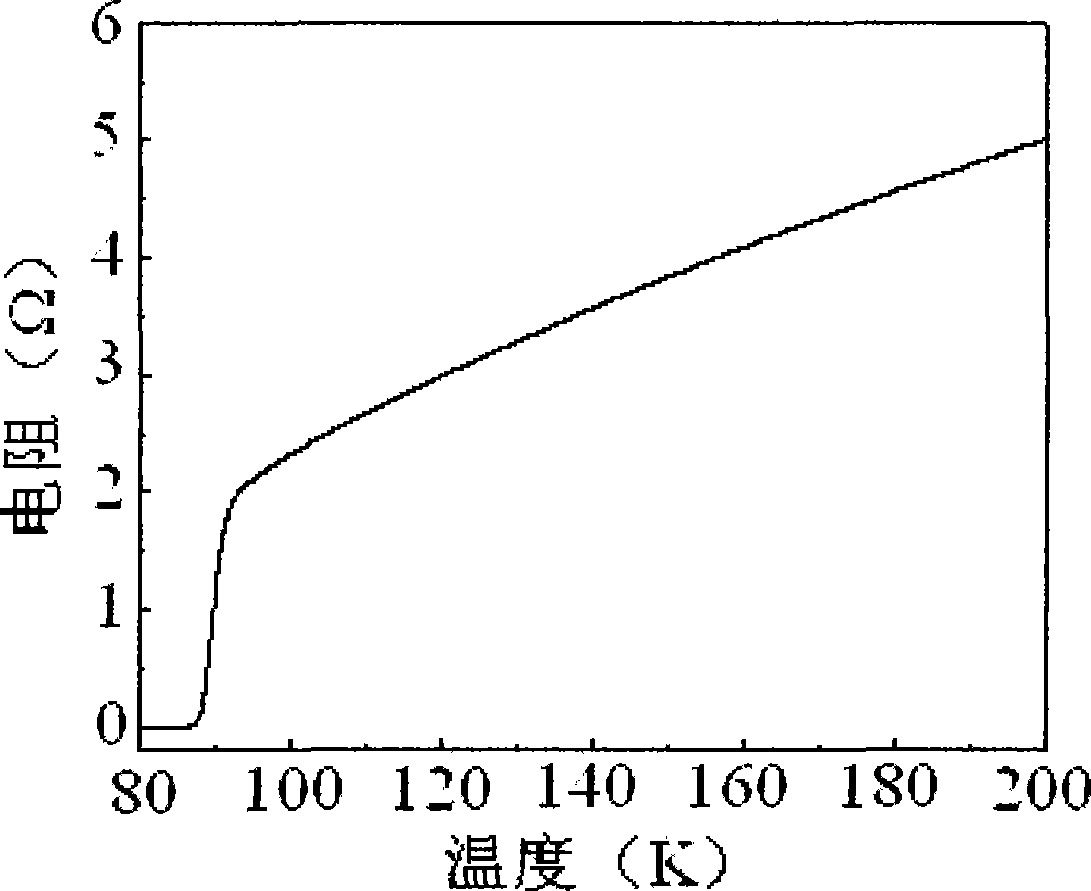

[0071] Take yttrium acetate, methanol, and diethylenetriamine at a molar ratio of 1:10:1.5, respectively, dissolve yttrium acetate in methanol, then add diethylenetriamine, and stir to dissolve to form solution A; at a molar ratio of 1:10: 3. Take barium acetate, methanol and lactic acid respectively, dissolve barium acetate in methanol, then add lactic acid, stir and dissolve at 25°C to form solution B; take copper acetate, methanol and Acrylic acid, dissolve copper acetate in methanol, add acrylic acid, stir and dissolve at 25°C to form solution C; mix and stir the prepared solution A, solution B and solution C to obtain yttrium barium copper oxide fluorine-free sol, Control the molar ratio of yttrium ion, barium ion and copper ion in the yttrium barium copper oxide fluorine-free sol to be 1:2:3; The body was pulled and coated on a single crystal LAO (001) substrate to prepare a layer of yttrium barium copper oxide gel film. The yttrium-barium-copper-oxygen gel film was pla...

Embodiment 2

[0073]Take yttrium acetate, ethylene glycol methyl ether and ethanolamine respectively at a molar ratio of 1:40:5, dissolve yttrium acetate in ethylene glycol methyl ether, then add ethanolamine, stir and dissolve to form solution A; molar ratio 1: 80:5, take barium hydroxide, ethylene glycol methyl ether and lactic acid respectively, dissolve barium hydroxide in ethylene glycol methyl ether, then add lactic acid, stir and dissolve at 40°C to form solution B; Ratio 1:40:10, take copper acetate, ethylene glycol methyl ether and α-methacrylic acid respectively, dissolve copper acetate in ethylene glycol methyl ether, then add α-methacrylic acid, and stir at 40°C After dissolving, solution C is formed; the prepared solution A, solution B and solution C are mixed and stirred to obtain yttrium barium copper oxide fluorine-free sol, and the yttrium ion, barium ion and copper ion in the yttrium barium copper oxide fluorine-free sol are controlled The molar ratio is 1:2:4; at room tem...

Embodiment 3

[0075] According to the molar ratio of 1:25:3.2, take yttrium acetate, ethanol and diethanolamine respectively, dissolve yttrium acetate in ethanol, then add diethanolamine, stir and dissolve to form solution A; according to the molar ratio of 1:45:4, respectively Take barium acetate, ethanol and lactic acid, dissolve barium acetate in ethanol, then add lactic acid, stir and dissolve at 35°C to form solution B; take copper acetate, ethanol and acrylic acid respectively in a molar ratio of 1:25:6 acid, dissolve copper acetate in ethanol, then add propionic acid, stir and dissolve at 35°C to form solution C; mix and stir the prepared solution A, solution B and solution C to obtain yttrium barium copper oxide Fluoride-free sol, control the molar ratio of yttrium ion, barium ion and copper ion in this yttrium barium copper oxide fluorine-free sol to be 1:2:3.6; Fluorosol is used as a precursor, and a yttrium barium copper oxide gel film is prepared on a lanthanum aluminate single ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com