Preparation method of nano composite ytrium barium copper oxide superconducting bulks

A yttrium barium copper oxide and nanocomposite technology is applied in the field of preparation of nanocomposite yttrium barium copper oxide superconducting bulk materials, can solve the problems of unreachable, unimpeded current-carrying capacity limitation, slow growth and solidification process, etc., and achieves high efficiency , the process is simple, the effect of high superconductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

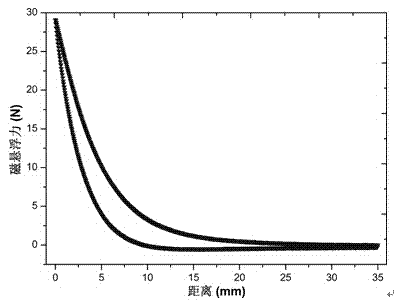

Examples

Embodiment 1

[0027] (1) Preparation of solid phase powder:

[0028] Mix 65.8415g BaO and 34.1585g CuO primary powder evenly, that is, the molar ratio of BaO and CuO primary powder is 1:1, and make BaCuO by solid state reaction method 2 Precursor powder; take 39.3842g Y 2 o 3 Nano powder (average particle size 50nm) and 40.6158g BaCuO 2 Mix the precursor powder and add 0.8g CeO at the same time 2 Initial powder, ie Y 2 o 3 Nanopowder and BaCuO 2 The molar ratio of the precursor powder is 1:1, and 1% (w / w) CeO is added at the same time 2 Initial powder, mixed evenly, as solid phase powder;

[0029] (2) Preparation of liquid phase source powder:

[0030] Take 9.8517g Yb 2 o 3 Mix evenly with 38.3308g BaO, 31.8175g CuO initial powder, namely Yb 2 o 3 The molar ratio of BaO and CuO initial powder is 1:10:16, as the liquid phase source powder;

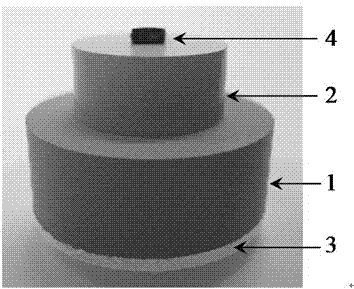

[0031] (3) Press the precursor block:

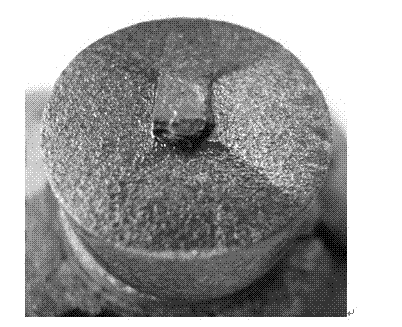

[0032] Take 5g of solid phase powder into cylindrical mold 1 (diameter 16mm) and press it into a sol...

Embodiment 2

[0043] In step (1) of preparing solid phase powder, prepare BaCuO 2 The raw materials used for the precursor powder and the preparation method are the same as in Example 1, and then 39.3842g Y 2 o 3 Nano powder (average particle size 50nm) and 40.6158g BaCuO 2 Mix the precursor powder and add 0.4g CeO at the same time 2 Initial powder, ie Y 2 o 3 Nanopowder and BaCuO 2 The molar ratio of the precursor powder is 1:1, and 0.5% (w / w) CeO is added at the same time 2 The initial powder, mixed evenly, is used as solid phase powder.

[0044] In the step (3) of pressing the precursor block, take 5g of solid phase powder and put it into cylindrical mold 1 (diameter 16mm) to press into a solid phase block; take 12.5g of liquid phase source powder and put it into cylindrical mold 2 (diameter 26mm) , pressed into a liquid phase source block; that is, the mass ratio of the solid phase powder to the liquid phase source powder is 1:2.5, and the diameter of the cylindrical mold 2 is 10...

Embodiment 3

[0048] In step (1) of preparing solid phase powder, prepare BaCuO 2 The raw materials used for the precursor powder and the preparation method are the same as in Example 1, and then 39.3842g Y 2 o 3 Nano powder (average particle size 50nm) and 40.6158g BaCuO 2 Mix the precursor powder and add 1.2g CeO at the same time 2 Initial powder, ie Y 2 o 3 Nanopowder and BaCuO 2 The molar ratio of the precursor powder is 1:1, and 1.5% (w / w) CeO is added at the same time 2 The initial powder, mixed evenly, is used as solid phase powder.

[0049] In the step (3) of pressing the precursor block, take 5g of solid phase powder and put it into cylindrical mold 1 (diameter 16mm) to press into a solid phase block; take 17.5g of liquid phase source powder and put it into cylindrical mold 2 (diameter 26mm) , pressed into a liquid phase source block; that is, the mass ratio of the solid phase powder to the liquid phase source powder used is 1:3.5, and the diameter of the cylindrical mold 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com