Method for separating iron, vanadium and titanium from vanadium-titanium magnetite

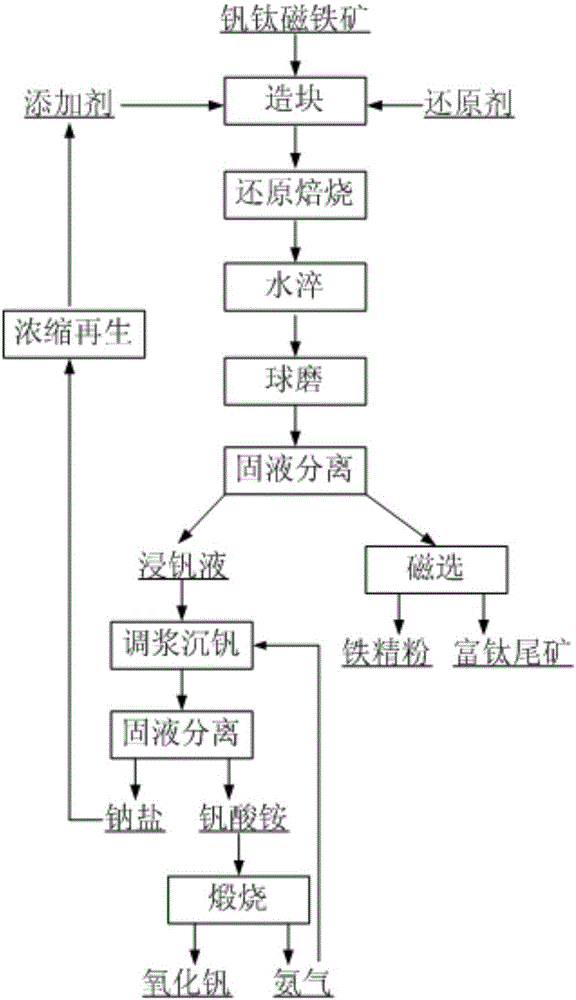

A technology for separating vanadium titanomagnetite and iron, applied in the fields of titanium, separating iron and vanadium, can solve the problems of complex separation process, and achieve the effects of simple process, high metal recovery rate and high resource utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Add 20% sodium sulfate, 12% coal powder and 1% bentonite to the vanadium-titanium magnetite in Table 1, mix and pelletize, dry and roast in a muffle furnace at 1100°C for 30 minutes, water quench the obtained calcined sand, and Hot ball milling for 30 minutes, solid-liquid ratio of 1:3, filtering to obtain vanadium leaching solution and vanadium leaching slag, and magnetically separating the vanadium leaching slag under a magnetic field strength of 0.1T to obtain iron concentrate powder and titanium-rich tailings.

[0065] The obtained iron fine powder contains 71.3% iron, the iron recovery rate is 88.6%, and the titanium-rich tailings contain TiO 2 39.8%, titanium yield 89.5%, vanadium leaching rate 58.2%.

Embodiment 2

[0067] Add 15% sodium carbonate, 9% coal powder and 1% bentonite to the vanadium-titanium magnetite in Table 1, mix and make pellets, dry and roast in a muffle furnace at 1150°C for 60 minutes, water quench the obtained calcined sand, and Hot ball milling for 30 minutes, solid-liquid ratio of 1:5, filtering to obtain vanadium leaching solution and vanadium leaching slag, and magnetic separation to separate vanadium leaching slag under a magnetic field strength of 0.2T to obtain iron concentrate powder and titanium-rich tailings.

[0068] The obtained iron fine powder contains 79.6% iron, the iron recovery rate is 95.7%, and the titanium-rich tailings contain TiO 2 50.5%, titanium yield 93.0%, vanadium leaching rate 89.8%.

Embodiment 3

[0070] Add 10% sodium hydroxide, 9% coal powder and 1% bentonite to the vanadium-titanium magnetite in Table 1, mix and make pellets, dry and roast in a muffle furnace at 900°C for 90 minutes, and water quench the obtained calcined sand. Leach for 60 minutes by ball milling while hot, with a solid-to-liquid ratio of 1:8, filter to obtain the vanadium leaching solution and vanadium leaching slag, and magnetically separate the vanadium leaching slag under a magnetic field strength of 0.15T to obtain iron concentrate powder and titanium-rich tailings.

[0071] The obtained iron fine powder contains 75.5% iron, the iron recovery rate is 90.4%, and the titanium-rich tailings contain TiO 2 41.5%, titanium yield 91.2%, vanadium leaching rate 91.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com