Pretreatment method and device for utilizing domestic garbage as fuel

A technology for household waste and waste fuel is applied in the field of pretreatment of household waste, which can solve the problems of increased energy consumption, easily damaged equipment, and low calorific value of waste fuel, so as to reduce moisture content and inorganic content, and reduce pollutant emissions. , the effect of saving conventional energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

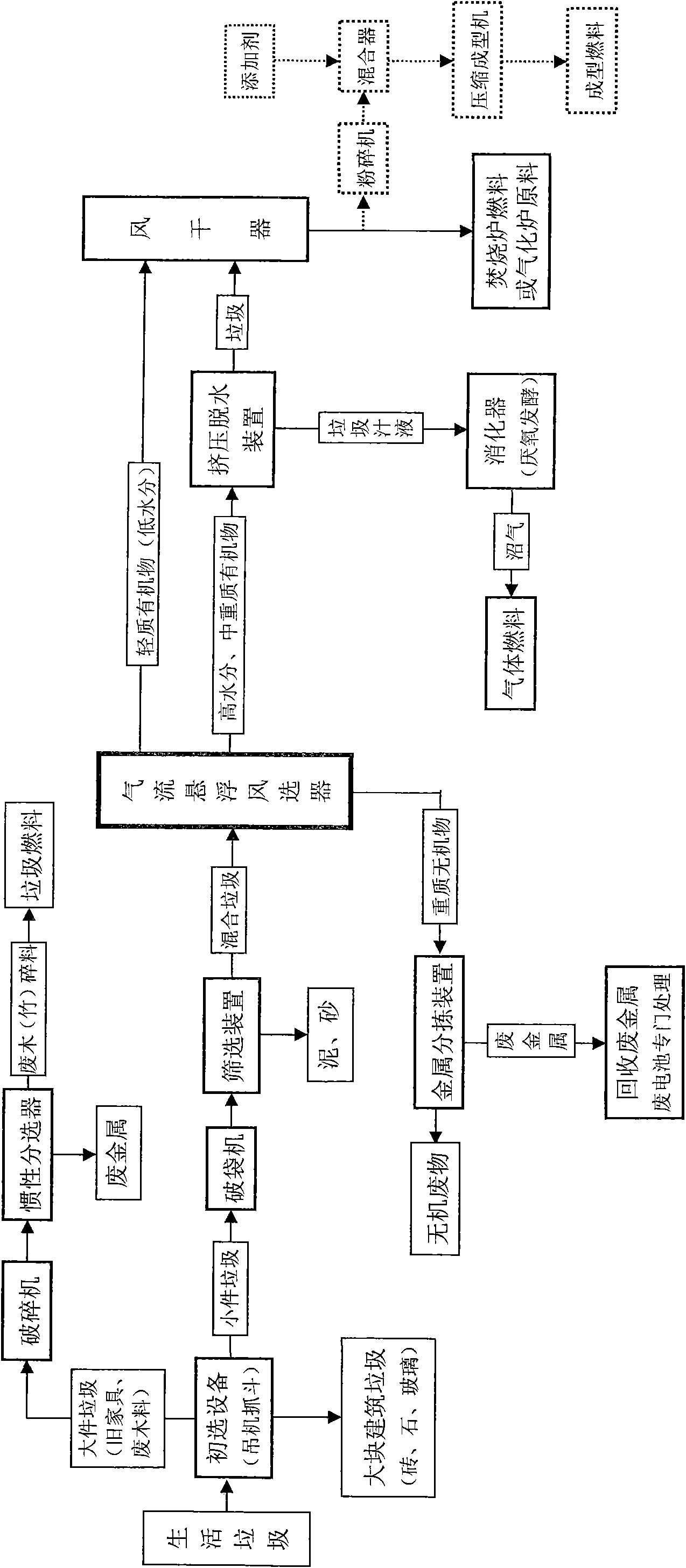

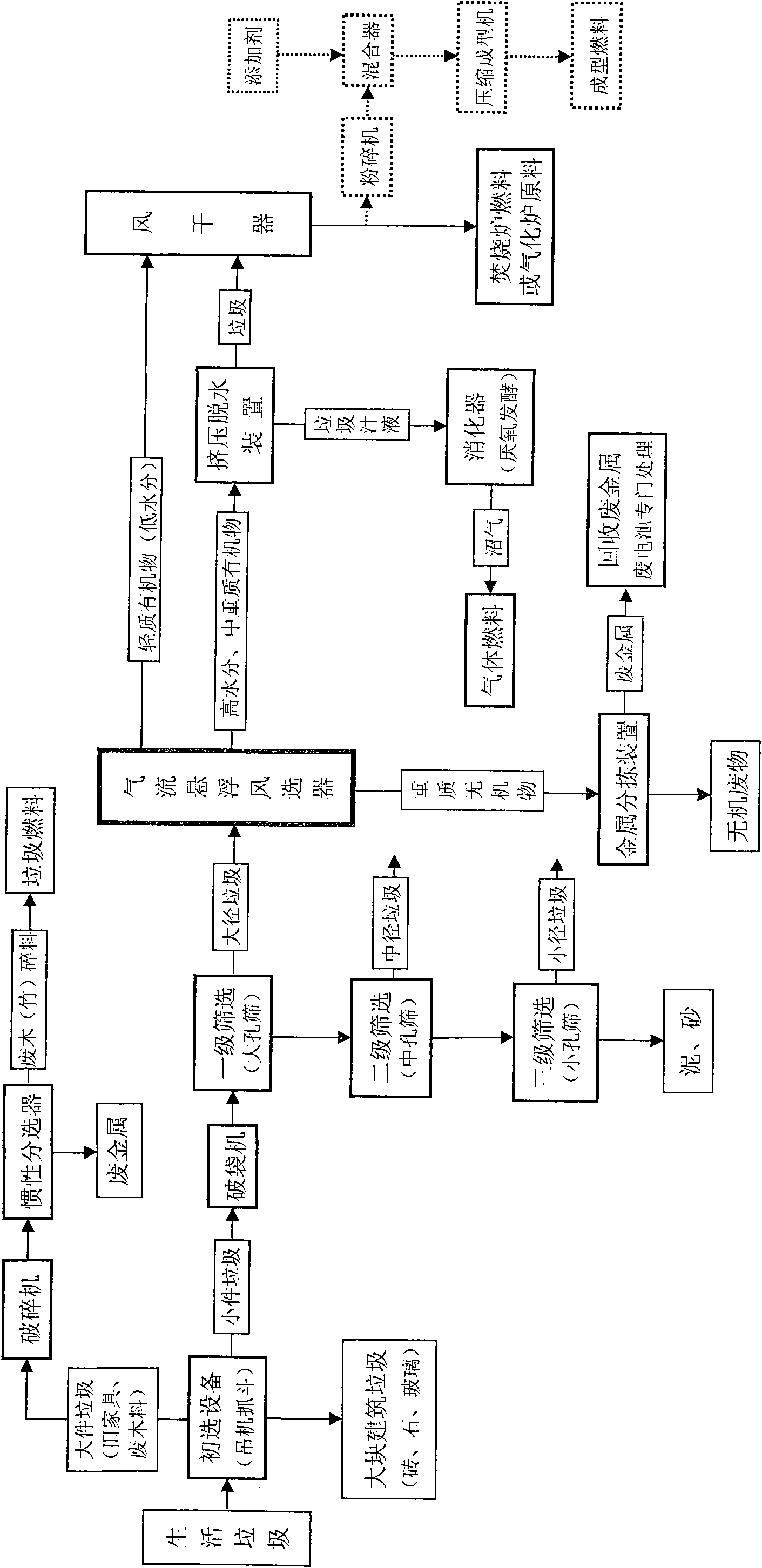

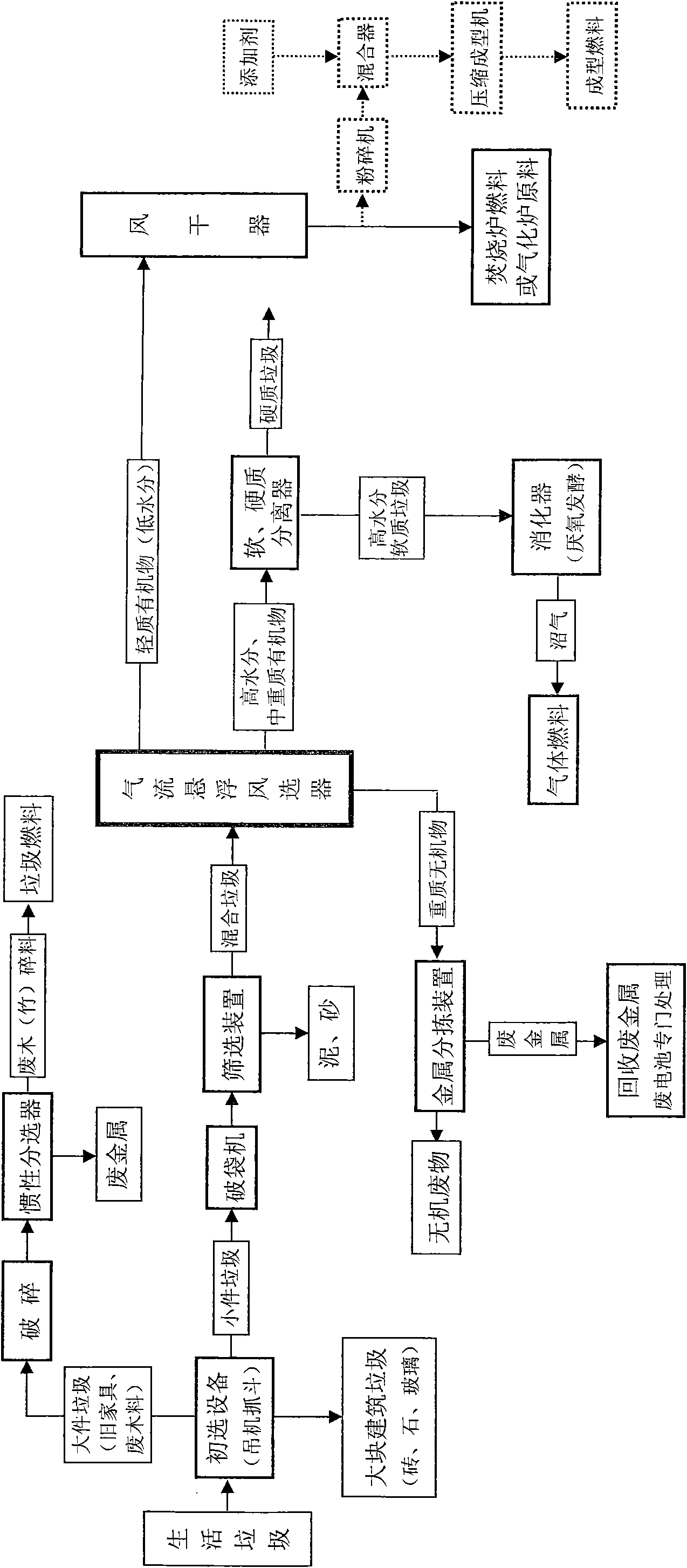

[0025] figure 1 In the shown embodiment, the process flow of the domestic waste pretreatment method is mainly composed of primary selection, large-size waste crushing / small-size waste bag breaking, screening, air suspension winnowing, high-moisture waste dehydration and air-drying processes, wherein: primary selection The process uses the grab operation of the crane to send large pieces of garbage into the crusher for crushing, remove large pieces of construction waste (bricks, stones, glass) from the garbage storage pit, and leave small pieces of garbage in the storage pit; The pieces of garbage are mainly waste furniture, waste wood and large pieces of worn-out fiber fabrics. After being processed by the crusher, they are sent to the inertial sorting device for sorting. The sorted waste metals are recycled, and the sorted waste wood (bamboo) , Fiber fabric scraps are used as fuel; small pieces of garbage are sent to the bag breaking device to break the bag and then sent to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com