Method of preparing ammonium polyphosphate by using phosphoric acid by wet process and yellow phosphorus as raw materials

A technology of ammonium polyphosphate and wet-process phosphoric acid, which is applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of not being fully soluble in water and high production costs, so as to benefit comprehensive fertilizer efficiency and reduce the cost of impurity removal , The effect of water insoluble matter reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

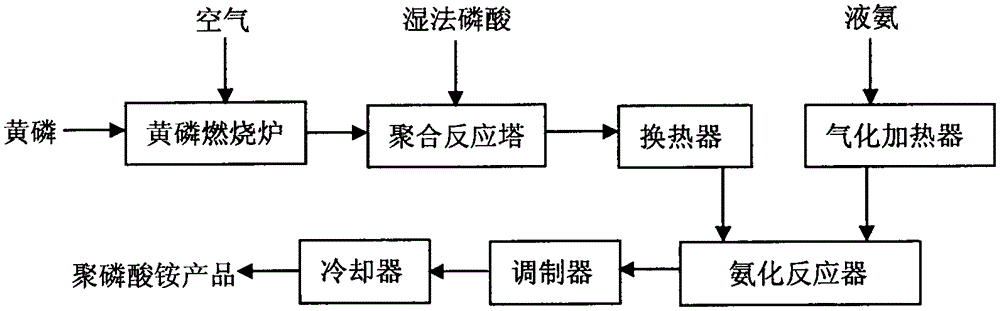

Image

Examples

Embodiment 1

[0025] First, the yellow phosphorus flows into the horizontal combustion furnace for high-temperature combustion. The combustion furnace is surrounded by a water circulation jacket for heat exchange and steam bubbles, and the generated hot water and steam are passed into the yellow phosphorus pool, the yellow phosphorus tank and the jacket of the yellow phosphorus pipe. Heating heating and heat preservation, the high temperature P generated by the combustion of yellow phosphorus 2 O 5 The flue gas enters the polymerization reaction tower, folds P 2 O 5 The wet-process phosphoric acid with a content of 40% enters the polymerization reaction tower at the same time, and the wet-process phosphoric acid, P 2 O 5 The mixture of equal composition undergoes polymerization reaction to generate polyphosphoric acid. The temperature of the mixture is relatively high. The circulating acid-resistant pump and acid-resistant pipeline are connected to the heat exchanger to control the liqui...

Embodiment 2

[0027] First, the yellow phosphorus flows into the horizontal combustion furnace for high-temperature combustion. The combustion furnace is surrounded by a water circulation jacket for heat exchange and steam bubbles, and the generated hot water and steam are passed into the yellow phosphorus pool, the yellow phosphorus tank and the jacket of the yellow phosphorus pipe. Heating heating and heat preservation, the high temperature P generated by the combustion of yellow phosphorus 2 O 5 The flue gas enters the polymerization reaction tower, folds P 2 O 5 The wet-process phosphoric acid with a content of 50% enters the polymerization reaction tower at the same time, and the wet-process phosphoric acid, P 2 O 5 The mixture of equal composition undergoes polymerization reaction to generate polyphosphoric acid. The temperature of the mixture is relatively high. The circulating acid-resistant pump and acid-resistant pipeline are connected to the heat exchanger to control the liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com