Method for preparing baking-free brick from yellow phosphorus slag and modified phosphogypsum

A technology of phosphogypsum and yellow phosphorus slag is applied in the field of non-burning bricks, which can solve the problems of high cost, unfavorable industrial production, long brick curing time, etc., and achieves the effects of good quality, high utilization rate and shortened production cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

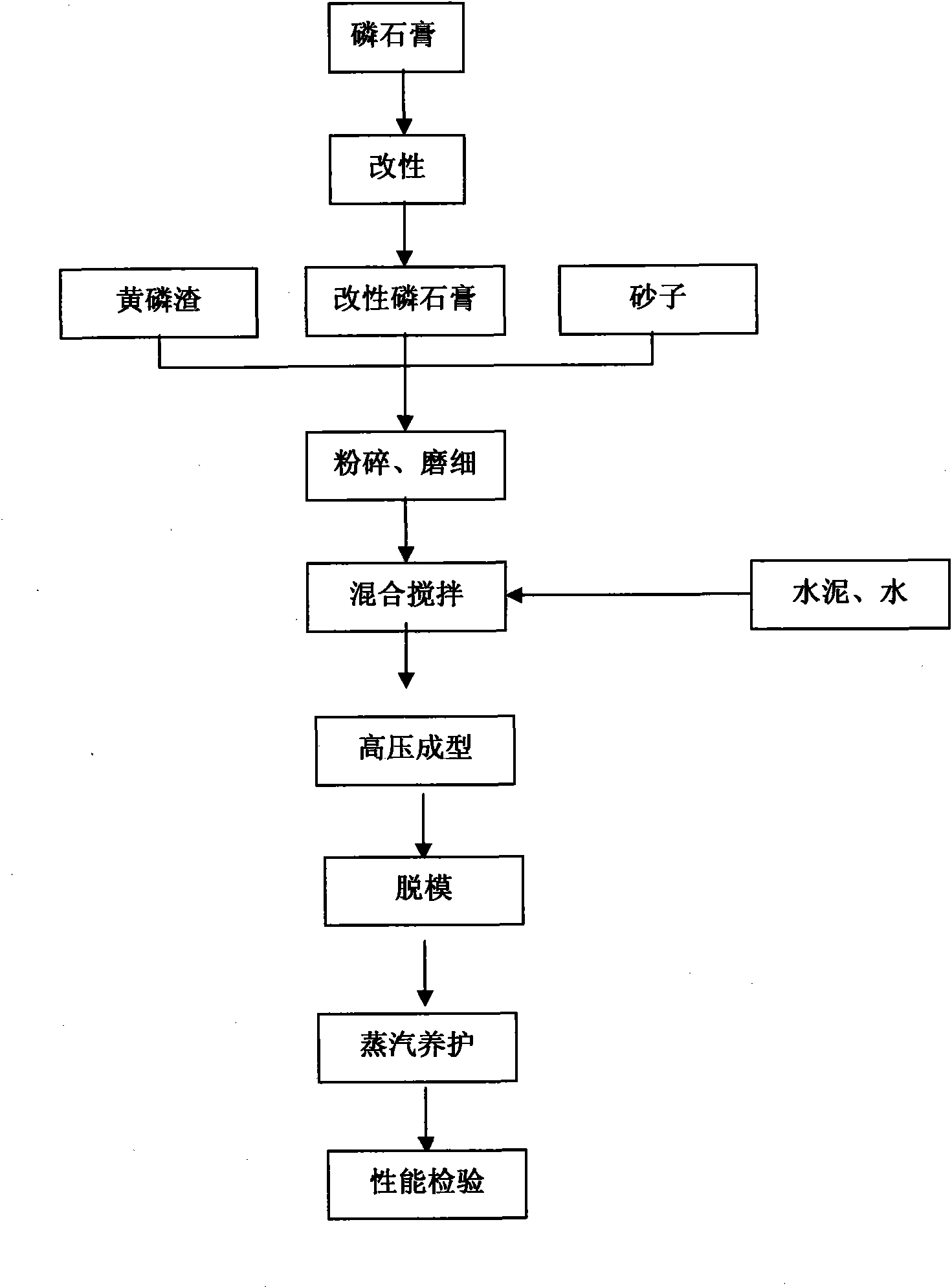

Method used

Image

Examples

Embodiment 1

[0044] Crush 75% of yellow phosphorus slag, 25% of modified phosphogypsum, and 8% of sand (percentage by weight) until the particle size is less than 3mm, then add 5% of cement and 7% of water for mixing, high-pressure molding, demoulding, 60-80 ℃ steam curing, and finally the performance test of the product. Among them, the steam curing time is about 6 to 8 hours.

[0045] The measured product performance is as follows:

[0046] Compressive strength 10.6Mpa;

[0047] Flexural strength 2.7Mpa;

[0048] Meet the requirements of the standard "JC422-1991 (1996) non-fired ordinary bricks".

Embodiment 2

[0050] After pulverizing 72% of yellow phosphorus slag, 28% of modified phosphogypsum, and 5% of sand (percentage by weight) to a particle size of less than 3mm, add 5% of cement and 8% of water to mix and stir. Other procedures are the same as in Example 1.

[0051] The measured product performance is as follows:

[0052] Compressive strength 10.8Mpa;

[0053] Flexural strength 2.3Mpa;

[0054] Meet the requirements of the standard "JC422-1991 (1996) non-fired ordinary bricks".

Embodiment 3

[0056]68% of yellow phosphorus slag, 32% of modified phosphogypsum, and 10% of sand (percentage by weight) were pulverized to a particle size of less than 3mm, then mixed with 3% of cement and 10% of water for mixing. Other procedures were the same as in Example 1.

[0057] The measured product performance is as follows:

[0058] Compressive strength 10.2Mpa;

[0059] Flexural strength 2.3Mpa;

[0060] It meets the requirements of the standard "JC422-1991 (1996) non-fired common brick".

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com