High strength phosphogypsum brick and manufacturing method thereof

A gypsum brick and high-strength technology, which is applied in the field of high-strength phosphogypsum brick and its production, can solve the problems of phosphogypsum brick strength, durability limitation, unsuitable for use in highway engineering and municipal engineering, etc., and achieves clear type composition and type composition Simple and durable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

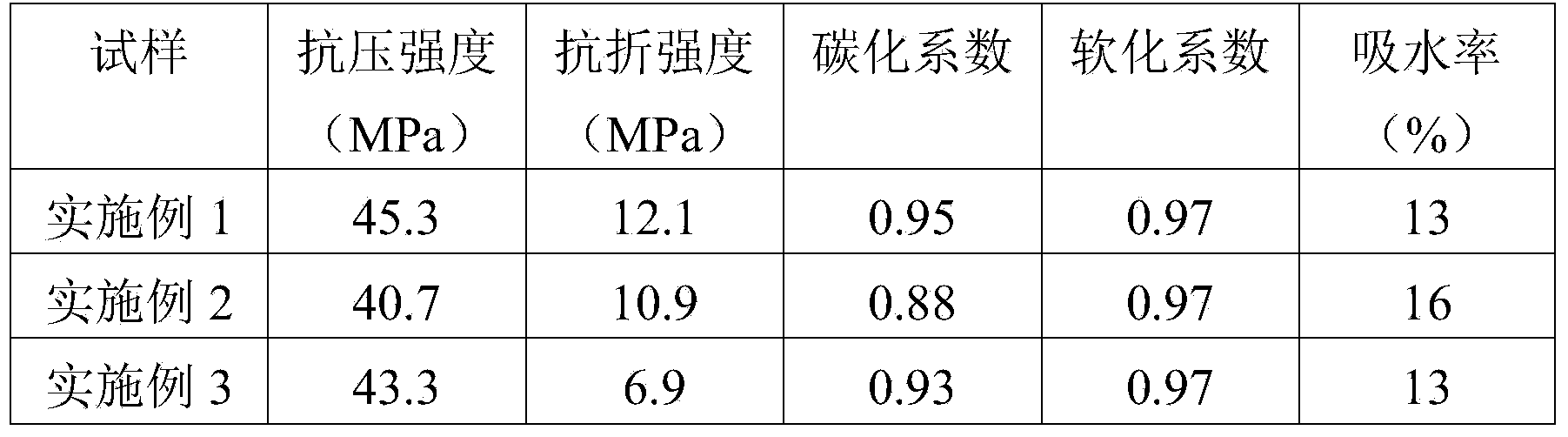

Embodiment 1

[0036] Prepare raw materials according to the batch test volume of 3000 pieces, 2000kg of phosphogypsum, 5300kg of yellow phosphorus slag, 150kg of quicklime, and 2550kg of fine aggregate.

[0037] First mix and grind the dried yellow phosphorus slag and quicklime; then uniformly measure and mix the mixed grinding material with phosphogypsum and fine aggregate; The brick body is made by a hydraulic vibration forming machine; the finished product is made by 1.35MPa saturated steam curing.

[0038] Test results:

[0039] Compressive strength: 45.3MPa;

[0040] Flexural strength: 12.1MPa;

[0041] Softening coefficient: 0.95;

[0042] Carbonization coefficient: 0.97;

[0043] Water Absorption: 13%.

Embodiment 2

[0045] Prepare raw materials according to the batch test volume of 3000 pieces, 3900kg of phosphogypsum, 4000kg of yellow phosphorus slag, 100kg of quicklime, and 2000kg of fine aggregate.

[0046] First mix and grind the dry yellow phosphorus slag and quicklime; then uniformly measure and mix the mixed grinding material with phosphogypsum and fine aggregate; The brick body is made by a hydraulic vibration forming machine; the finished product is made by 1.55MPa saturated steam curing.

[0047] Test results:

[0048] Compressive strength: 40.7MPa;

[0049] Flexural strength: 10.9MPa;

[0050] Softening coefficient: 0.88;

[0051] Carbonization coefficient: 0.97;

[0052] Water Absorption: 16%.

Embodiment 3

[0054] Prepare raw materials according to the batch test volume of 3000 pieces, 3000kg of phosphogypsum, 4000kg of yellow phosphorus slag, 100kg of quicklime, and 2900kg of fine aggregate.

[0055] First mix and grind the dry yellow phosphorus slag and quicklime; then uniformly measure and mix the mixed grinding material with phosphogypsum and fine aggregate; The brick body is made by a hydraulic vibration forming machine; the finished product is made by 1.45MPa saturated steam curing.

[0056] Test results:

[0057] Compressive strength: 43.3MPa;

[0058]Flexural strength: 6.9MPa;

[0059] Softening coefficient: 0.93;

[0060] Carbonization coefficient: 0.97;

[0061] Water Absorption: 13%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com