Method for producing ultra-pure yellow phosphorus

A production method, yellow phosphorus technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of low removal rate, explosion, and increased purification cost, and achieve easy industrial production and save the recovery system , the effect of reducing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

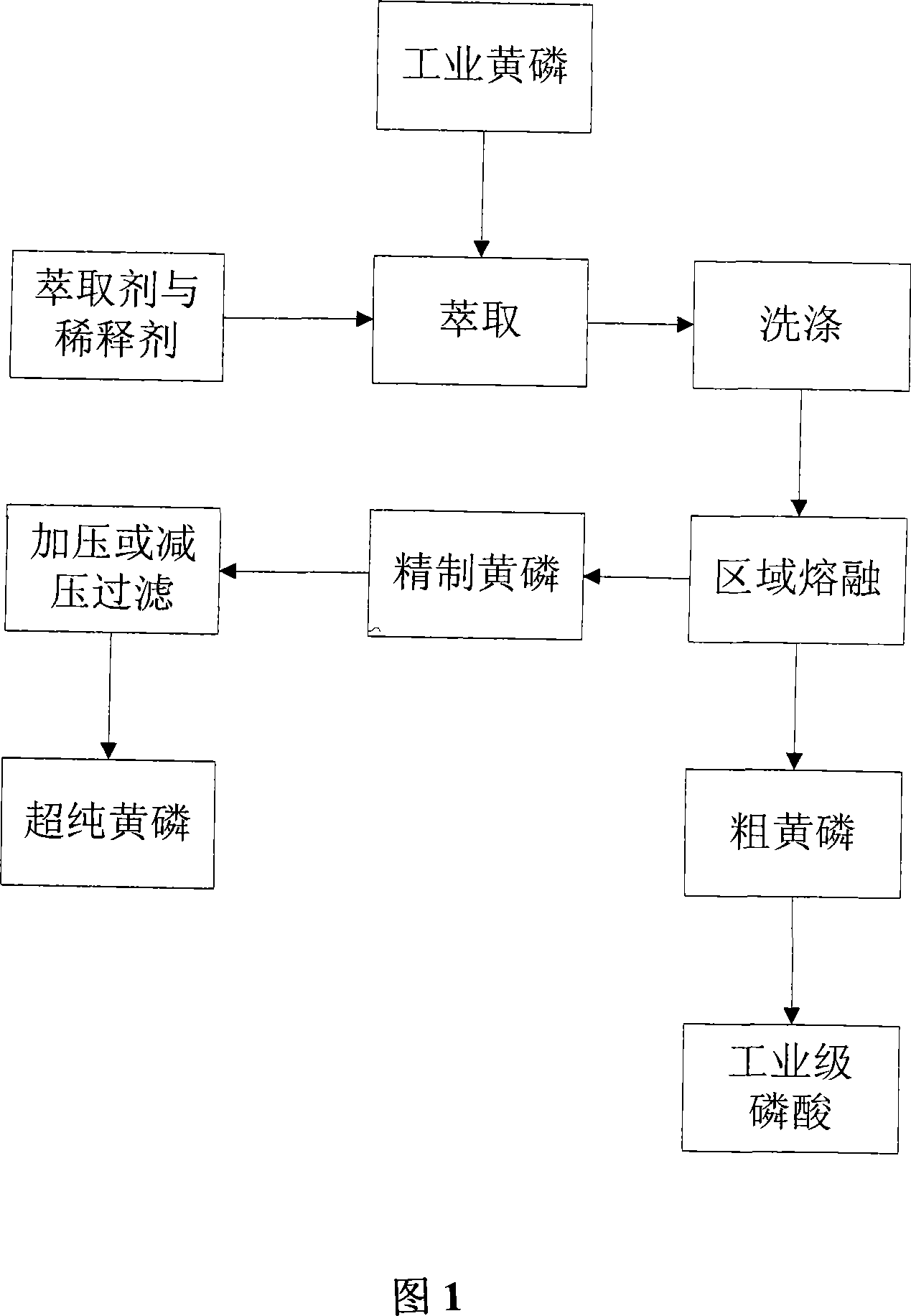

[0045] The process flow of this embodiment is shown in Figure 1, and the process steps are extraction, zone melting, and vacuum microfiltration in sequence.

[0046] 1. Extraction

[0047] The extractant is di(2-ethylhexyl)phosphoric acid, and the diluent is kerosene. In the organic phase, the volume percentage of the extractant is 15%, and the volume percentage of the diluent is 85%. The volume ratio of the organic phase to the industrial yellow phosphorus is 1:3.

[0048] The extraction reactor is an ordinary glass jacketed reactor, in which hot water circulates at 70°C, then the organic phase is added, and nitrogen is introduced into the reactor. When the air in the reactor is completely exhausted, the industrial yellow phosphorus The phosphorus is pressed into the reactor from the phosphorus pressing tank, and the extraction is carried out under the protection of nitrogen, the stirring line speed is 200r / min, and the stirring time is 45min. After stopping the stirring, d...

Embodiment 2

[0075] The process flow of this embodiment is shown in Figure 1, and the process steps are extraction, zone melting, and vacuum microfiltration in sequence.

[0076] 1. Extraction

[0077] The extractant is tributyl phosphate, and the diluent is paraffin oil. In the organic phase, the volume percentage of the extractant is 30%, and the volume percentage of the diluent is 70%. The volume ratio of the organic phase to the industrial yellow phosphorus is 1:3.

[0078] The extraction reactor is an ordinary glass jacketed reactor, in which hot water circulates at 70°C, then the organic phase is added, and nitrogen is introduced into the reactor. When the air in the reactor is completely exhausted, the industrial yellow phosphorus Press it into the reactor from the phosphorus pressing tank, and extract it under the protection of nitrogen. The stirring line speed is 600r / min, and the stirring time is 35min. After stopping the stirring, discharge the organic phase, wash the yellow p...

Embodiment 3

[0093] The process flow of this embodiment is shown in Figure 1, and the process steps are extraction, zone melting, and vacuum microfiltration in sequence.

[0094] 1. Extraction

[0095] Extractant is two (2-ethylhexyl) phosphoric acid and tributyl phosphate, the volume ratio of two (2-ethylhexyl) phosphoric acid and tributyl phosphate is 1: 1, diluent is paraffin oil, in organic phase, The volume percentage of the extractant is 20%, and the volume percentage of the diluent is 80%. The volume ratio of the organic phase to the industrial yellow phosphorus is 1:2.

[0096] The extraction reactor is an ordinary glass jacketed reactor, in which hot water circulates at 70°C, then the organic phase is added, and nitrogen is introduced into the reactor. When the air in the reactor is completely exhausted, the industrial yellow phosphorus Press it into the reactor from the phosphorus pressing tank, and extract it under the protection of nitrogen, the stirring line speed is 800r / mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com