Catalyst for decomposing hydrogen phosphide gas as well as preparation method and application thereof

A catalyst and phosphine technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, chemical instrument and method, etc., can solve the problems of expensive, unsuitable for industrial production, etc., and achieve cost Inexpensive, highly dispersed, easy to prepare

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

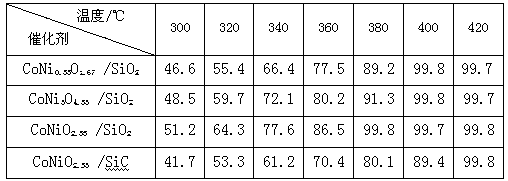

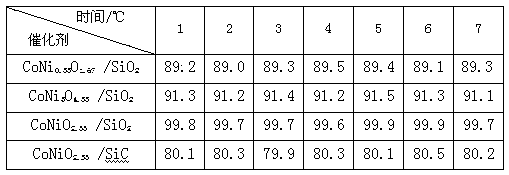

Embodiment 1

[0026] Take 6gCo(NO 3 ) 2 ·6H 2 O and 2gNi(NO 3 ) 2 Dissolve 6H2O in 200mL distilled water, add 12.3g SiO in sequence 2 and 4gNa 3 C 6 h 5 o 7 2H 2 O (sodium citrate), fully ultrasonic (400W, 20min) and stirring; under the condition of water bath (80℃) and stirring, add concentrated ammonia water drop by drop to the above solution until the pH reaches 8; Suction filtration, repeated washing with distilled water, drying at 80°C, and grinding into a powdery precursor; calcining the precursor at 400°C for 4 h to obtain the product. The ICP detection showed that the molar ratio of Co, Ni and O in the product was CoNi 0.33 o 1.67 / SiO 2 , the loading of active components of double metal oxides is 15%.

Embodiment 2

[0028] Take 2gCo(NO 3 ) 2 ·6H 2 O and 6gNi(NO 3 ) 2 ·6H 2 O and dissolved in 200mL distilled water, add 11.9g SiO 2 and 2gNa 3 C 6 h 5 o 7 2H 2 O (sodium citrate), fully ultrasonic (400W, 20min); under the conditions of water bath (60℃) and stirring, add concentrated ammonia water drop by drop to the above solution until the pH reaches 8; the resulting jelly is vacuum filtered , washed repeatedly with distilled water, dried at 80°C, and ground into a powdery precursor; the precursor was calcined at 400°C for 4 h to obtain the product. It has been detected that the molar ratio of Co, Ni and O in the product is CoNi 3 o 4.33 / SiO 2 , the loading of active components of double metal oxides is 15%.

Embodiment 3

[0030] Take 4gCo(NO 3 ) 2 ·6H 2 O and 4gNi(NO 3 ) 2 ·6H 2 O and dissolved in 200mL distilled water, add 12.2g SiO 2 and 3gNa 3 C 6 h 5 o 7 2H 2 O (sodium citrate), fully ultrasonic (400W, 20min); under the conditions of water bath (70℃) and stirring, add concentrated ammonia water drop by drop to the above solution until the pH reaches 7; the obtained jelly is vacuum filtered , washed repeatedly with distilled water, dried at 80°C, and ground into a powdery precursor; the precursor was calcined at 400°C for 4 h to obtain the product. It has been detected that the molar ratio of Co, Ni and O in the product is CoNiO 2.33 / SiO 2 , the loading of active components of double metal oxides is 15%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com