Anode material for alkaline zinc-manganese dry battery and alkaline zinc-manganese dry battery

A zinc-manganese dry battery and positive electrode material technology, which is applied to the electrodes of primary batteries, battery electrodes, electrode carriers/collectors, etc., can solve problems such as personal injury and property, failure to open normally, battery explosion, etc. The effect of reducing the boundary resistance and reducing the contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038]Therefore, preferably, the method for preparing the positive electrode material of the alkaline zinc-manganese dry battery includes the following steps:

[0039]Mix the electrolytic manganese dioxide and barium titanate uniformly. After ball milling in a ball mill, they are then mixed with the positive electrode conductive material, binder, and potassium hydroxide aqueous solution. After uniform mixing, they are pressed, granulated and sieved in sequence. Immediately.

[0040]In order to facilitate the mutual embedding of manganese dioxide crystals and barium titanate crystals, the present invention controls the ball-to-material ratio of ball milling to be 5-25:1, the rotating speed is 120-200rpm, and the ball-to-material ratio is 0.5-2.5h; It is the ratio of the mass of the grinding body and the material in the ball mill.

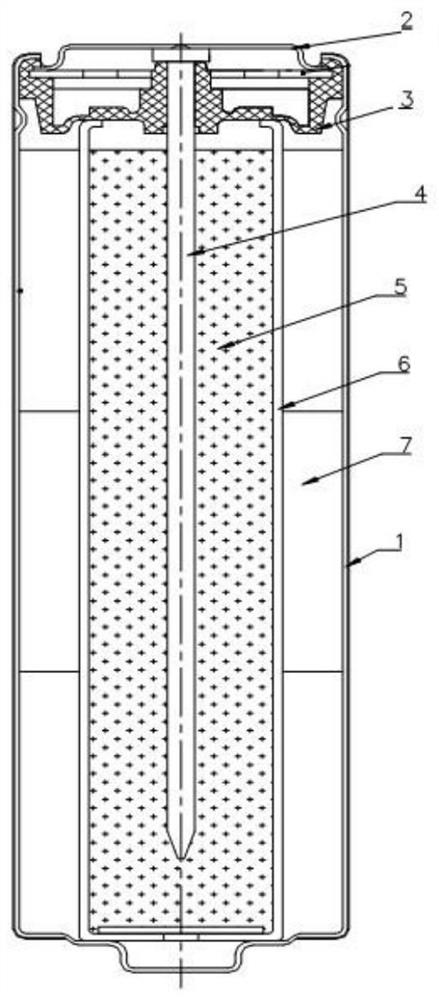

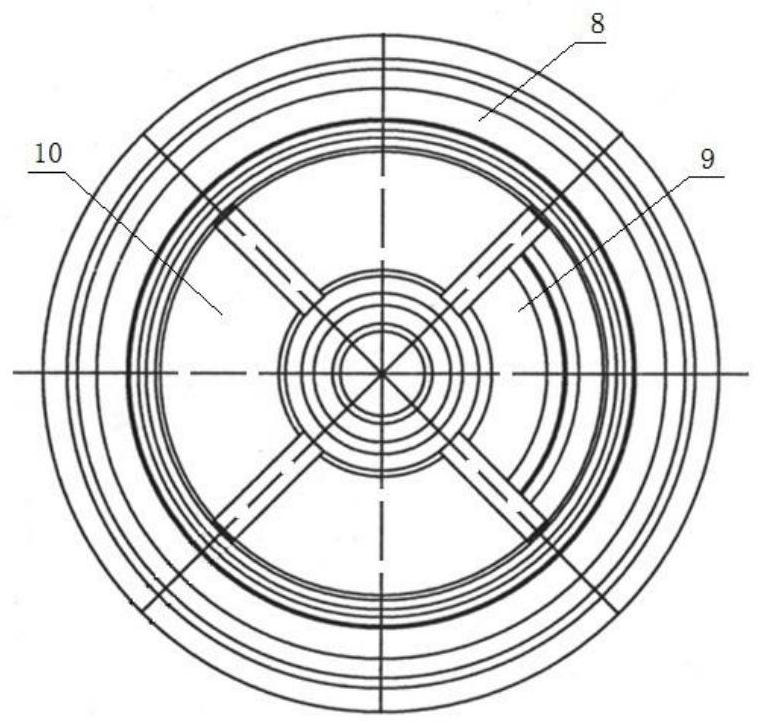

[0041]Using the positive electrode material of the alkaline zinc-manganese dry battery provided by the invention to prepare the alkaline zinc-manganese dry battery...

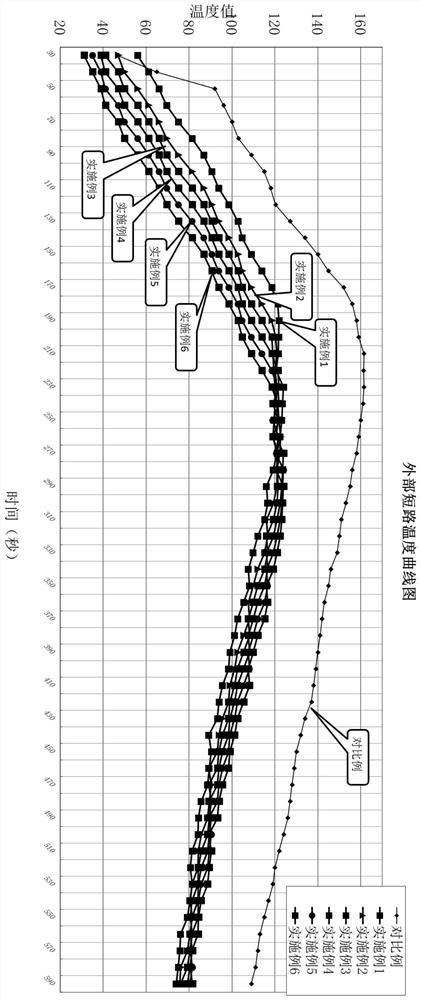

Embodiment 1

[0060]The preparation of the alkaline zinc-manganese dry battery in this embodiment includes the following steps:

[0061]A. After fully mixing 160 parts by mass of the positive electrode active material electrolytic manganese dioxide and 0.02 parts by mass of barium titanate, add them to the ball mill for ball milling, and control the ball-to-battery ratio of the ball mill to 15:1 and the speed to be 180rpm. The ball milling time is 1h; the ball milled mixture is taken out and mixed with 10 parts by mass of positive electrode conductive material graphite, 0.9 parts by mass of adhesive (HA1681), 4 parts by mass of potassium hydroxide aqueous solution (mass concentration of 40%) Fully mix in the mixer, and after uniform mixing, press tablets, granulate and sieving in sequence to prepare the positive electrode material of the alkaline zinc manganese dry battery, and press the positive electrode material into the positive electrode ring 7;

[0062]B. Insert the positive electrode ring 7 into...

Embodiment 2

[0065]The alkaline zinc-manganese dry battery of this embodiment, except in step A, the positive electrode active material electrolytic manganese dioxide, the positive electrode conductive material graphite, the binder (HA1681), the potassium hydroxide aqueous solution (the mass concentration is 40%), and the barium titanate by mass The ratio was 160:10:0.9:4:0.18, and it was prepared by the same method as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com