Composite solid electrolyte and lithium ion battery comprising same

A solid electrolyte, lithium ion battery technology, applied in the field of lithium ion batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045]

[0046] As mentioned above, the present invention provides a composite solid-state electrolyte, and here also provides a preparation method of the above-mentioned composite solid-state electrolyte. The preparation method includes the following steps:

[0047] The oxide solid electrolyte, sintering aid, halide and solvent are mixed and sintered to prepare the composite solid electrolyte.

[0048] According to an embodiment of the present invention, the solvent is selected from at least one of deionized water, methanol, ethanol, tetrahydrofuran, dimethyl sulfoxide, acetone, and acetic acid.

[0049] According to an embodiment of the present invention, the halide is defined as above.

[0050] According to the embodiment of the present invention, the definition of the sintering aid is as described above.

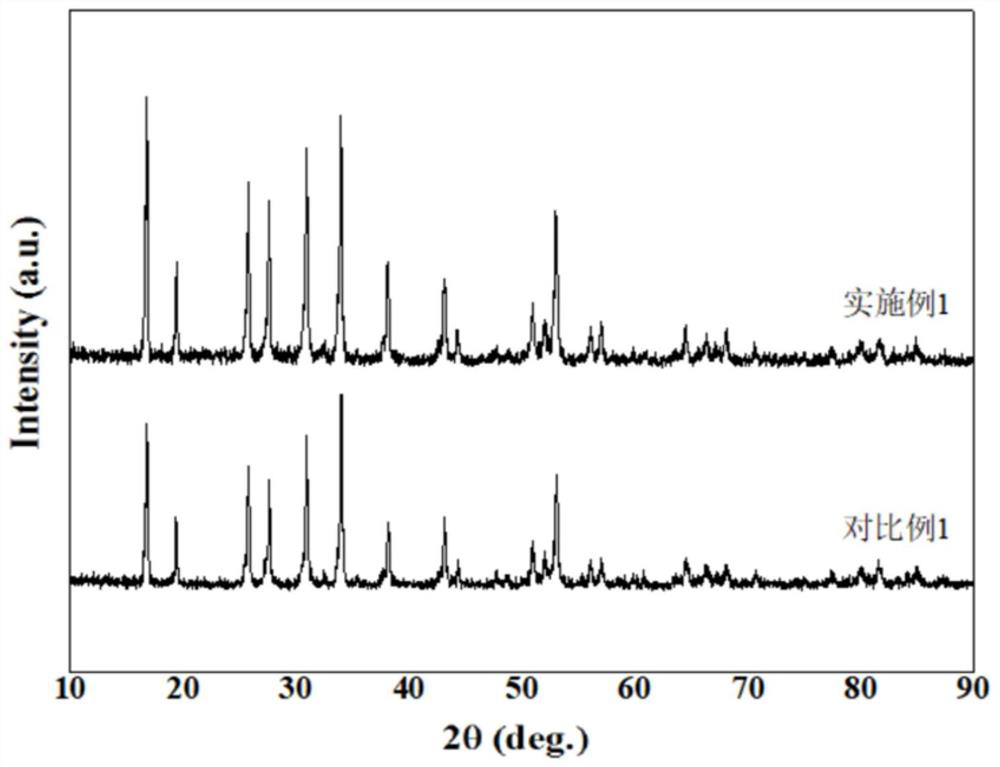

[0051] According to an embodiment of the present invention, the oxide solid state electrolyte is a pure phase without the presence of impurity phases.

[0052] Accor...

Embodiment approach

[0055] According to an embodiment of the present invention, the method specifically includes the following steps:

[0056] Mixing oxide solid electrolyte powder, sintering aid, halide and solvent, cold pressing into a sheet, and then sintering to prepare the composite solid electrolyte;

[0057] Alternatively, the oxide solid electrolyte powder and the sintering aid are cold-pressed into sheets, infiltrated into a precursor solution formed by a halide and a solvent, and then sintered to prepare the composite solid electrolyte;

[0058] Alternatively, the oxide solid electrolyte powder is cold-pressed into sheets, soaked in a precursor solution formed by a sintering aid, a halide and a solvent, and then sintered to prepare the composite solid electrolyte.

[0059] Wherein, the pressure of the cold pressing into a sheet is 1-20 MPa.

[0060] Wherein, the mass fraction of the halide in the precursor solution is 1-30 wt%, and the mass fraction of the sintering aid in the precurso...

Embodiment 1

[0088] (1) Preparation of composite solid electrolyte

[0089] For oxide solid electrolyte powder Li 6.6 La 3 Zr 1.6 Ta 0.4 O 12 Drying; dissolving ammonium fluoride in deionized water at a ratio of 16 wt%, and fully stirring at a speed of 200 rpm for 8h to a homogeneous solution;

[0090] Will Li 6.6 La 3 Zr 1.6 Ta 0.4 O 12 The powder, lithium phosphate and ammonium fluoride aqueous solution were thoroughly mixed uniformly in a mass ratio of 87:1:12, then put into a powder tableting die, and pressed under an axial pressure of 8 MPa to form an electrolyte tablet with a thickness of about 200 μm, which was taken out. The electrolyte sheet was allowed to stand for 30 minutes, sintered at 850° C. for 3 hours and then cooled to obtain a composite solid electrolyte, wherein the composite solid electrolyte included oxide solid electrolyte, lithium phosphate and lithium fluoride, and the oxide solid electrolyte accounted for the 96.7 wt % of the total mass of the composite ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| impedance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com