High-capacity all-solid-state battery and preparation method thereof

An all-solid-state battery, high-capacity technology, used in lithium batteries, secondary batteries, non-aqueous electrolyte batteries, etc., can solve problems such as increasing the difficulty of manufacturing, poor wettability of metal lithium, and increasing manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A large-capacity all-solid-state battery, including a positive electrode, a solid electrolyte, and a negative electrode, without electrolyte and diaphragm; its preparation method is as follows:

[0023] According to the mass ratio of 80:5:5:10, the lithium compound LFP, the conductive agent Super P, the binder PVDF, and the ion conductive agent are mixed, NMP is added to form a slurry, and then coated on the surface of the aluminum foil, and then dried and rolled , to obtain a positive electrode with a thickness of 150 μm;

[0024] According to the weight ratio of PEO, LATP, LAGP is 3:3.5:3.5, and the molar ratio of EO / Li is 14:1, mix PEO, LATP, LAGP, lithium salt LiTFSI, then add acetonitrile to get a slurry, and then coat Put the side of the positive electrode with the lithium compound, and then dry (75°C) to obtain a positive electrode, solid electrolyte (50μm) integrated sheet;

[0025] In the glove box, put a lithium foil on the surface of the solid electrolyte of...

Embodiment 2

[0027] Put lithium foil on the surface of the solid electrolyte of the positive electrode and solid electrolyte integrated sheet in Example 1, then seal it with aluminum-plastic film and lead out the positive and negative electrodes, then pump air, and finally heat press at 55°C for 1 minute to obtain a soft package with a large capacity. Solid-state batteries do not need to add electrolyte or separator between layers.

Embodiment 3

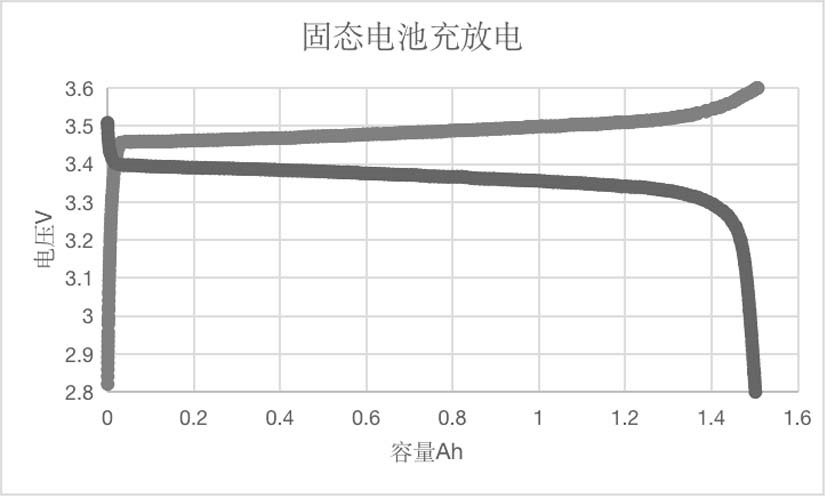

[0029] The positive electrode solid electrolyte integrated sheet and lithium foil of Example 1 are stacked at intervals (the solid electrolyte is in contact with the lithium foil, which is a conventional structure) to form a multi-layer structure, in which the integrated sheet and lithium foil have fifteen layers each, and then aluminum-plastic film Seal the package and lead out the positive and negative electrodes, then pump air, and finally heat press at 60°C for 90 seconds to obtain a soft-packed large-capacity all-solid-state battery. There is no need to add electrolyte or separator between layers. The actual picture is shown in figure 1 (Length and width dimensions are 115*103mm), charge and discharge curve see figure 2 , it can be seen that the positive electrode and electrolyte of the present invention are combined with metal lithium to form a battery, which can have an excellent charge and discharge curve, a lower charging platform and a higher discharging platform, fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com