Electrochemical device and electronic equipment

An electrochemical and electrolyte technology, applied in electrochemical generators, electrolyte immobilization/gelation, circuits, etc., can solve problems such as poor physical contact, large grain boundary resistance, and poor interface stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0084] The above-mentioned positive electrode sheet and negative electrode sheet can be prepared by the commonly used positive electrode sheet and negative electrode sheet preparation methods in the art, which will not be repeated here.

[0085] The lithium ion battery of the present invention can be assembled into a button battery, a mold battery or a pouch battery.

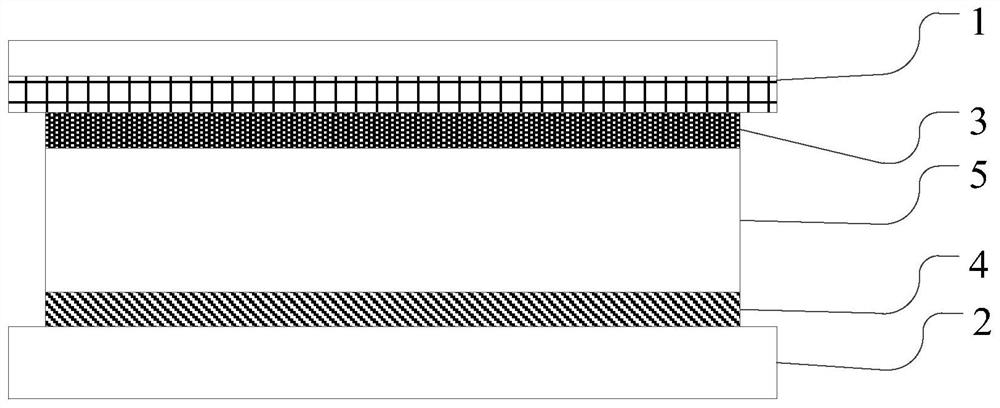

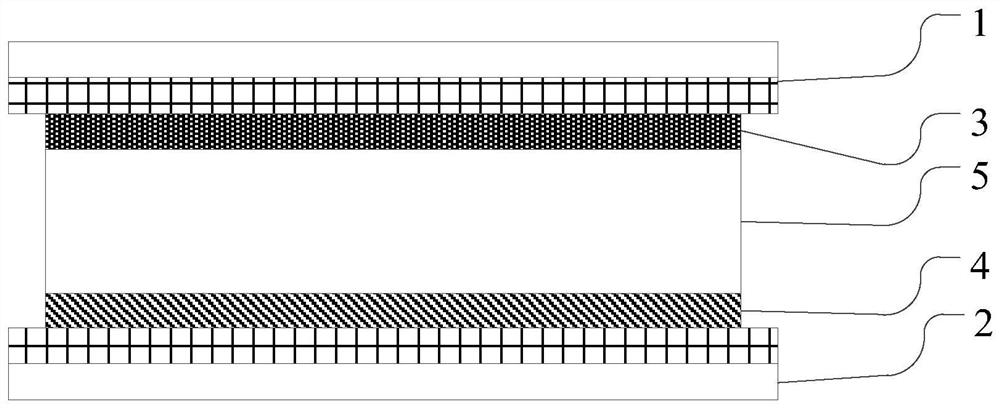

[0086] Wherein, the pouch battery can be manufactured by common winding and stacking processes, and the method commonly used in the field for manufacturing pouch batteries can be used. Specifically, the positive electrode sheet, the electrolyte, and the negative electrode sheet are stacked in sequence, and the stacked cells are vacuum-packaged to obtain a lithium-ion battery with a stacked sheet structure. Alternatively, the laminated positive electrode sheet, electrolyte, and negative electrode sheet are wound, and the wound cell is vacuum-packaged to obtain a lithium-ion battery with a wound structure.

[008...

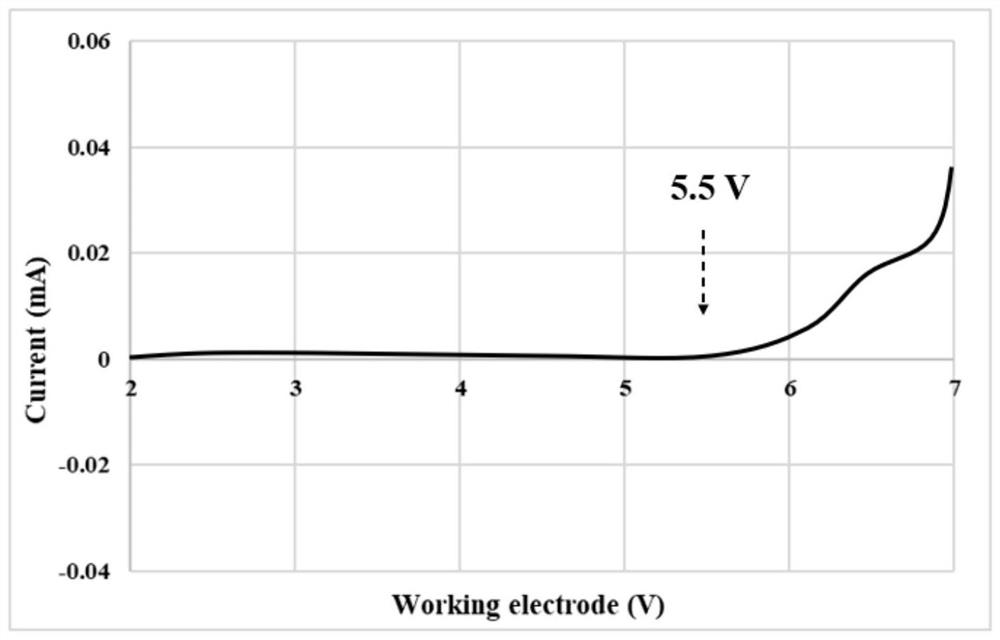

Embodiment 1

[0092] 1) Self-prepared oxide electrolyte powder Li according to the traditional solid-state sintering method 1.5 Al 0.5 Ti 1.5 (PO 4 ) 3 , and it is fully dried and set aside;

[0093] 2) Put the dried electrolyte powder into a mold and press it into a thin sheet, then sinter at 900°C for 6 hours, and then cool in the furnace to obtain an inorganic solid electrolyte layer, the thickness of which is 100 μm;

[0094] 3) methyl methacrylate (MMA), lithium hexafluorophosphate (LiPF 6 ), ethylene carbonate (EC), ethylene glycol dimethyl ether (DME), and benzoyl peroxide are mixed according to a mass ratio of 8:10:45:40:2, and stirred evenly at a speed of 600rpm to obtain nearly Electrolyte precursor on the positive electrode side;

[0095] 4) in Li 1.5 Al 0.5 Ti 1.5 (PO 4 ) 3One surface of the inorganic solid electrolyte layer is coated with the electrolyte precursor near the positive side obtained in step 3), and the prepared lithium iron phosphate positive electrode s...

Embodiment 2

[0101] 1) For commercially purchased oxide electrolyte powder Li 3x La 2 / 3-x TiO 3 (x=0.11) carry out sufficient drying, standby;

[0102] 2) Put the dried electrolyte powder into a mold and press it into a thin sheet, then sinter at 950°C for 4 hours, and then cool in the furnace to obtain an inorganic solid electrolyte layer, the thickness of which is 315 μm;

[0103] 3) Pentaerythritol tetraacrylate, 4,5-dicyano-2-trifluoromethylimidazolium lithium (LiDTI), diethyl carbonate (DEC), azobisisobutyronitrile according to 6:15:88: Mix at a mass ratio of 1, and stir evenly at a speed of 400rpm to obtain the electrolyte precursor near the positive side;

[0104] 4) in Li 3x La 2 / 3-x TiO 3 (x=0.11) one surface coating step 3) of the inorganic solid electrolyte layer obtains near positive electrode side electrolyte precursor solution, the prepared LiNi 0.5 co 0.3 mn 0.2 o 2 The positive electrode sheet is covered on the electrolyte precursor near the positive electrode, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Areal density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com