Sulfide composite solid-state electrolyte membrane, preparation method thereof and solid-state battery

A technology of solid electrolyte membrane and solid electrolyte, which is applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, battery electrodes, etc., can solve problems such as the inability to prepare large-area sulfide solid electrolyte membranes, achieve good chemical compatibility, reduce crystal The effects of boundary impedance and high ionic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

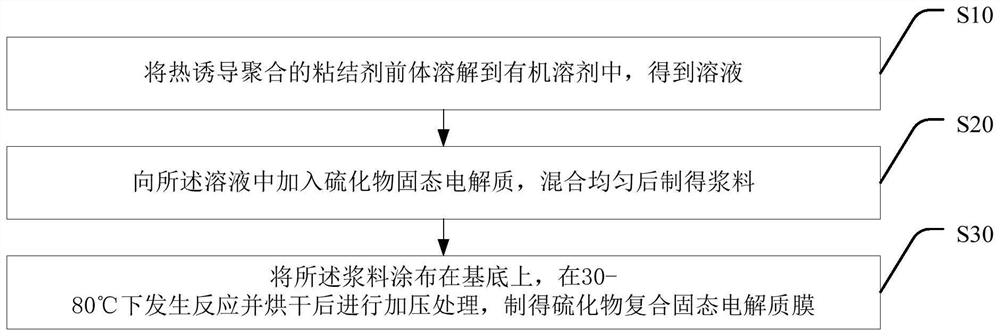

Method used

Image

Examples

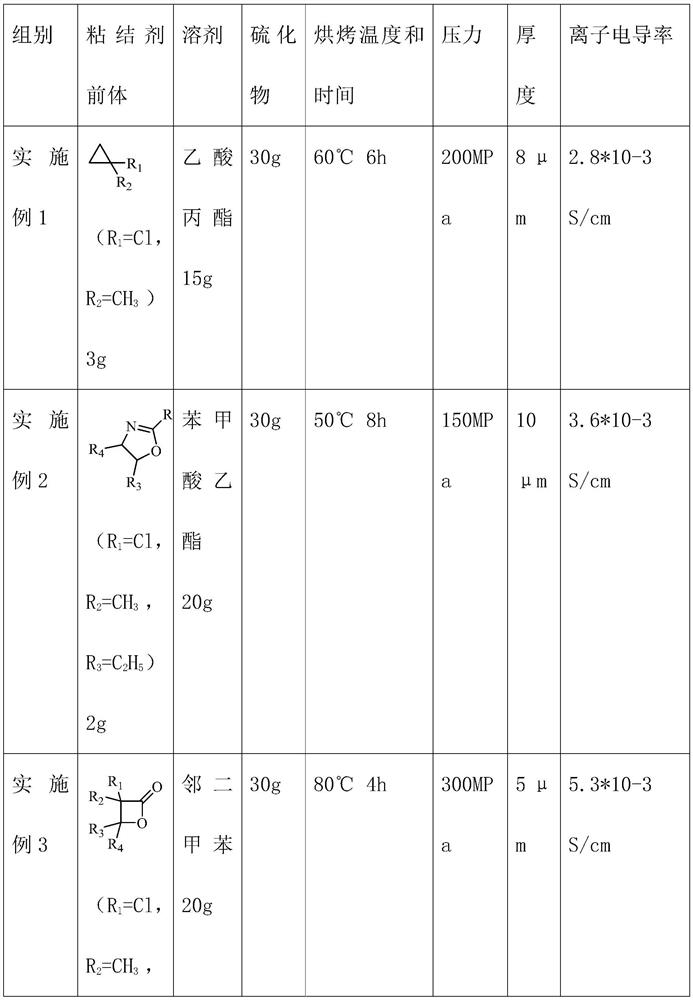

Embodiment 1

[0038] Weigh 3g where R 1 =Cl, R 2 =CH 3 Dissolve in 15g propyl acetate and disperse evenly, then add 30g sulfide and stir evenly to obtain a mixed slurry. The above slurry is evenly spin-coated on the substrate, baked at 60°C for 6h, pressurized at 200MPa, and peeled off to obtain The composite solid electrolyte membrane with a thickness of 8 μm has a tested conductivity of 2.8*10 -3 S / cm.

Embodiment 2

[0040] Weigh 2g where R 1 =Cl, R 2 =CH 3 , R 3 =C 2 H 5 Dissolved in 20g of ethyl benzoate and dispersed evenly, then added 30g of sulfide and stirred evenly to obtain a mixed slurry. The above slurry was evenly spin-coated on the substrate, baked at 50°C for 8h, pressurized at 150MPa, and peeled off. A composite solid electrolyte membrane with a thickness of 10 μm was obtained, and the tested conductivity was 3.6*10 -3 S / cm.

Embodiment 3

[0042] Weigh 2g where R 1 =Cl, R 2 =CH 3 , R 3 =C 2 H 5 , R4=OCH 3 Dissolve in 20g o-xylene and disperse evenly, then add 30g sulfide and stir evenly to obtain a mixed slurry. The above slurry is evenly spin-coated on the substrate, baked at 80°C for 4h, pressurized at 300MPa, and peeled off to obtain The composite solid electrolyte membrane with a thickness of 5μm has a tested conductivity of 5.3*10 -3 S / cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com