Mg-Bi-based lamellar block crystal material and growth method thereof

A technology of crystal materials and growth methods, applied in the growth of polycrystalline materials, crystal growth, single crystal growth, etc., can solve the problems of inability to obtain high-quality bulk crystal materials, difficulty in growth amplification, high growth costs, etc., and achieve repeated use. High efficiency, uniform distribution of constituent elements, improved crystal quality and growth efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

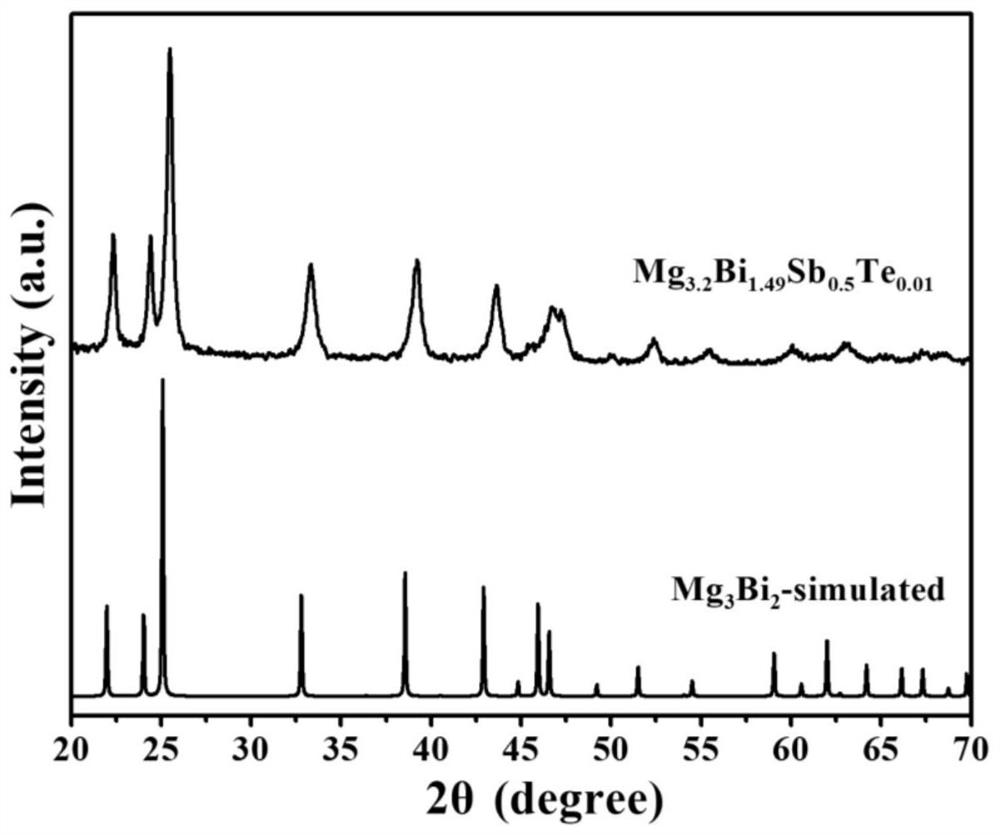

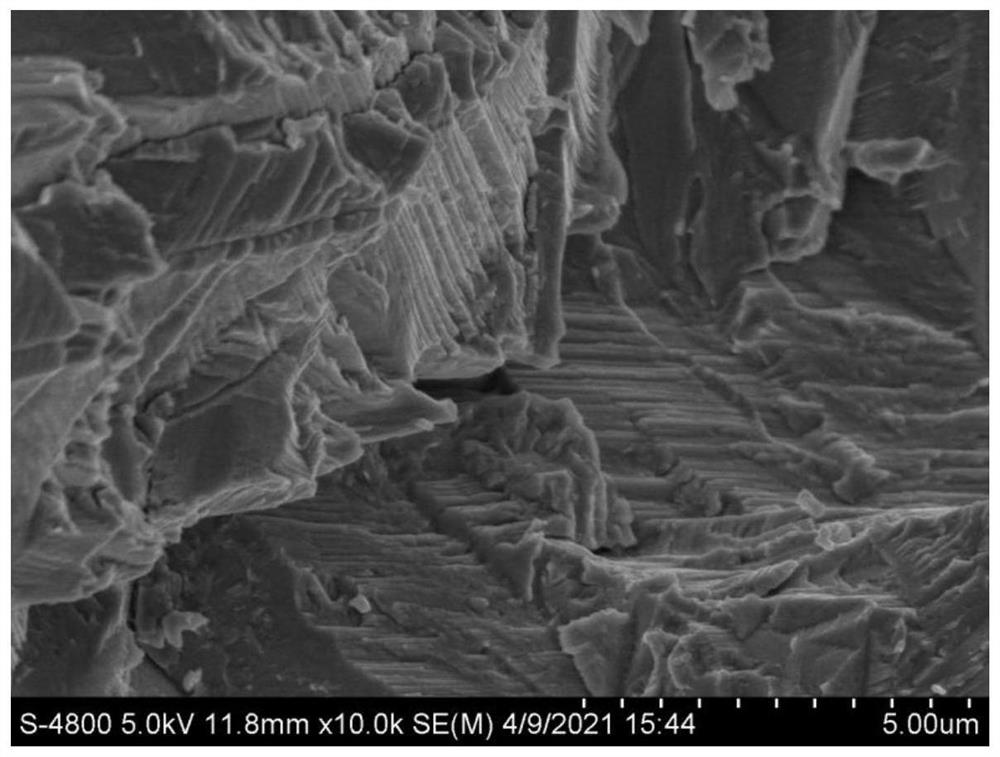

[0051] Example 1: Mg 3.2 Bi 1.49 Sb 0.5 Te 0.01 Preparation of Layered Bulk Polycrystalline Materials

[0052] (1) In the glove box of Ar gas atmosphere, press Mg 3.2 Bi 1.49 Sb 0.5 Te 0.01 The stoichiometric ratio of each atom, the single substance raw material of each element is weighed in the Ta crucible; another graphite crucible is placed upside down on the Ta crucible, and the graphite crucible and the Ta crucible are placed opposite to each other, and the above two crucibles are protected under the Ar atmosphere. Raise the temperature to 1000°C to fully react and melt the raw materials, and then quench to obtain a polycrystalline ingot tightly adhered to the Ta crucible.

[0053] (2) Exchange the positions of the Ta crucible and the graphite crucible in step (1), so that the Ta crucible is located above the graphite crucible, put it into the descending furnace, and raise the temperature to 1000 ° C under the protection of Ar atmosphere, that is, the temperature o...

Embodiment 2

[0056] Example 2: Mg 3.2 Bi 1.49 Sb 0.5 Te 0.01 Preparation of Layered Bulk Single Crystal Materials

[0057] (1) In the glove box of Ar gas atmosphere, press Mg 3.2 Bi 1.49 Sb 0.5 Te 0.01 The stoichiometric ratio of each atom, the single substance raw material of each element is weighed in the Ta crucible; another graphite crucible is placed upside down above the Ta crucible, and the graphite crucible and the Ta crucible are placed opposite to each other, and the above two crucibles are placed under the protection of Ar gas atmosphere , the temperature is raised to 1000°C, so that the raw materials are fully reacted and melted, and then quenched to obtain a polycrystalline ingot tightly adhered to the Ta crucible.

[0058](2) Exchange the positions of the Ta crucible and the graphite crucible in step (1), so that the Ta crucible is located above the graphite crucible, put it into the descending furnace, and raise the temperature to 1000 ° C under the protection of Ar a...

Embodiment 3

[0061] Example 3: Mg 3.2 Bi 0.99 SbT 0.01 Preparation of Layered Bulk Polycrystalline Materials

[0062] (1) In the glove box of Ar gas atmosphere, press Mg 3.2 Bi 0.99 SbT 0.01 The stoichiometric ratio of each atom, the single substance raw material of each element is weighed in the Ta crucible; another graphite crucible is placed upside down above the Ta crucible, and the graphite crucible and the Ta crucible are placed opposite to each other, and the above two crucibles are placed under the protection of Ar gas atmosphere , the temperature is raised to 1050°C, so that the raw materials are fully reacted and melted, and then quenched to obtain a polycrystalline ingot tightly adhered to the Ta crucible.

[0063] (2) Exchange the positions of the Ta crucible and the graphite crucible in step (1), so that the Ta crucible is located above the graphite crucible, put it into the descending furnace, and raise the temperature to 1050 ° C under the protection of Ar atmosphere, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com