Construction method of high-fill prefabricated cast-in-situ combined pile slab wall protection structure

A technology for protective structures and construction methods, which is applied in basic structure engineering, underwater structures, artificial islands, etc., can solve the problems of large number of drilling holes and grouting works, insufficient self-stability, slow construction progress, etc. The effect of short construction period, collapse prevention and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and are not limited to the following examples.

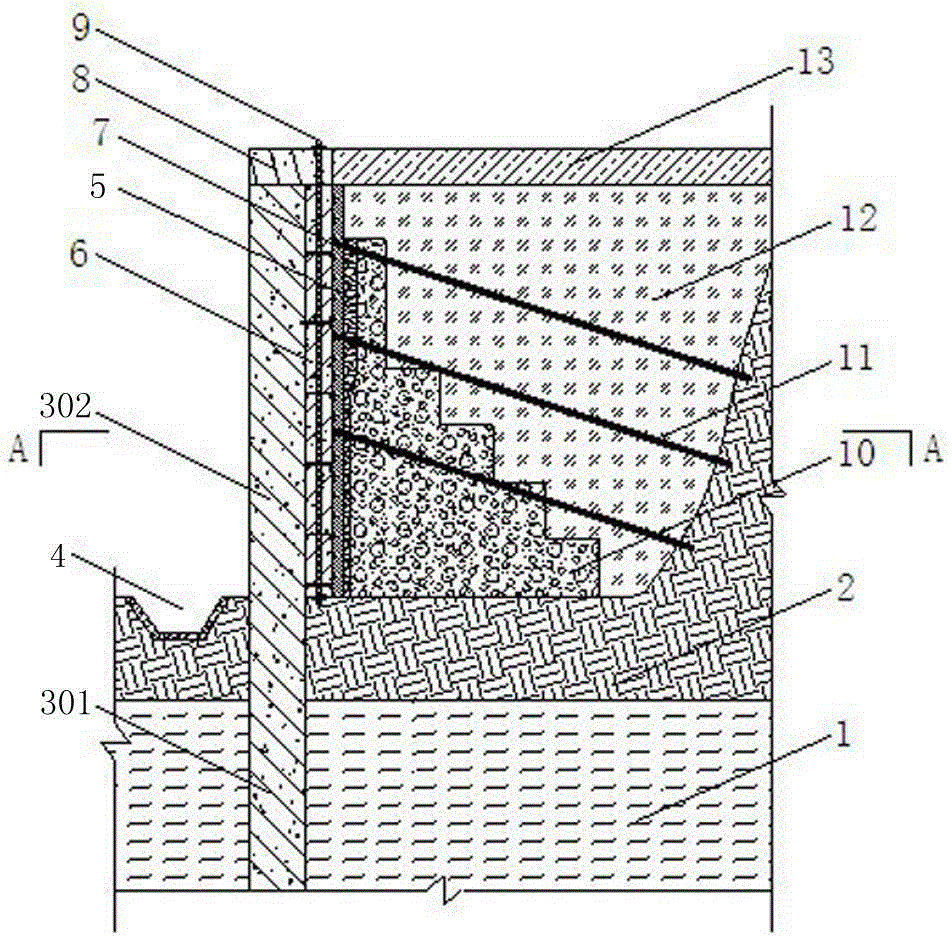

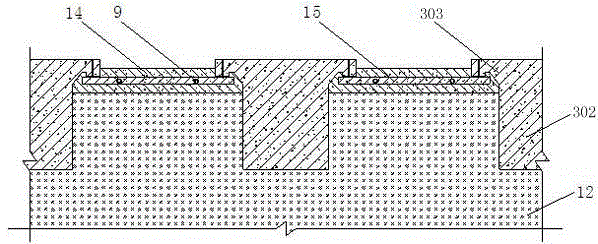

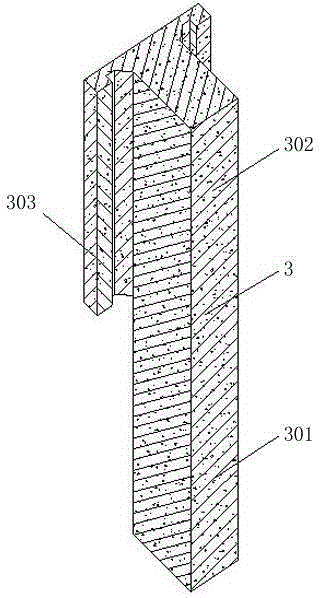

[0039] figure 1 It is a schematic diagram of the high-fill prefabricated cast-in-place combined pile-slab wall protection structure of the present invention, figure 2 It is the construction plan view before the prefabricated soil retaining board 6 of the present invention is not installed, image 3 It is a perspective view of the anti-slide pile in the present invention, Figure 4 It is a perspective view and a schematic connection diagram of a prefabricated earth retaining board in the present invention, Figure 5 It is a perspective view of the cover beam in the present invention, Figure 6 yes figure 1Sectional view along A-A direction.

[0040] refer to Figure 1-6 As shown, the high-fill prefabricated cast-in-place combined ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com