Process for continuously producing trimethyl phosphite by using N, N-dimethylaniline

A technology of trimethyl phosphite and dimethylaniline, applied in the field of trimethyl phosphite preparation, can solve the problems of large environmental pollution, high production cost, large amount of alkali consumption, etc., and achieves a small amount of system solvent and sewage. The effect of low processing cost and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

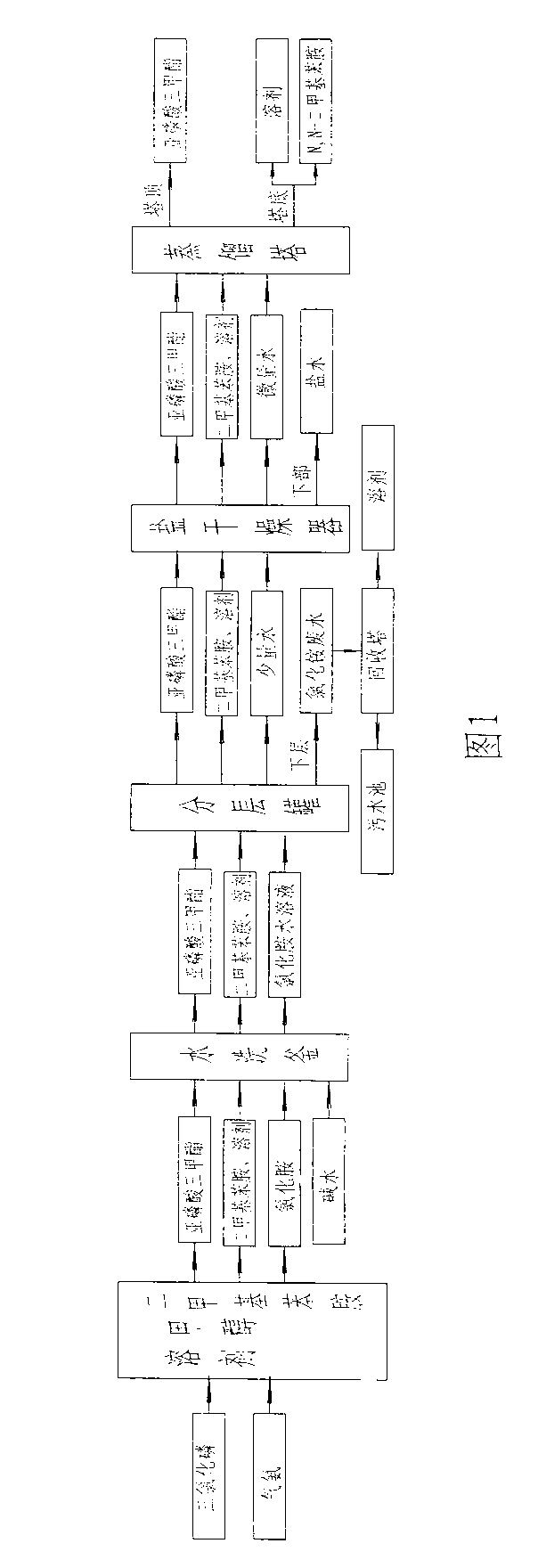

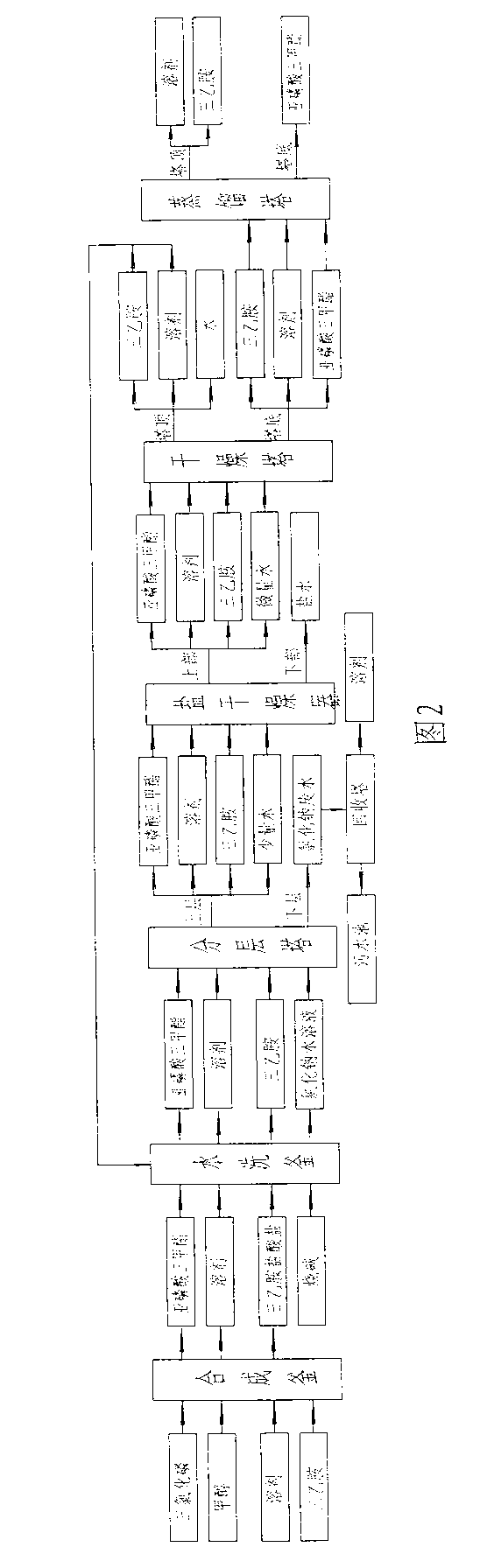

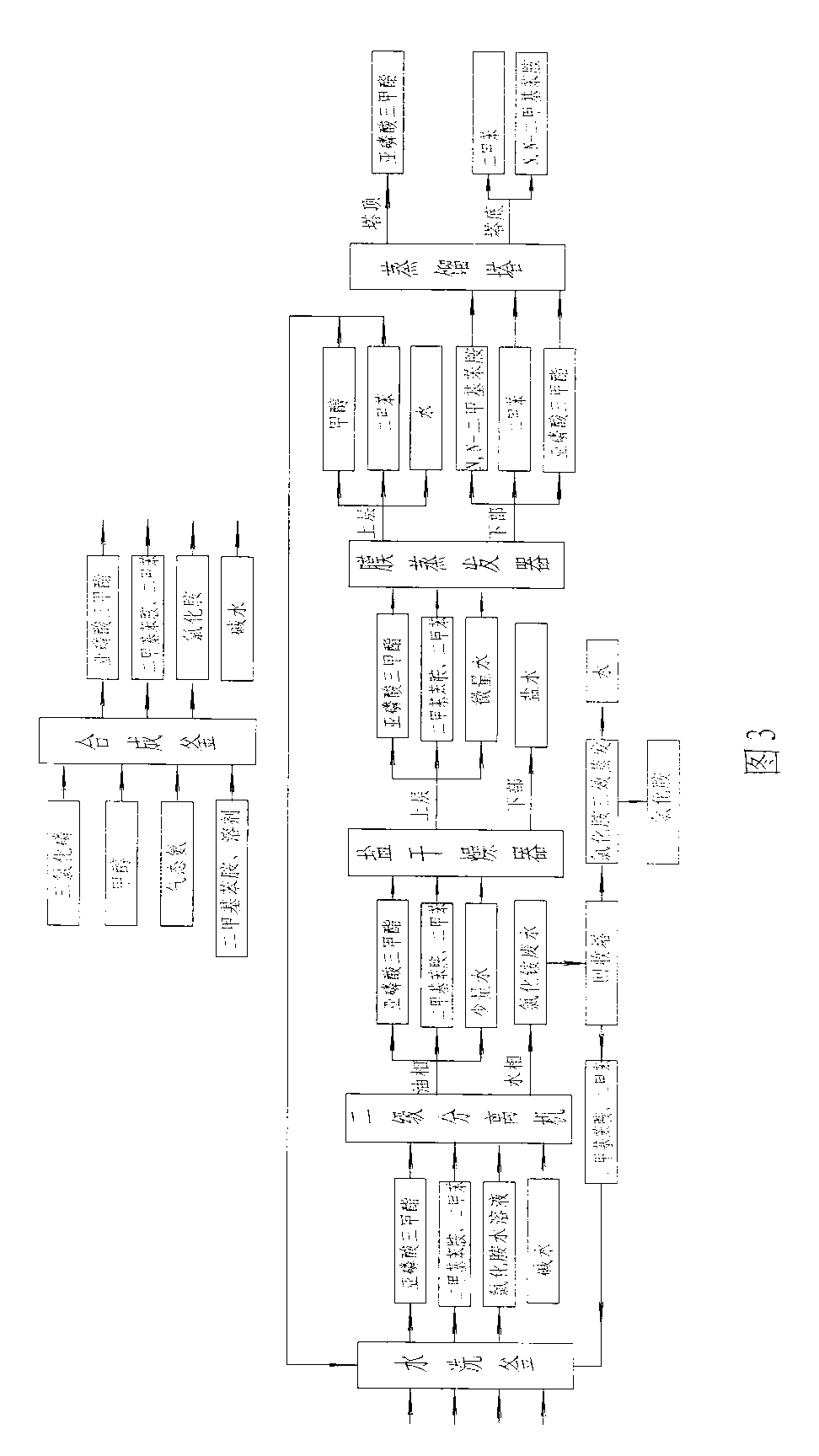

Image

Examples

Embodiment Construction

[0053] The present invention will be further described below by a specific embodiment, take the trimethyl phosphite product of producing 1000Kg as example.

[0054] The raw materials in this embodiment are 1160Kg of phosphorus trichloride, 820Kg of methanol, 450Kg of liquid ammonia, and 1000kg of 6% alkaline water; the produced trimethyl phosphite product is 1000Kg.

[0055] Step 1: Synthesis:

[0056] Weigh 1160Kg of phosphorus trichloride with a content of ≥99.0%, 823.6Kg of methanol with a content of ≥99.5%, 6994.8Kg of xylene, and 3004.4 Kg of N,N-dimethylaniline with a water content of ≤0.05% and put them into a reaction kettle for synthesis. Add gas ammonia 452.4Kg; when inputting, the flow rate of phosphorus trichloride is 10 kg / min; the flow rate of methanol is 7 kg / min; the flow rate of solvent N,N-dimethylaniline and xylene solvent mixture is 100 kg / min min; The gas ammonia flow rate is 4㎏ / min. The material temperature in the reaction kettle is 15-20°C, and the pH ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com