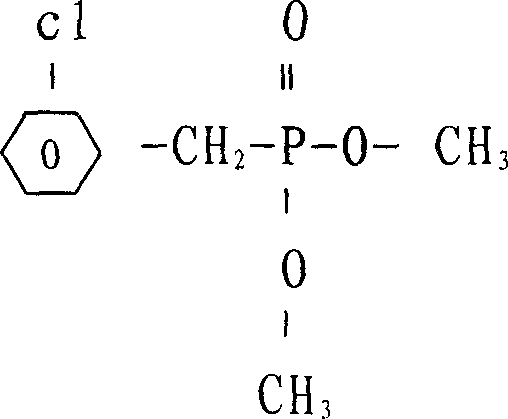

Production of o-chlorobenzyl dimethyl phosphonate

A technology for the production of dimethyl o-chlorobenzylphosphonate, which is applied in the field of preparation of pesticide intermediates, can solve the problems affecting the development and application of new pesticides with high efficiency and low toxicity, the inability to realize the industrial production of epoxiconazole, and the production process of epoxiconazole Complexity and other issues, to achieve the effect of improving yield and performance indicators, easy operation, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Example 1: Take 470kg of o-chlorobenzyl chloride, 270kg of trimethyl phosphite, 250kg of chlorinated benzene, and 10kg of soda ash, and put them into a 1000L reactor and mix them thoroughly. The feed is normal pressure and 20°C; heat the above raw materials to 95 ℃, react at normal pressure for 80h; then collect low-boiling substances (chlorinated benzene as a solvent) under normal pressure. With the decrease of low-boiling substances, the temperature in the kettle will increase, and auxiliary heating can also be carried out to the kettle. When the temperature is 165℃, vacuum up to -0.06Mpa, continue to extract low boilers; then the reactor is evacuated to -0.05MPa, heated to 195℃, and crude distillation is carried out for 8h; then transfer to the kettle, vacuum -0.05MPa, and heat to 220℃, rectify for 8h; finally, the finished product obtained by rectification is filled (in barrels), and the yield of the finished product is more than 1.3 times the weight of o-chlorobenzyl c...

Embodiment 2

[0018] Example 2: Take 1004 kg of o-chlorobenzyl chloride, 500 kg of trimethyl phosphite, 480 kg of chlorinated benzene, and 16 kg of soda ash, and put them into a 2000L reactor and mix them thoroughly. The feed is normal pressure and 22°C; heat the above raw materials to 150 ℃, react under normal pressure for 25h; then collect low-boiling substances (chlorinated benzene as a solvent) under normal pressure, when the temperature in the kettle is 165℃, vacuumize to -0.06Mpa, continue to extract low-boiling substances; The reaction kettle is evacuated to -0.08MPa, heated to 210°C, and crude distillation is carried out for 2h; then transferred to the kettle, evacuated -0.08MPa, heated to 250°C, and rectified for 2h; finally the finished product obtained by the rectification is filled (in barrels) ), the yield of the finished product is more than 1.3 times the weight of o-chlorobenzyl chloride, and then the reaction kettle is restored to normal pressure and reduced to normal temperatur...

Embodiment 3

[0019] Example 3: Take 2090 kg of o-chlorobenzyl chloride, 1450 kg of trimethyl phosphite, 1400 kg of chlorinated benzene, and 60 kg of soda ash, put them into a 5000L reactor, mix them thoroughly, and heat the above raw materials to 120 at normal pressure. ℃, react at normal pressure for 50h; then collect low-boiling substances (chlorinated benzene as a solvent) under normal pressure. When the temperature in the kettle is 165℃, vacuumize to -0.06Mpa and continue to extract low-boiling substances; The reaction kettle is evacuated to -0.06MPa, heated to 200°C, and crude distillation is carried out for 5h; then transferred to the kettle, evacuated -0.06MPa, heated to 230°C, and rectified for 5h; finally the finished product obtained by the rectification is filled (in barrels) ), the yield of the finished product is more than 1.3 times the weight of o-chlorobenzyl chloride, and then the reactor is restored to normal pressure and reduced to normal temperature, and the residue is disch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com