Preparation method of halogen-free retardant dimethyl methylphosphonate

A technology of dimethyl methylphosphonate and flame retardant, which is applied in the field of preparation of halogen-free flame retardant dimethyl methylphosphonate, can solve the problems of high toxicity of methyl iodide, restriction of industrialization, and high cost, and achieve raw material Low cost, easy operation and protection, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

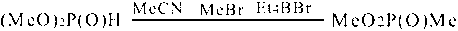

Method used

Image

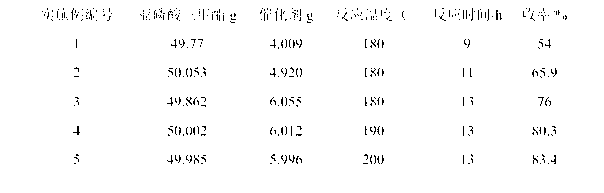

Examples

Embodiment 1

[0025] A preparation method of halogen-free flame retardant methyl methyl phosphonate, it comprises the steps:

[0026] Put the three-necked flask and trimethyl phosphite (TMP) into the refrigerator, treat at 0°C, and then add trimethyl phosphite (TMP) and catalyst p-toluenesulfonate to the three-necked flask under the protection of nitrogen Add 50g and 4g of the two (mass ratio is 100:8), put the three-necked flask in an oil bath, install the stirrer, condenser tube and thermometer, start stirring, and the whole reaction is under the protection of nitrogen conduct;

[0027] Under the condition of stirring, when the temperature is gradually raised to 110°C, reflux begins to appear, and a steady and continuous reflux is maintained for 30 minutes; then the reflux gradually subsides, and then the temperature is gradually raised to 150°C, and a stable and continuous reflux continues, and the temperature is maintained at 150°C , continued for 15 minutes, and after the reflux was c...

Embodiment 2

[0030] A preparation method of halogen-free flame retardant methyl methyl phosphonate, it comprises the steps:

[0031] Put the three-necked flask and trimethyl phosphite (TMP) into the refrigerator, treat at 0°C, and then add trimethyl phosphite (TMP) and catalyst p-toluenesulfonate to the three-necked flask under the protection of nitrogen Add 50g and 5g of methyl ester to the two (mass ratio is 100:10), put the three-necked flask in an oil bath, install the stirrer, condenser and thermometer, start stirring, and the whole reaction is under the protection of nitrogen conduct;

[0032] Under the condition of stirring, when the temperature is gradually raised to 115°C, reflux begins to appear and maintains a stable and continuous reflux for 30 minutes; then the reflux gradually subsides, and then gradually increases the temperature to 150°C, and continues to appear stable and continuous reflux, keeping the temperature at 150°C , continued for 15 minutes, and after the reflux ...

Embodiment 3

[0035] A kind of preparation method of halogen-free flame retardant methyl methyl phosphonate, it comprises the steps:

[0036] Put the three-necked flask and trimethyl phosphite (TMP) into the refrigerator, treat at 0°C, and then add trimethyl phosphite (TMP) and catalyst p-toluenesulfonate to the three-necked flask under the protection of nitrogen Add 50g and 6g respectively of the two, (mass ratio is 100:12), put the three-necked flask in an oil bath, install the stirrer, condenser tube and thermometer, start stirring, and the whole reaction is under the protection of nitrogen under;

[0037] Under the condition of stirring, when the temperature is gradually raised to 120°C, reflux begins to appear and maintains a stable and continuous reflux for 30 minutes; then the reflux gradually subsides, and then gradually increases the temperature to 150°C, and then continues to appear stable and continuous reflux, keeping the temperature at 150°C , continued for 15 minutes, and aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com