Multi-metal recycling method of electric furnace tin-smelting dust

A recovery method and multi-metal technology, which can be applied in the direction of improving process efficiency, can solve problems such as difficulty in separation, and achieve the effects of smooth process, improved leaching rate, and efficient extraction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

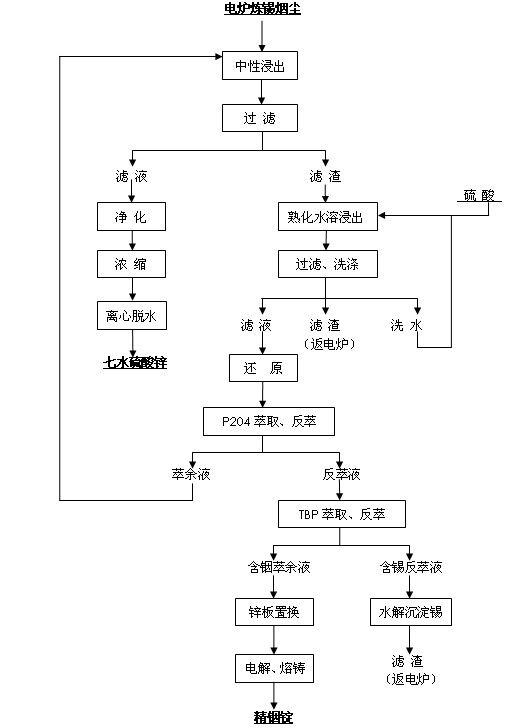

Image

Examples

Embodiment Construction

[0019] Taking a batch of electric furnace tin fume produced by a tin smelting enterprise in Gejiu City, Honghe Prefecture, Yunnan Province as an example, its material composition is: Sn 12.24%, Zn 41.62%, Pb 7.59%, In 4413g / t, H 2 O 2.5%, the balance is other components.

[0020] As shown in the attached picture. Raffinate extracted with indium (H 2 SO 4 100g / L) for neutral leaching of the above-mentioned dust (in the initial stage, adding sulfuric acid leaching when there is no extracting solution) to control the pH of the leaching end point to 5-5.4, so that more than 60% of zinc can be leached into the solution, and tin, indium, and lead remain in the neutral leaching residue.

[0021] The zinc-containing leaching solution is oxidized by air to remove iron and arsenic, and zinc powder is added to replace and remove Cd, adsorbed by activated carbon, and concentrated to obtain industrial-grade zinc sulfate heptahydrate.

[0022] The neutral leaching slag is matured and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com