Method for preparing beancurd preserved flavour product

A production method and technology of fermented bean curd, which is applied in the field of food production and fermented bean curd food production, and achieves the effects of prominent and obvious effects, simple and applicable method, and easy to carry and eat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

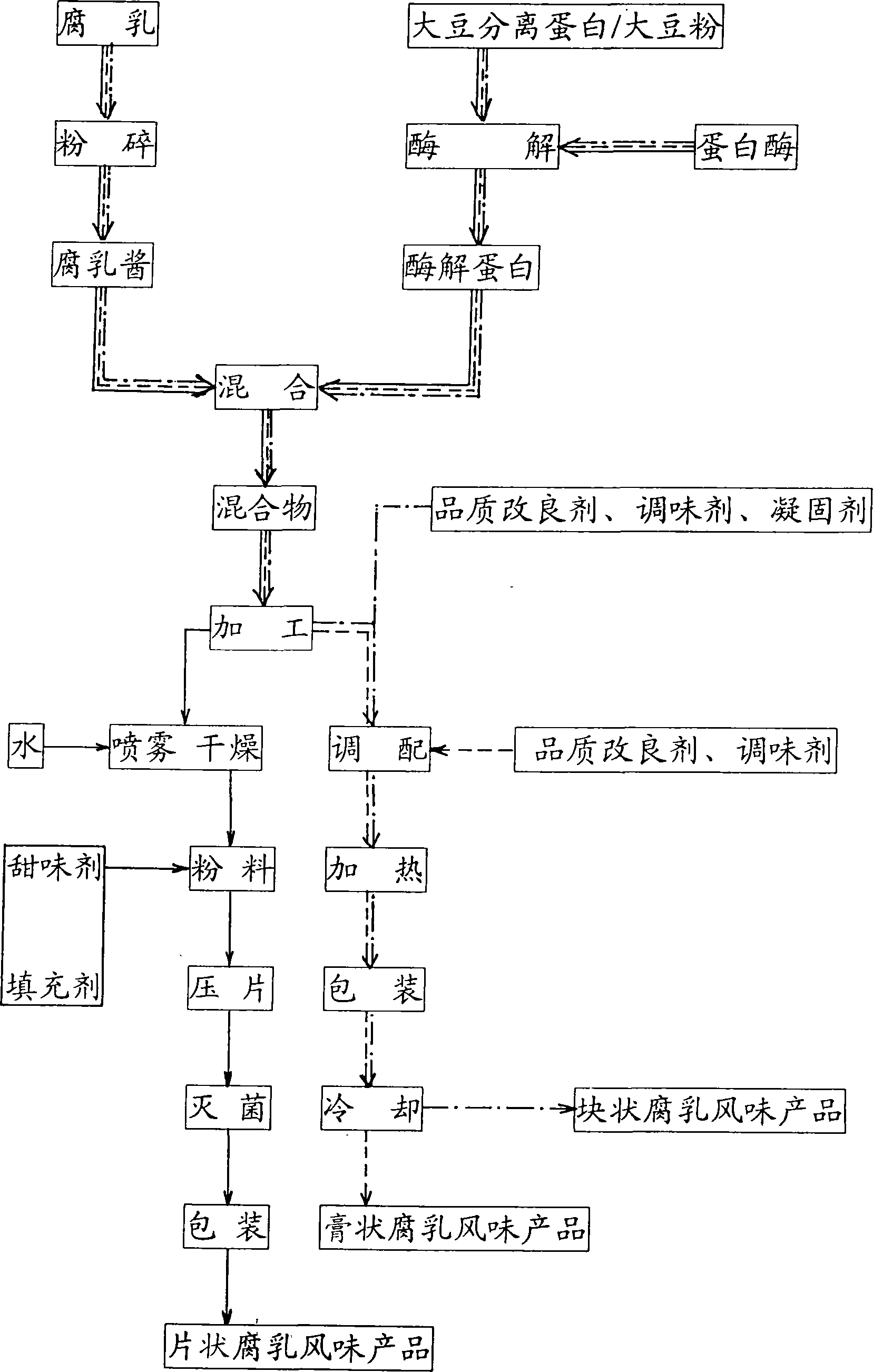

Method used

Image

Examples

specific Embodiment approach 2

[0058] Carry out by specific implementation mode one, just:

[0059] 120kg fermented bean curd paste, 350kg hydrolyzed protein with a water content of 82%, sucrose / xylitol / maltitol / aspartame / sucralose / isomaltitol / erythritol / lactitol / mannose Alcohol sweetener is 11 kg, pregelatinized starch / carboxymethyl cellulose / maltooligosaccharide / starch filler is 27 kg, carrageenan / xanthan gum / sodium alginate / agar / gum arabic / locust bean gum / Guar gum / sodium pyrophosphate / sodium citrate / sodium hexametaphosphate / compound phosphate / konjac powder quality improver is 0.2 kg, sucrose / xylitol / maltitol / aspartame / sucralose / Isomalt / erythritol / lactitol / mannitol / seafood extract / pork or chicken or beef powder / water-soluble spicy powder / coconut milk powder / garlic powder / ginger powder / butter or edible vegetable oil flavoring is 6 kilograms, 3 kilograms of magnesium chloride / calcium carbonate coagulation salt, the moisture after mixing is 73%, then heated to 91 DEG C for 12 minutes, and naturally cooled...

specific Embodiment approach 3

[0060] Carry out by specific implementation mode one, just:

[0061] 140 kg of bean curd paste, 300 kg of hydrolyzed protein with a water content of 84%, sucrose / xylitol / maltitol / aspartame / sucralose / isomaltitol / erythritol / lactitol / mannose Alcohol sweetener is 12 kg, pregelatinized starch / carboxymethyl cellulose / malt-oligosaccharide / starch filler is 26 kg, carrageenan / xanthan gum / sodium alginate / agar / gum arabic / locust bean gum / Guar gum / sodium pyrophosphate / sodium citrate / sodium hexametaphosphate / compound phosphate / konjac powder quality improver is 0.3 kg, sucrose / xylitol / maltitol / aspartame / sucralose / Isomalt / erythritol / lactitol / mannitol / seafood extract / pork or chicken or beef powder / water-soluble spicy powder / coconut milk powder / garlic powder / ginger powder / butter or edible vegetable oil flavoring is 4 kilograms, 4 kilograms of magnesium chloride / calcium carbonate solidified salt, the moisture after mixing is 74%, then heated to 92 DEG C for 14 minutes, and naturally cooled to...

specific Embodiment approach 4

[0062] Carry out by specific implementation mode one, just:

[0063] 160 kg of fermented bean curd paste, 250 kg of hydrolyzed protein with a water content of 86%, sucrose / xylitol / maltitol / aspartame / sucralose / isomaltitol / erythritol / lactitol / mannose Alcohol sweetener is 13 kg, pregelatinized starch / carboxymethyl cellulose / maltooligosaccharide / starch filler is 25 kg, carrageenan / xanthan gum / sodium alginate / agar / gum arabic / locust bean gum / Guar gum / sodium pyrophosphate / sodium citrate / sodium hexametaphosphate / compound phosphate / konjac powder quality improver is 0.4 kg, sucrose / xylitol / maltitol / aspartame / sucralose / Isomalt / erythritol / lactitol / mannitol / seafood extract / pork or chicken or beef powder / water-soluble spicy powder / coconut milk powder / garlic powder / ginger powder / butter or edible vegetable oil flavoring is 2 kilograms, 5 kilograms of magnesium chloride / calcium carbonate coagulation salt, the moisture after mixing deployment is 75%, then heated to 93 DEG C for 16 minutes, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com