Method for reducing salt content in preserved beancurd

A technology of salt content and fermented bean curd, which is applied in the field of food production, salt content of fermented bean curd, and fermented bean curd food production, can solve the problems of unfavorable production development and improvement, slow change of fermented bean curd process, and influence on the intake of fermented bean curd, so as to enrich people life, increase the intake of fermented bean curd, and ensure the effect of healthy diet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

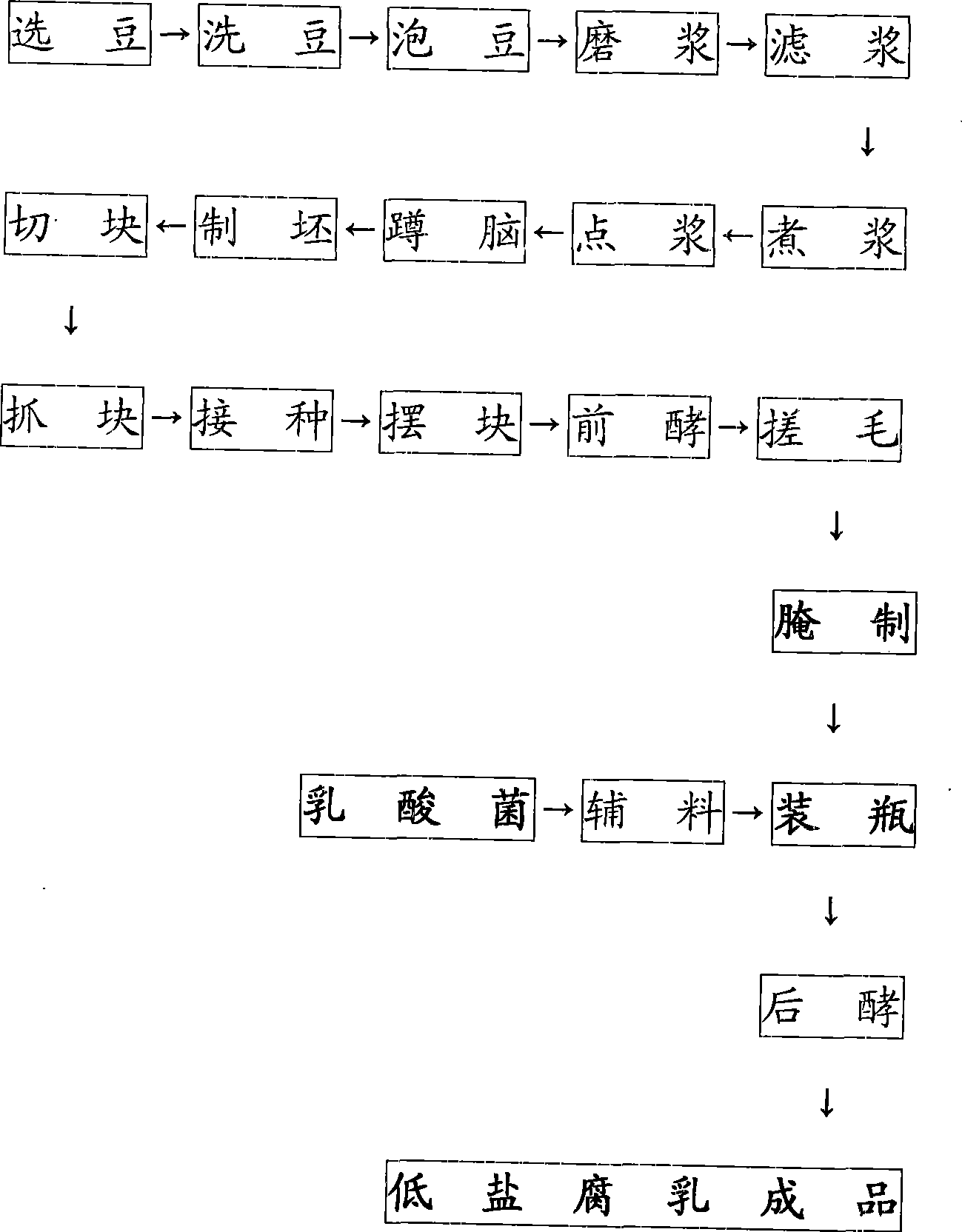

[0029] Below in conjunction with accompanying drawing of description, the method for reducing the salt content of fermented bean curd of the present invention is described in detail, as shown in accompanying drawing of description:

[0030] A method for reducing the salt content of fermented bean curd, including selecting beans, washing beans, soaking beans, grinding, filtering, boiling, pointing, squatting, making blanks, cutting into pieces, grasping pieces, inoculating, placing pieces, and the early stage The production process of fermenting, rubbing, pickling, bottling, adding auxiliary materials, and post-fermentation to obtain low-salt fermented bean curd products; its main technical characteristics are as follows:

[0031] (1), the pickling: in the pickling process, the amount of salt added is controlled; that is, the amount of salt added is less than three-quarters of the conventional amount of salt added;

[0032] (2), described bottling and add auxiliary material:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com