On-line changing method of hot blast main duct of blast furnace

A technology of hot air main pipe and replacement method, applied in blast furnace, blast furnace details, blast furnace parts and other directions, can solve problems such as refractory brick damage, large owner loss, shell deformation, etc., saving construction period and cost, small production impact, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

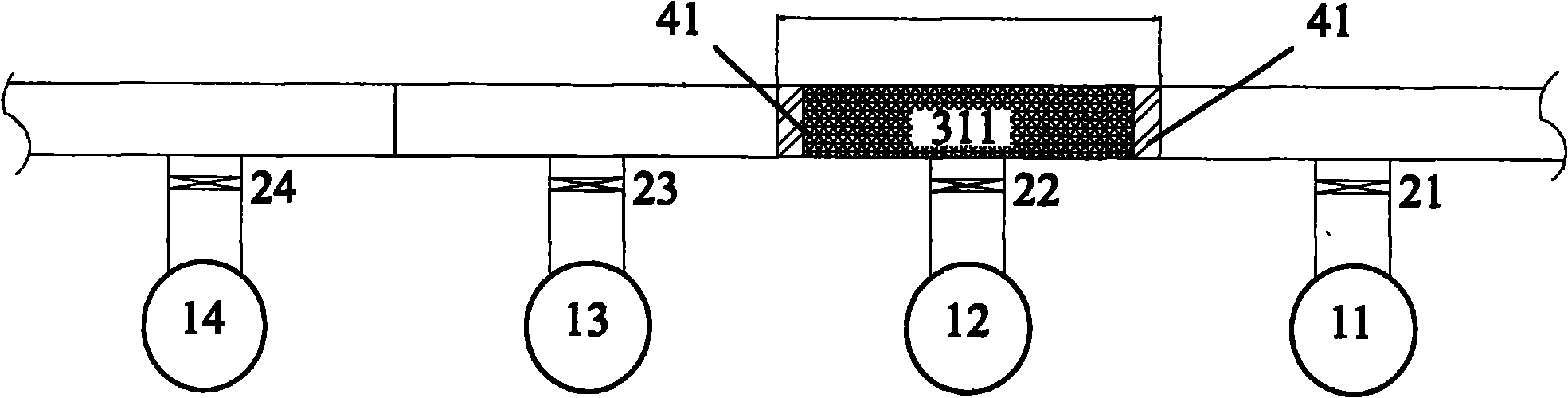

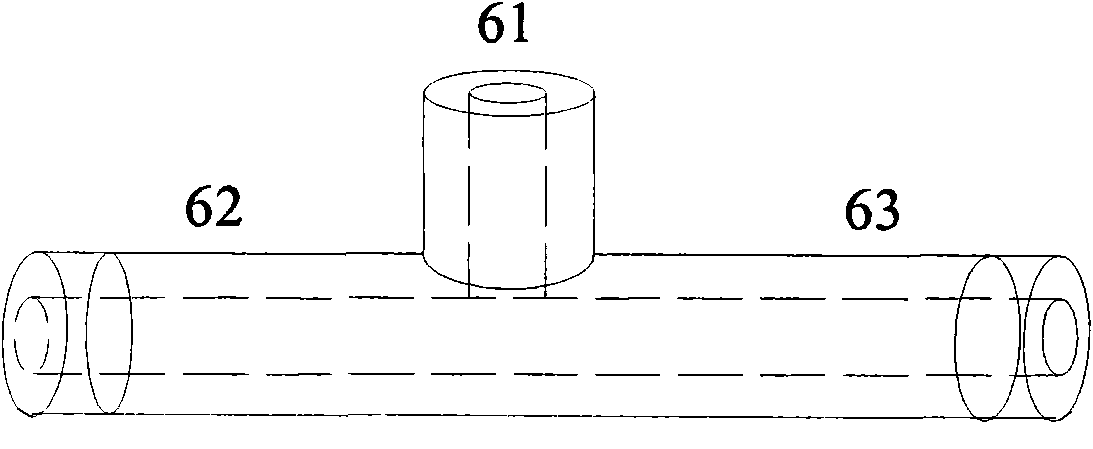

[0022] Such as figure 1 As shown, the hot blast stove 11, the hot blast stove 12, the hot blast stove 13 and the hot blast stove 14 are respectively connected on the hot blast main pipe 31 by the hot blast valve 21, the hot blast valve 22, the hot blast valve 23 and the hot blast valve 24. The section 311 of the hot blast main pipe needs to be replaced, and an expansion joint 41 is installed on both sides of the section 311 of the hot blast main pipe to be removed. The online replacement method of the hot blast main pipe of the blast furnace is adopted. After the hot blast stove is shut down and the energy medium pipelines are closed, follow the steps below: Remove the hot air main pipe → seal the pipe openings at both ends of the unremoved section → build the tee part of the hot air main pipe on the ground → hoist the hot air main pipe → build the hot air main pipe online → remove the heat insulation sealing wall, the specific steps are:

[0023] When dismantling the hot blas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com