Remote monitoring system for oil well pressure by capillary steel pipes

A technology of capillary steel pipe and monitoring system, which is applied in measurement, wellbore/well components, earthwork drilling and production, etc. It can solve the problems of oil production personnel in the working environment, emergency plan for production facility damage, difficulty in starting in time, etc., and achieve maintenance calibration Convenience, guaranteed integrity and reliability, improved dynamic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

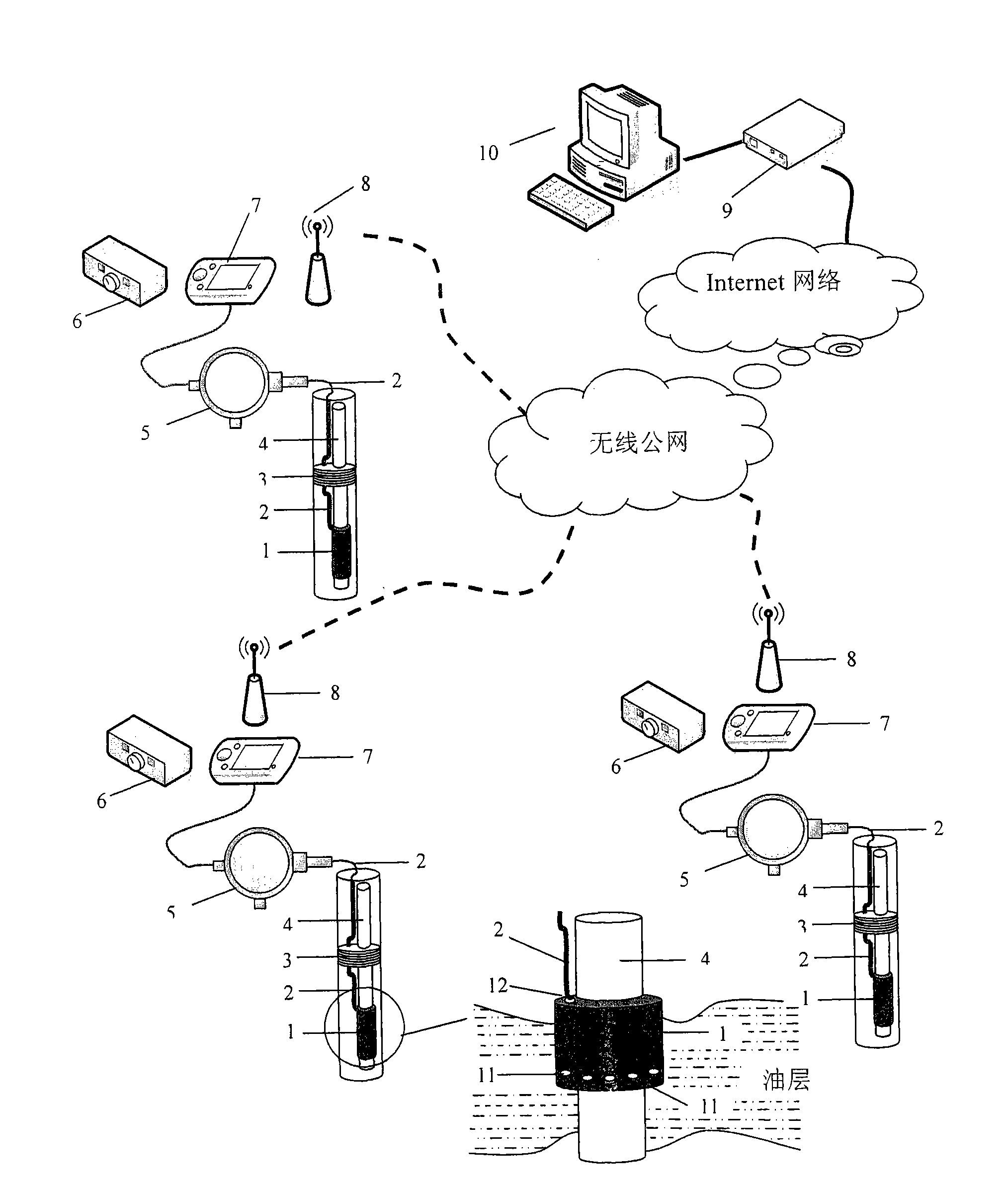

[0023] A remote monitoring and monitoring system for oil well pressure based on a distributed network structure of the present invention is a special system for remote monitoring and monitoring of oil well platform pressure parameters in ocean or desert environments. constitutes a main part.

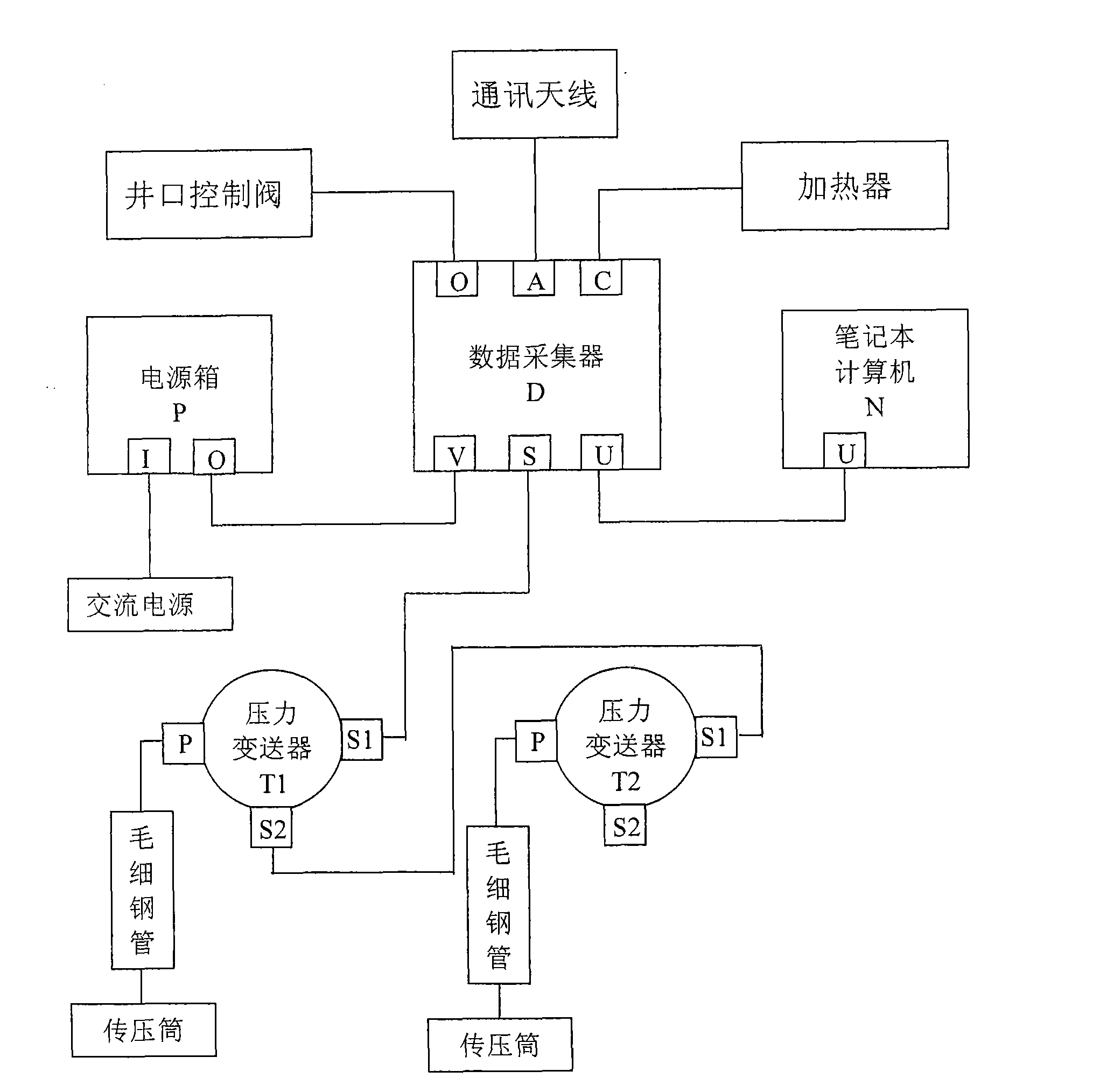

[0024] figure 1 It is the structural composition diagram of the monitoring and monitoring system. The capillary pressure measuring equipment is mainly composed of the surface part and the downhole part. Among them, the capillary pressure measuring equipment is composed of downhole pressure transmission cylinder 1 and capillary steel pipe 2, both of which contain filling gas such as nitrogen or helium; the surface collection terminal consists of pressure transmitter 5, data The collector 7 and the power supply box 6 consist of a pressure transmitter 5 including a pressure sensor, an explosion-proof casing and an RS232 serial port, and the data collector 7 includes a display screen, a dat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com