Printing head for 3D printing of powder material

A powder material and 3D printing technology, applied in the field of 3D printing, can solve problems such as inability to realize pressure changes, unfavorable molding of temperature-sensitive materials, and increased structural complexity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

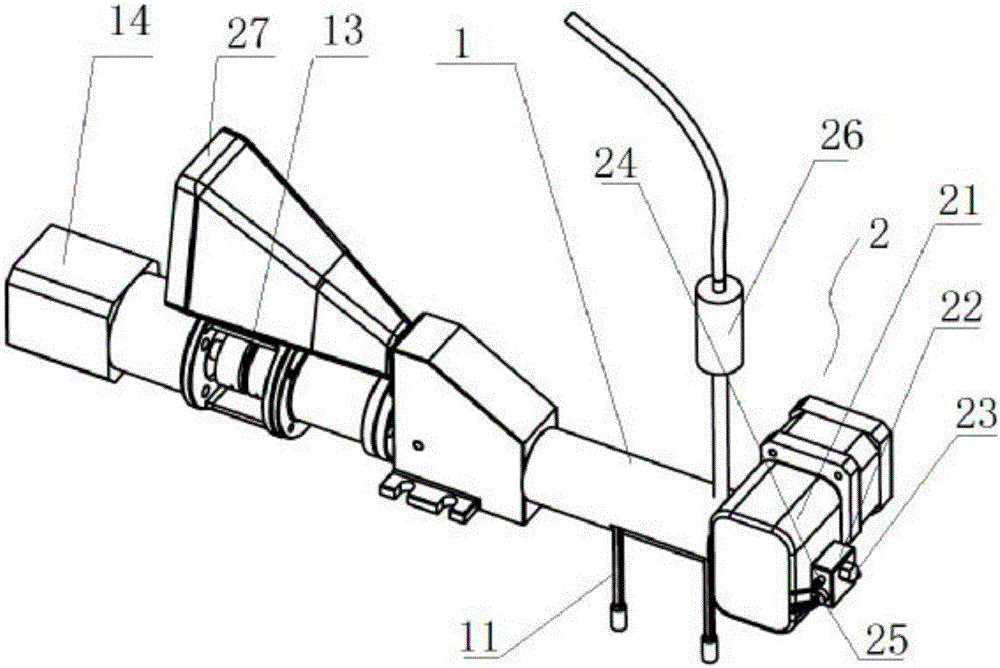

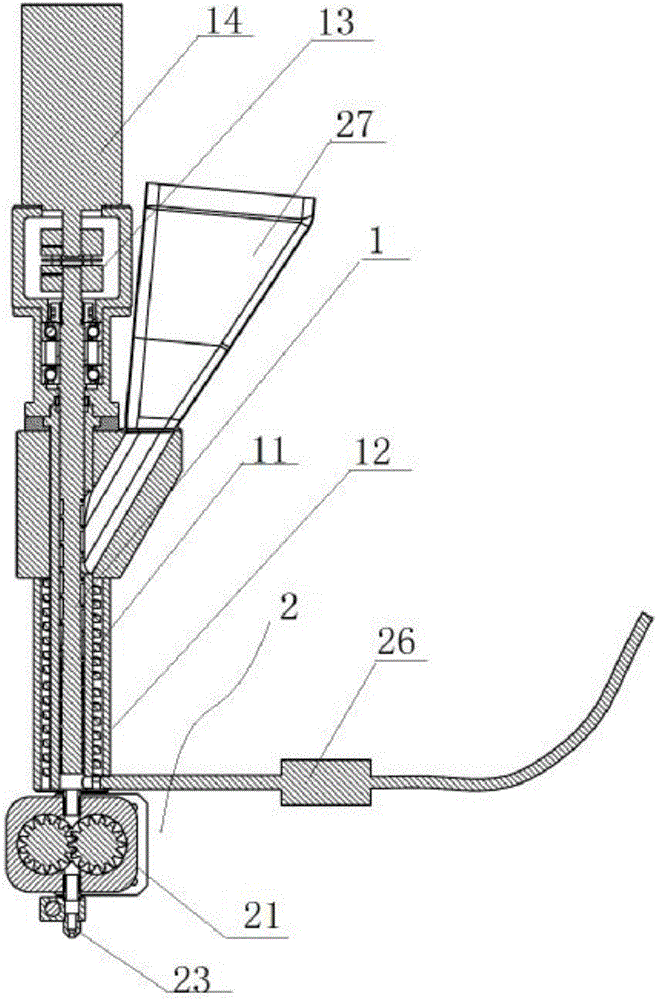

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

[0017] like figure 1 , figure 2 A printing head for 3D printing powder materials shown, including a melting extrusion mechanism 1, a printing head 2 connected to the melting extrusion mechanism 1 and a driving mechanism, the melting extrusion mechanism 1 is used to deliver heated and melted materials to the printing head 2 powder material, the driving mechanism is used to drive the melting extrusion mechanism 1; the print head 2 includes a gear pump 21 connected with the melting extrusion mechanism 1, and the outlet of the gear pump 21 is connected with the nozzle mechanism, and the nozzle mechanism includes a gear pump 21 connected with the gear pump 21. The nozzle base 22 is installed with a nozzle 23 communicating with the gear pump 21 inside the nozzle base 22. A heating rod 24 and a temperature sensor 25 are also installed inside the nozzle base 22. The melt ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com