Upper screw lower connecting pile fastener and precast member

A prefabricated, top-joining technology, applied in sheet pile walls, infrastructure engineering, construction, etc., can solve the problems of reducing concrete strength, prone to pile breakage, corrosion, etc., to ensure safety factor and safety, and ensure integrity. and strength, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

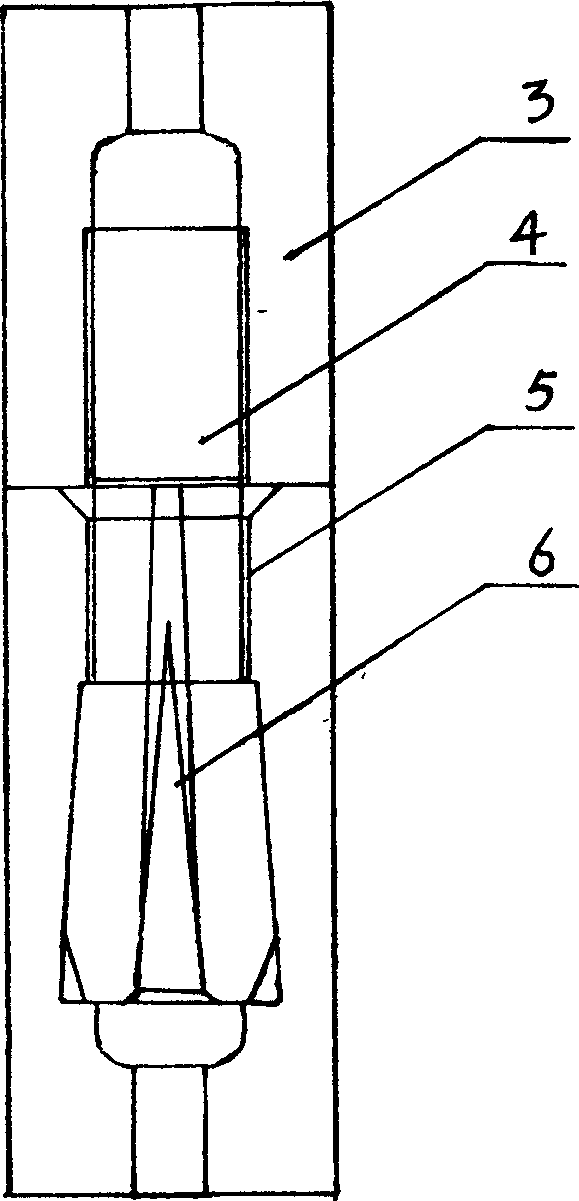

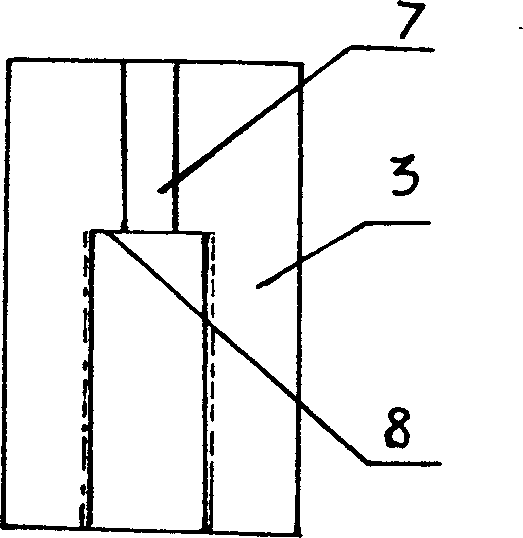

[0020] Embodiment 1: with reference to attached Figure 1~6 . The upper screw and the lower top pile buckle are composed of an expansion nut 3, an expansion screw 4 and a top tension nut 5. The expansion nut 3 is screwed on the screw section of the expansion screw 4. When docking, the expansion body of the expansion screw 4 expands. In the expansion chamber in the top pull nut 5, see attached figure 1 . The tension nut 3 adopts metal (such as steel, stainless steel, alloy steel, etc.) or non-metallic materials (such as high-strength plastics, high-strength synthetic plastics, ceramics, etc.) to make by existing casting or injection molding or ceramic firing or machining technology , the center of the cap bottom of the tension nut is provided with a steel bar hole 7, the periphery of the steel bar hole 7 is a steel bar heading card platform 8, and the threaded thread in the threaded nut 3 is a threaded thread for the strong tensioned pile, and the strong tensioned steel bar ...

Embodiment 2

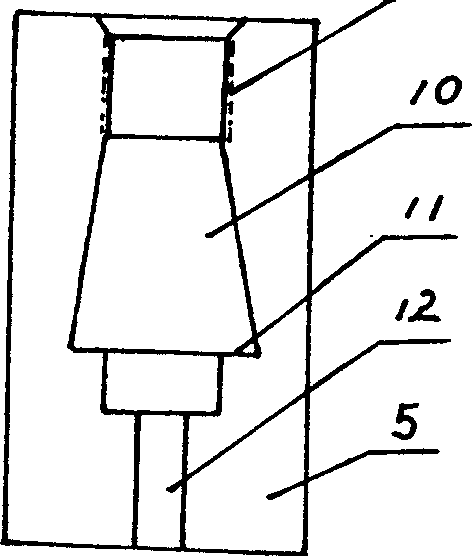

[0021] Embodiment 2: with reference to attached Figure 7 . On the basis of Embodiment 1, the prestressed high-strength pipe pile (round pipe, square pipe pile, etc.) formed by the upper screw and the lower pile buckle, the pipe pile 17 is built with several longitudinal steel bars 1 and circumferential steel bars 18 Constitute the pipe pile skeleton, the upsetting heads 2 at both ends of several longitudinal steel bars 1 in the pipe pile are respectively clamped on the expansion nut 3 and the top tension nut 5 on the steel bar upsetting heads 8 and 11, and the screw section of the expansion screw 4 Screwed in the expansion nut 3 (when the expansion screw 4 is docked with the pipe pile, the screw section of the expansion screw is screwed in the expansion nut 3; when the pipe pile is not connected with the pipe pile, its expansion The screw 4 is separated from the tension nut 3 and kept separately).

Embodiment 3

[0022] Embodiment 3: with reference to attached Figure 8 . On the basis of Examples 1 and 2, the pile connection structure between the prestressed high-strength pipe pile and the pipe pile, or between the bridge pier and the bridge pier, or between the utility pole and the utility pole, which is composed of the upper screw and the lower jacking pile buckle, needs to be connected. The ends of the two pipe piles of the pile are respectively a number of expansion nut openings and corresponding top tension nut openings. The screw section of the expansion screw is screwed into the screw thread of the expansion nut, and the expansion screw The expansion body is inserted into the expansion cavity of the top pull nut, and the expansion body is expanded in the expansion cavity of the top pull nut under the action of the expansion pin at the end, and the pile connection between the pipe piles is completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com