Lithium-ion-battery negative electrode slurry, preparing method thereof and preparing method of negative electrode plate

A lithium-ion battery and negative electrode slurry technology, which is applied to battery electrodes, circuits, electrical components, etc., can solve the problems of poor stability of negative electrode slurry, water absorption, flocculation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The preparation method of lithium-ion battery negative electrode slurry comprises the steps of mixing, gelling, pulping and homogenizing, wherein any step in the steps of mixing, gelling, pulping and homogenizing is added at one time or in batches Acidic compound additive, the molecular weight of the acidic compound additive is 90-200000, the addition amount of the additive is 0.3%-3% of the weight of the negative electrode active material, the state of the acidic compound additive can be solid powder, soft gel or organic in solution.

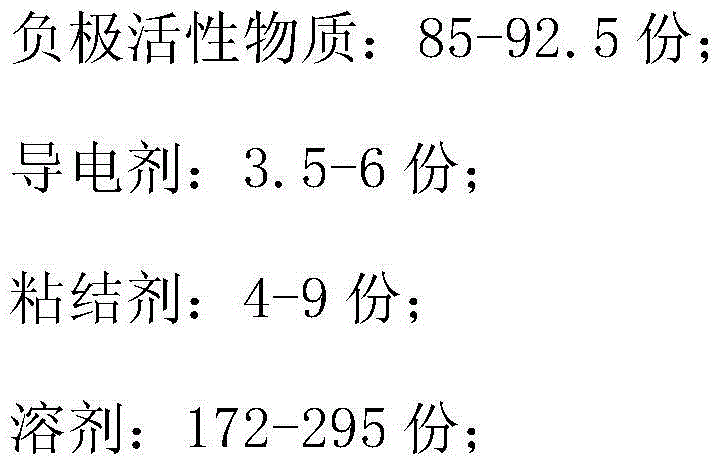

[0021] In the above scheme, the negative electrode active material lithium-titanium composite oxide Li 4 Ti 5 o 12 The proportioning of negative electrode slurry is by weight: Li 4 Ti 5 o 12 Additives with acidic compounds: 85%-92.5%, PVDF (polyvinylidene fluoride): 3.5%-6%, conductive carbon black: 4%-9%.

[0022] A lithium-ion battery negative pole piece, the pole piece is made by coating the above-mentioned lithium-ion battery n...

Embodiment 1

[0025] Lithium titanium composite oxide Li 4 Ti 5 o 12 The proportioning of the negative electrode slurry is calculated as 100% based on the total weight of the slurry: (lithium-titanium composite oxide Li 4 Ti 5 o 12 + acidic compound additive): PVDF: conductive carbon black=85%: 6%: 9%, wherein the consumption of acidic compound additive is 0, and glue making is after adding solvent NMP (N-methylpyrrolidone) in binder PVDF , PVDF: NMP=2%: 98%, stirring and mixing for 3h under the condition of stirring frequency of 10-20Hz, pulping is adding conductive agent, lithium-titanium composite oxide Li 4 Ti 5 o 12 Afterwards, stir for 6 hours under the condition of a stirring frequency of 20-40 Hz, and further stir for 1.5 h under the condition of a stirring frequency of 10-15 Hz for the homogenate.

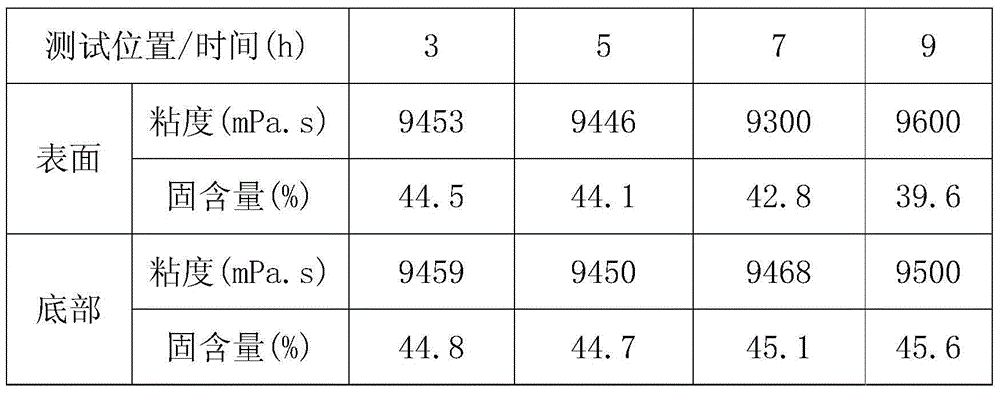

[0026]The ambient temperature is 25° C. and the humidity is 30% RH. The stability of the prepared negative electrode slurry is compared by testing the sieving rate of the slurry ...

Embodiment 2

[0032] Lithium titanium composite oxide Li 4 Ti 5 o 12 The proportioning of the negative electrode slurry is calculated as 100% based on the total weight of the slurry: (lithium-titanium composite oxide Li 4 Ti 5 o 12 +acidic compound additive): PVDF: conductive carbon black=85%: 6%: 9%, wherein the consumption of acidic compound additive oxalic acid is 0.3%, and the compounding is that the negative electrode active material lithium-titanium composite oxide Li 4 Ti 5 o 12 , acidic compound additive oxalic acid, and conductive agent were stirred and mixed for 1 hour under the condition of a stirring frequency of 10-20 Hz. The glue was made by adding solvent NMP to the binder PVDF, PVDF:NMP=2%:98%, and stirring Stir and mix for 3 hours under the condition of frequency 10-20Hz, pulping is to add the mixed material and stir for 6 hours under the condition of stirring frequency of 20-40Hz, homogenization is to further stir for 1.5 hours under the condition of stirring frequen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com