Electron buffering material and organic electroluminescent device comprising the same

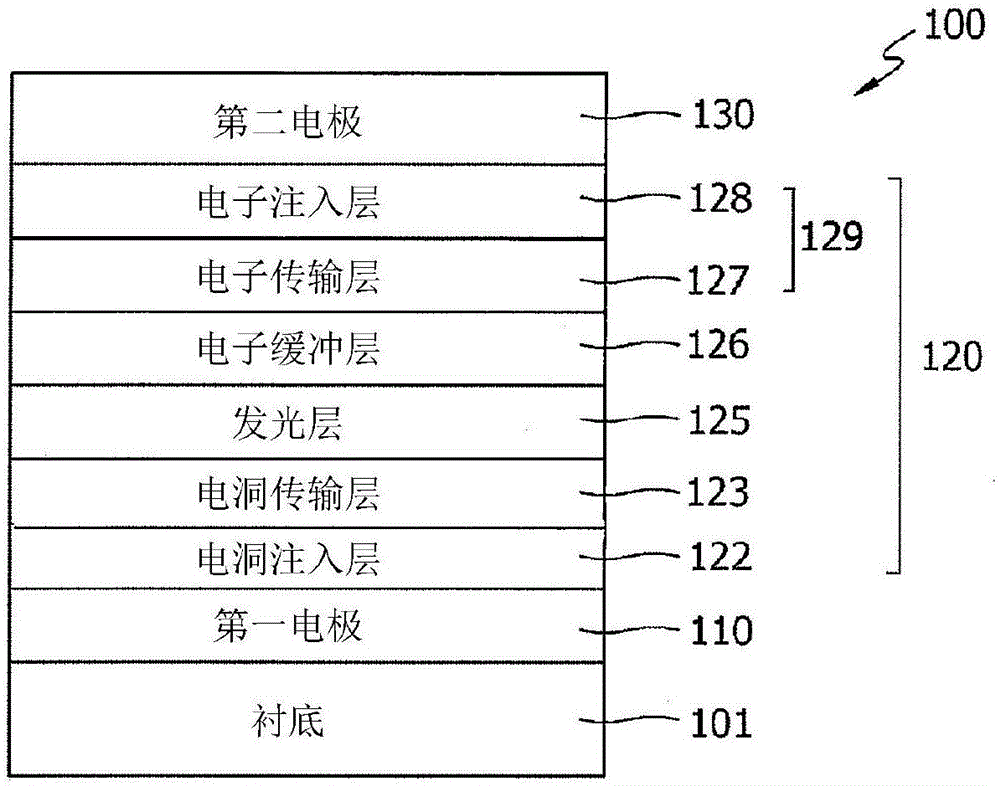

一种电子缓冲、致发光的技术,应用在有机化学、发光材料、电路等方向,能够解决材料群组小、限制、电子缓冲材料受限等问题,达到极佳发光功效、极佳使用寿命特征的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

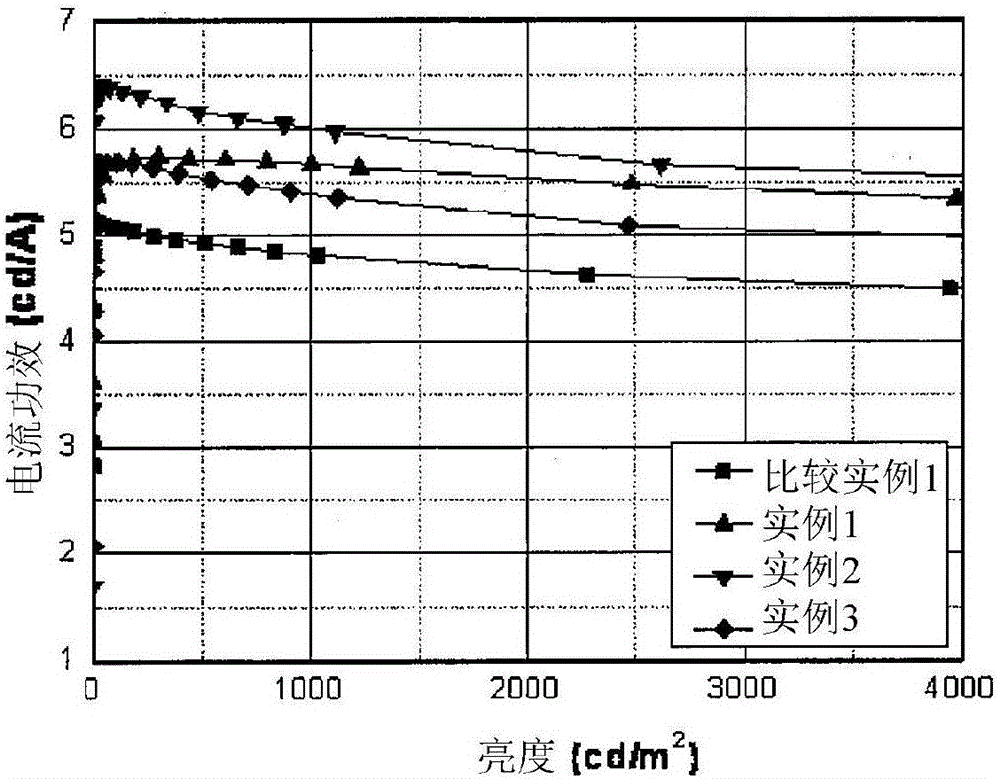

[0130] The measurement results of driving voltage, luminous efficacy, CIE color coordinates, and service life of Examples 1 to 3 and Comparative Example 1, and LUMO and HOMO values of the electron buffer layer are shown in Table 1.

[0131] [Table 1]

[0132]

[0133]

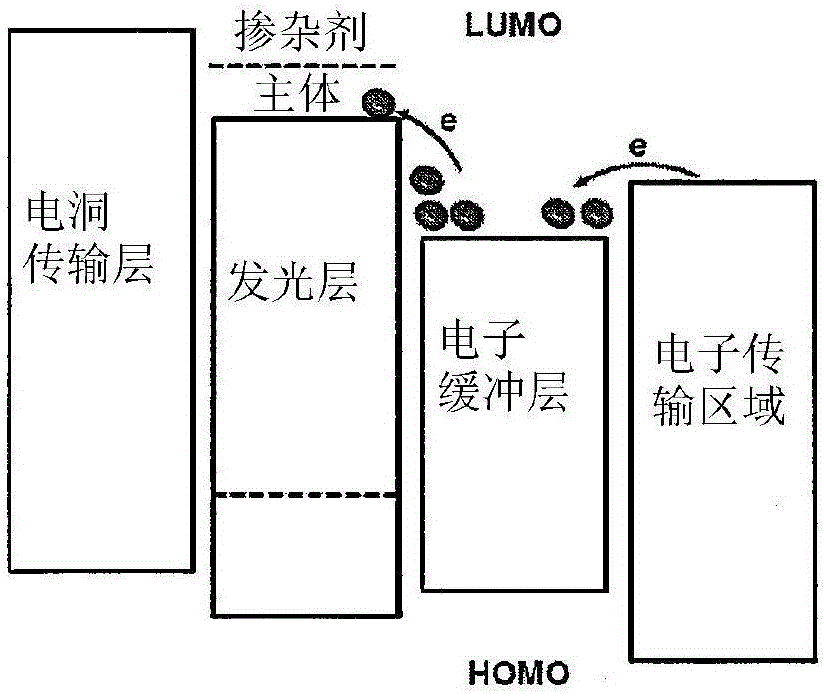

[0134] In Examples 1 to 3, the median value of the LUMO energy level of the electron buffer layer was 1.9 eV or higher, so that the electron injection barrier at the interface between the light emitting layer and the electron buffer layer was minimized to exhibit fast electron injection characteristics, Simultaneously exhibits similar voltage characteristics compared to Comparative Example 1. Specifically, the LUMO levels of Examples 1 and 2 were maintained at 1.8 eV and suitable electron injection characteristics were obtained in order to exhibit high efficacy. On the contrary, the service life of Examples 1 to 3 was similar to that of Comparative Example 1.

[0135] Examples 4 to 7: Organic electr...

example 4

[0139] The measurement results of driving voltage, luminous efficacy, CIE color coordinates, and service life of Examples 4 to 7 and Comparative Example 1, and LUMO and HOMO values of the electron buffer layer are shown in Table 2.

[0140] [Table 2]

[0141]

[0142] In Examples 4 to 7, the LUMO level of the electron buffer layer is between the middle value of 1.9's eV and the high value of 2.0 eV, so that the electron injection barrier of the interface between the light emitting layer and the electron buffer layer has a large influence, and Slow electron injection characteristics were thus exhibited compared to Comparative Example 1. However, higher voltage characteristics were exhibited compared to Comparative Example 1. Therefore, injected electrons were relatively insufficient compared to holes, and the possibility of forming excitons decreased, thereby exhibiting lower efficacy compared with Comparative Example 1. However, a longer service life was exhibited compa...

example 8

[0147] The measurement results of driving voltage, luminous efficacy, CIE color coordinates, and service life of Examples 8 to 12 and Comparative Example 1, and the LUMO and HOMO values of the electron buffer layer are shown in Table 3.

[0148] [table 3]

[0149]

[0150] In Examples 8 to 12, the LUMO level of the electron buffer layer was formed at a median value of 1.9 eV, and an electron injection barrier was applied at a certain level so that suitable electron injection characteristics were exhibited, which satisfied the efficacy and service life. Therefore, higher efficacy and longer service life were exhibited compared to Comparative Example 1. Specifically, excellent lifetime characteristics, ie, 1.5% or more higher than that of Comparative Example 1 were exhibited, while exhibiting high efficacy.

[0151] The use of electron buffer layers comprising triazine derivatives is advantageous for proper efficacy and lifetime.

[0152] Examples 13 to 15: Organic elec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com